When choosing a battery reconditioner, DIY kits are affordable and easy to use, making them great for occasional or small-scale projects. Commercial units are more expensive upfront but offer better reliability, efficiency, and support for a wider range of batteries, making them ideal for frequent or professional reconditioning. Understanding these differences helps you decide which option fits your needs and budgets. Keep exploring to discover which type could work best for you.

Key Takeaways

- DIY kits are cost-effective for occasional use but may require repeated attempts and additional supplies.

- Commercial units offer automated, user-friendly operation with consistent, reliable reconditioning results.

- DIY solutions suit small-scale or low-frequency reconditioning, while commercial devices are ideal for professional or frequent use.

- Long-term expenses favor commercial units due to durability, efficiency, and reduced labor time.

- Choice depends on reconditioning needs, budget, and desired outcome quality.

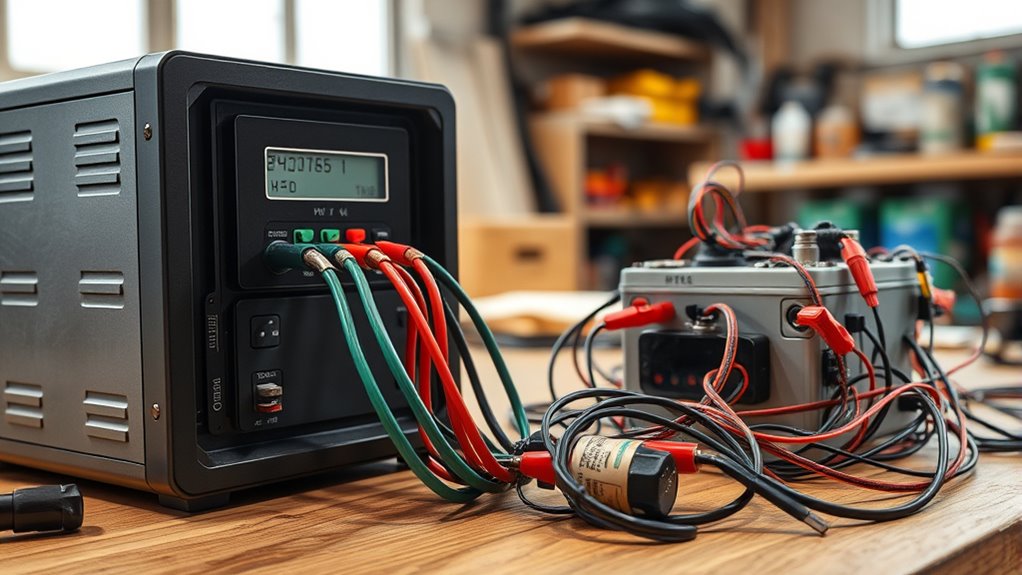

When it comes to restoring old or dead batteries, you have two main options: DIY reconditioning kits or commercial reconditioning units. Your choice depends on several factors, including cost effectiveness and user accessibility. DIY kits are typically more affordable upfront, making them an attractive option if you’re on a budget. These kits usually include basic tools and instructions, allowing you to attempt reconditioning without a significant financial investment. Because they’re designed for individual use, they tend to be straightforward, with clear step-by-step guides that anyone can follow, even if you lack technical experience. This simplicity enhances user accessibility, letting you recondition batteries at home without specialized training or equipment.

DIY battery reconditioning kits are affordable, user-friendly, and ideal for small-scale home use.

However, while DIY kits are cost-effective initially, you should consider the longevity and reliability of the results. Some kits may require multiple attempts or additional supplies, which can add to the overall expense over time. Additionally, their limited scope might not be suitable for all types of batteries or severe cases of degradation. Still, for small-scale or occasional use, DIY solutions are usually enough, especially if you’re comfortable following instructions and willing to invest some time.

