Inside Ascend Elements’ hydro-to-cathode recycling process, they use water-based methods to recover key battery materials like lithium, nickel, and cobalt efficiently. Instead of relying on energy-intensive smelting, their technique dissolves cathode components selectively with water leaching, reducing waste and harmful emissions. The process produces high-purity materials that can be directly reused in new batteries. Learning more reveals how this innovative approach is transforming sustainable battery recycling and helping secure resources for the future.

Key Takeaways

- Utilizes water-based leaching to selectively extract cathode materials from used batteries.

- Avoids traditional high-temperature and chemical-intensive steps, reducing environmental impact.

- Purifies dissolved materials into high-quality precursors suitable for new battery production.

- Ensures high purity and safety standards for recycled cathodes, supporting industry performance.

- Promotes sustainability by conserving resources and minimizing waste through a circular recycling process.

To address the growing demand for sustainable battery materials, Ascend Elements has developed a groundbreaking hydro-to-cathode recycling process. This innovation transforms how we recover critical materials from used batteries, making recycling more efficient and environmentally friendly. When you consider the supply chain challenges and environmental impacts of traditional methods, it’s clear why this process stands out. Instead of relying on energy-intensive smelting or hazardous chemical treatments, Ascend’s method uses water-based extraction techniques that markedly reduce waste and emissions. This approach not only conserves resources but also ensures that valuable materials are reclaimed with high purity, ready for reuse in new batteries.

You might wonder how this process fits into the broader landscape of recycling innovations. What sets Ascend apart is its ability to directly recover cathode materials, the core components that determine a battery’s performance. By focusing on battery materials at this critical stage, they bypass the lengthy and costly steps associated with traditional recycling. Their hydro-to-cathode method simplifies the process, enabling faster turnaround times and less energy consumption. This means you get a more sustainable supply of essential materials like lithium, nickel, and cobalt, all while reducing reliance on mined resources. It’s a win-win for both the environment and the industry.

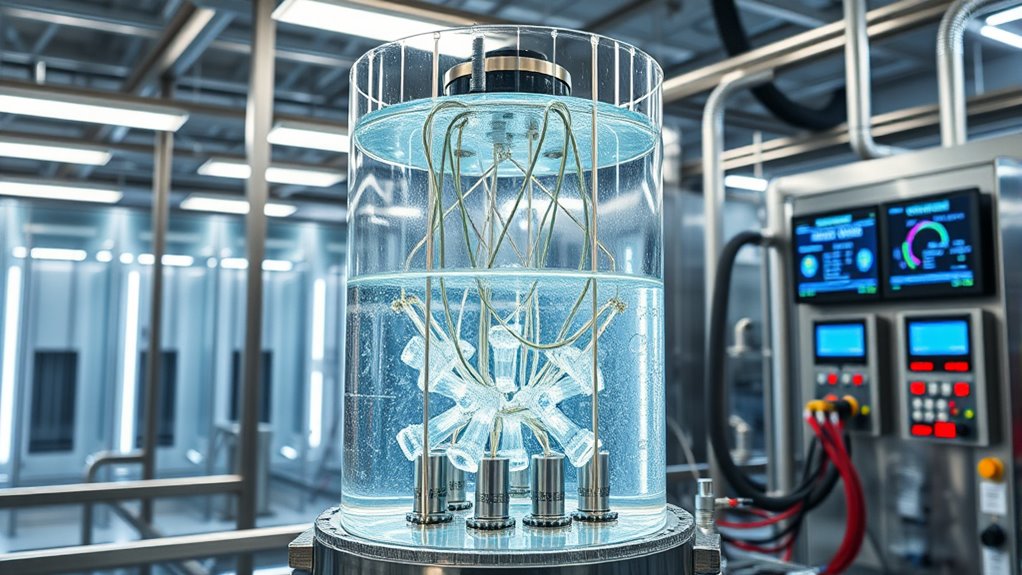

The process begins with collecting and preparing spent batteries, which are then subjected to a series of water-based leaching steps. These steps dissolve the cathode materials selectively, allowing the extraction of high-value compounds without damaging other components. You don’t need harsh chemicals or high temperatures, which minimizes the environmental footprint. Once the materials are dissolved, they’re purified and reconstituted into usable cathode precursors. These precursors can be directly incorporated into new battery manufacturing, closing the recycling loop efficiently. This cycle not only conserves natural resources but also cuts down on waste going into landfills.

Furthermore, advancements in the color accuracy of the process can help improve the visual quality of the recycled materials, ensuring they meet industry standards for performance and safety.

Frequently Asked Questions

What Are the Environmental Benefits of This Recycling Process?

You benefit from this recycling process because it improves battery purity, ensuring higher-quality materials while reducing reliance on virgin resources. It also substantially cuts emissions by using water-based methods instead of harmful chemicals. This approach helps lower your carbon footprint and supports a cleaner environment. Plus, it promotes sustainable practices, making your battery lifecycle more eco-friendly and aligned with your commitment to reducing environmental impact.

How Does the Process Compare Cost-Wise to Traditional Methods?

They say “a penny saved is a penny earned,” and that’s true here. Your process offers better cost efficiency compared to traditional methods, reducing expenses through streamlined operations. This improves the economic impact by lowering overall recycling costs and making sustainable practices more accessible. You’ll find that this innovative approach not only saves money but also supports environmental goals, proving you can be both eco-friendly and economically smart.

What Types of Lithium-Ion Batteries Can Be Recycled?

You can recycle a wide range of lithium-ion batteries, including those used in electric vehicles, portable electronics, and energy storage systems. The process helps recover valuable battery materials like lithium, cobalt, and nickel, but recycling challenges remain due to complex battery designs and varying chemistries. Addressing these challenges is vital for efficient recycling and maximizing material recovery, making it essential for sustainable battery lifecycle management.

How Scalable Is This Recycling Technology for Large Operations?

You might think scalability is a hurdle, but Ascend Elements’ process shows that it’s quite feasible for large operations. Their hydro-to-cathode recycling technology can be expanded with proper planning, addressing scalability challenges like supply chain and infrastructure. As industrial expansion continues, this method can adapt to meet increasing demand, making it a promising solution for sustainable lithium-ion battery recycling at scale.

What Are the Future Developments Planned for This Process?

You’ll see future developments focus on expanding battery reuse and process optimization. Ascend Elements aims to improve efficiency, reduce costs, and increase recycling capacity for larger operations. They plan to integrate advanced technologies that enhance material recovery and streamline workflows. These innovations will make the process more sustainable, scalable, and better suited to meet the growing demand for recycled battery materials, supporting a circular economy and accelerating electric vehicle adoption.

Conclusion

So, next time you marvel at shiny new batteries, remember the magic behind the scenes. Thanks to Ascend Elements’ hydro-to-cathode recycling process, we’re fundamentally turning used batteries into fresh ones—without mining more earth. It’s like recycling on steroids, making your old gadgets feel guilty for their wastefulness. Who knew that transforming spent batteries into future power sources could be so slick? Mother Earth, take a bow—your new favorite superhero just arrived.