Did you know that reconditioning batteries can extend their usable life by months or even years, reducing the waste generated from discarded batteries? This practice is not only cost-effective—often a fraction of what new batteries cost—but it also offers substantial environmental benefits through waste reduction1. In today’s world, where the demand for sustainable practices continues to grow, understanding the principles of old battery reconditioning could become essential. By learning how to breathe new life into your worn-out batteries, you can contribute to a more sustainable future while saving money and improving overall battery performance2. This guide will embark on a journey through battery restoration methods, the types of batteries you can recondition, and the necessary tools and safety measures for a successful DIY project.

Key Takeaways

- Reconditioning can significantly prolong battery life.

- It’s a cost-effective alternative to buying new batteries.

- Recognizing signs of battery fatigue is crucial for reconditioning.

- Several types of batteries, including lead-acid and lithium-ion, can be reconditioned.

- Using the right tools and safety gear ensures a successful process.

- Reconditioning supports environmental sustainability through waste reduction.

- Understanding battery chemistry is essential to avoid common mistakes.

What is Old Battery Reconditioning?

Old battery reconditioning is the process of restoring the functionality of various types of batteries, allowing them to regain lost capacity and performance. Understanding battery chemistry is essential for anyone looking to tackle this task effectively, as it explains how batteries function and what leads to their decline over time. For instance, batteries in the two-way radio industry typically should be replaced every 18 to 24 months for optimal performance3. With proper techniques, you can often restore old batteries to their full potential, offering numerous benefits.

Understanding Battery Chemistry

Battery chemistry involves the study of the materials and processes that generate electric power within batteries. Different batteries, such as lead-acid, lithium-ion, and nickel-metal hydride, all operate based on unique chemical reactions. Knowing the specifics of these reactions assists in recognizing the right methods for reconditioning. For instance, reconditioning can help eliminate the memory effect in batteries, which enhances their overall capacity and performance3. Proper management of the battery’s state during reconditioning can maximize operating times between charges and prolong its life cycle.

The Benefits of Reconditioning Your Old Batteries

The benefits of reconditioning your old batteries are substantial. Not only can you save money by reducing the frequency of battery replacements, but you also contribute to environmental sustainability by minimizing electronic waste. Reconditioning chargers monitor battery usage patterns, ensuring they only activate when necessary, thereby preserving battery life3. Proper reconditioning can restore up to 80% of high-quality lead-acid batteries’ capacity within a year and should be done more frequently for older batteries to maintain performance4. In addition, you can achieve longer periods of usability between charges while benefiting from the reconditioning process itself, which may take anywhere from 10 to 40 hours based on the battery type and condition34.

Types of Batteries You Can Recondition

Understanding the different types of batteries you can recondition is crucial for maximizing efficiency and extending battery life. Each battery type has unique characteristics and reconditioning methods that tailor the process to their specific needs.