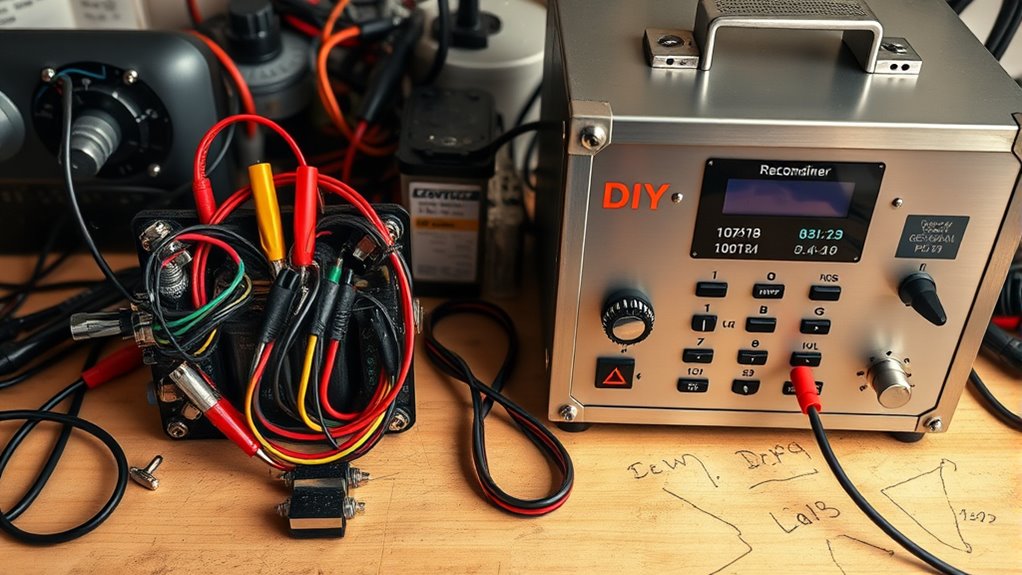

On the other hand, commercial reconditioning units tend to be more expensive but offer significant advantages in terms of efficiency and consistency. These devices are built with more sophisticated technology, often capable of handling a wider variety of battery types and more severe damages. They’re designed with user accessibility in mind, featuring user-friendly interfaces, safety mechanisms, and often automated processes that reduce the chance of errors. Although the initial investment is higher, commercial units can save you money in the long run by providing more reliable results and reducing the need for repeated attempts.

Furthermore, commercial reconditioning units are suitable for users who need to restore batteries regularly or in larger quantities, such as small businesses or service providers. Their efficiency and ease of use can make the reconditioning process faster and less labor-intensive, translating into better cost effectiveness over time. These units often include warranties and technical support, giving you peace of mind. While the upfront cost might seem intimidating at first, the durability, reliability, and ease of operation make commercial units an appealing choice if you’re planning to recondition batteries frequently or want a more professional approach.

In addition, understanding the contrast ratio of a device can help you determine how well it will perform in different lighting conditions, which is an important consideration for effective reconditioning.

Frequently Asked Questions

What Safety Precautions Should I Take When Using a Reconditioner?

When using a reconditioner, you should always wear personal protective equipment like gloves and goggles to avoid burns or sparks. Make sure your workspace is well-ventilated, clean, and free of clutter to prevent accidents. Keep the device away from water or flammable materials, and follow the manufacturer’s instructions carefully. Proper workspace setup and safety gear help you stay safe while effectively reconditioning your batteries.

How Long Does It Typically Take to Recondition a Battery?

It usually takes about 3 to 6 hours to recondition a battery, depending on its capacity and the extent of wear. During the reconditioning process, you’ll notice the battery gradually regains capacity as the chemical reactions restore its performance. Keep in mind, larger batteries or severely degraded ones may require longer, sometimes up to 12 hours, to fully recondition and restore peak capacity.

Can Reconditioning Extend a Battery’s Lifespan Significantly?

Yes, reconditioning can markedly extend your battery’s lifespan by restoring its health and performance. When you use the right techniques, you help remove sulfation and other issues that degrade capacity. This process can add months or even years to your battery’s life, saving you money and reducing waste. Regular reconditioning maintains ideal battery health, ensuring it continues to deliver reliable power and maximizes its overall lifespan extension.

Are There Any Warranties or Guarantees on Commercial Reconditioning Units?

Imagine your battery as a fragile promise, and a warranty as its safety net. Commercial reconditioning units often come with warranty policies and product guarantees, giving you peace of mind that your investment is protected. These assurances show the manufacturer’s confidence in their device’s performance. Always check the warranty details before purchasing, so you know you’re covered if the reconditioning doesn’t meet expectations or if issues arise.

How Do I Identify if My Battery Is Suitable for Reconditioning?

You can tell if your battery is suitable for reconditioning by considering its age and performing a visual inspection. Typically, if the battery is relatively new or has been used for less than a few years, chances are better. Look for signs like corrosion, leaks, or bulging, which indicate damage. If the battery shows minimal damage and isn’t overly old, there’s a good chance reconditioning could restore its functionality.

Conclusion

Whether you choose a DIY or commercial battery reconditioner, imagine the thrill of reviving a tired battery, like breathing new life into a dormant engine. Picture yourself confidently connecting wires, feeling the satisfaction of sparking vitality into an old, forgotten power source. As you watch the green lights flicker on, you realize you’re not just saving money—you’re restoring energy and purpose. With each reconditioning, you’re turning potential waste into renewed power, ready to keep your devices running smoothly.