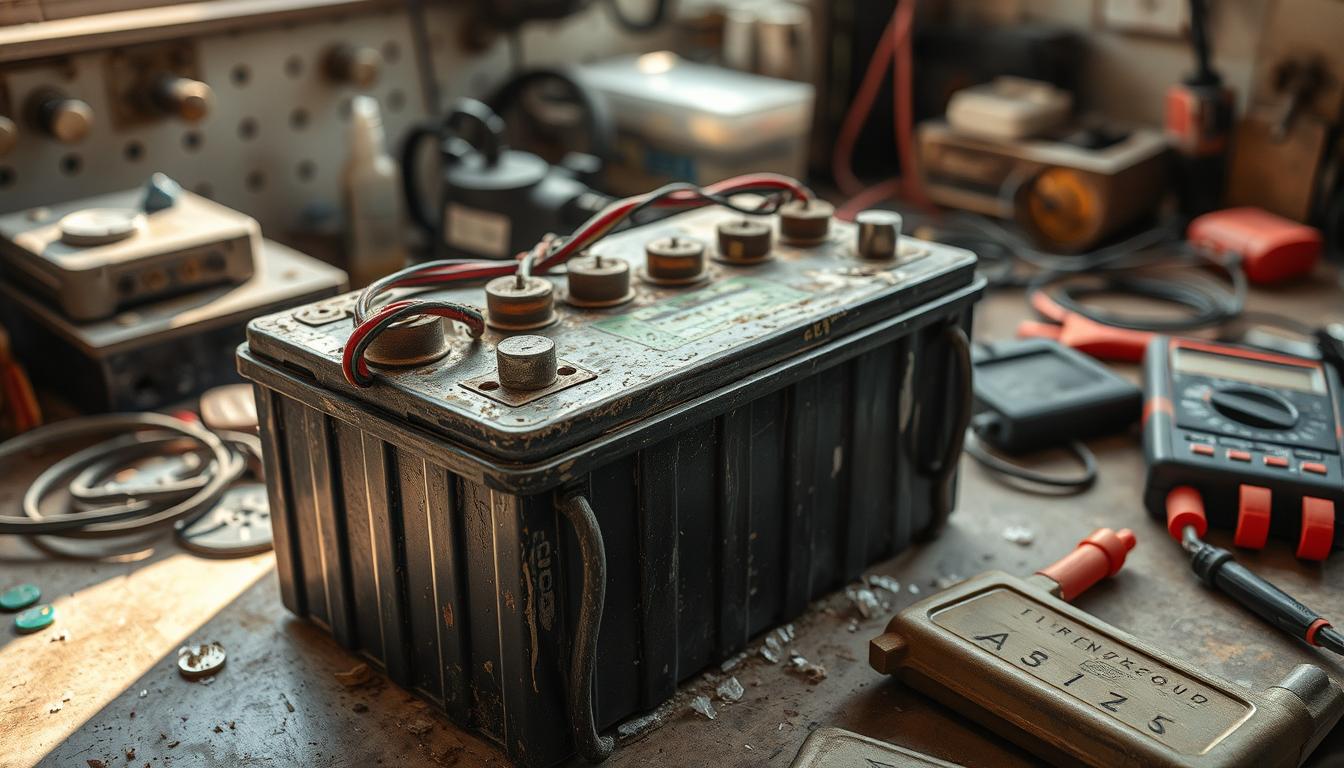

Lead-Acid Batteries

Lead-acid batteries, commonly used in industries such as renewable energy and automotive, can be reconditioned effectively. The reconditioning process involves restoring battery cells to their original condition, which can significantly extend their lifespan5. Techniques like desulfation and adding distilled water to flooded cells are instrumental in enhancing their performance5. In the market, automated lead-acid battery reconditioners are available to simplify this process for users5.

NiMH Batteries

For those interested in NiMH battery restoration, understanding cycle charging is key. This method enhances capacity while ensuring that the battery cells are balanced, leading to improved functionality over time. Investing in quality tools for this type of reconditioning can yield productive results.

Lithium-Ion Batteries

Lithium-ion rejuvenation requires specific techniques such as employing a balancing charger and managing the temperature during charge cycles. This meticulous attention to detail is essential to prevent damage and ensure long-lasting performance. Hybrid vehicle battery reconditioning can be a cost-effective solution compared to purchasing new batteries, with tools like the EVc-30 leading the market in effectiveness6.

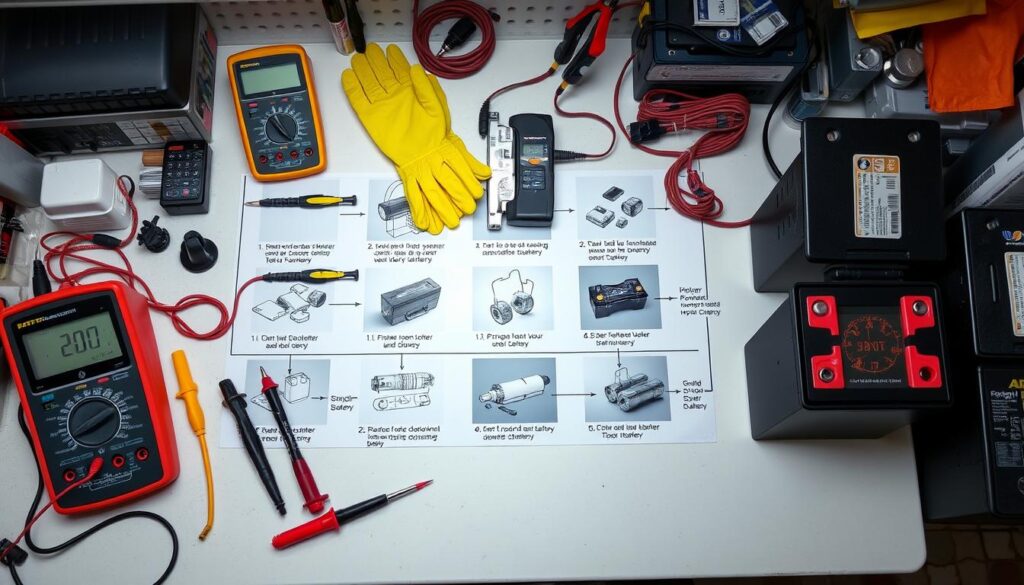

Tools and Materials Needed for Reconditioning

When embarking on the journey of old battery reconditioning, having the right tools and materials is crucial. Not only does it streamline the process, but it also ensures safety and effectiveness. Below, you’ll find essential tools, safety gear, and recommended chemicals that can help you achieve successful results in your reconditioning projects.

Essential Tools for the Job

Your toolkit should include several specific items to assist in the reconditioning process:

- Multimeter: Essential for measuring voltage levels accurately.

- Battery charger: A suitable charger tailored for the type of batteries you are working on.

- Screwdrivers and wrenches: For accessing battery terminals and compartments.

- Pulse charger or desulfator: These tools may help in some instances, though success varies.

- Hydrometer: Useful for checking the condition of lead-acid batteries.

Safety Gear Recommendations

Prioritizing safety is non-negotiable during the reconditioning process. Here’s a list of the necessary safety gear for reconditioning:

- Gloves: Protect your hands from acid and chemical spills.

- Goggles: Shield your eyes from potential splashes.

- Face mask: Helps avoid inhaling toxic vapors.

- Apron: A protective layer to keep your clothing safe from battery fluids.

Recommended Chemicals and Solutions

The effectiveness of battery restoration often relies on the materials you utilize. Here are some key substances:

- Distilled water: Essential for maintaining appropriate levels in lead-acid batteries.

- Baking soda solution: Can neutralize acid spills.

- Battery desulfation chemicals: This can aid in restoring battery health.

Using the appropriate tools for battery reconditioning, investing in quality safety gear for reconditioning, and selecting effective battery restoration materials can greatly enhance your chances of success. It’s advisable to prepare adequately before starting your reconditioning journey, ensuring you have everything you need on hand78.

Step-by-Step Guide to Recondition Lead-Acid Batteries

Reconditioning lead-acid batteries can be a rewarding process, allowing you to extend their lifespan effectively. This guide breaks down the lead-acid battery reconditioning steps into manageable parts, focusing on battery preparation, the reconditioning process, and testing the restored batteries.

Preparing the Battery

Before you dive into the reconditioning process, it’s crucial to perform proper battery preparation. Begin by checking the voltage levels of your battery; a healthy reading should indicate around 12.6V. Values between 10V and 12.6V suggest the battery is suitable for reconditioning9. Inspect the battery cells for any signs of sulfation or damage, and add 5ml of phosphoric acid per cell if needed to combat phosphate build-up. Manufacturers recommend an annual application of 2 to 2.5ml per cell for optimal maintenance10.

The Reconditioning Process

The actual reconditioning involves several key steps. Start by removing the cell caps and emptying the battery cells. Clean the cells using a paste made from a 2:1 mixture of baking soda and water9. Afterward, replace the electrolyte solution with a mixture of water and Epsom salts, and refill the cells. Charge the battery slowly for about 36 hours at 12V/2 amps. If you observe no improvement in the battery plates after initial charging, consider adding an additional 2.5ml of phosphoric acid per cell10.

Testing Your Reconditioned Battery

Once the reconditioning process is complete, you will need to conduct testing on the restored batteries. A successful reconditioned battery should exhibit a voltage reading around 12.42V9. To ensure the battery meets functional standards, test its performance under load, checking that it can sustain power output without significant drops in voltage.

| Step | Description | Process Duration |

|---|---|---|

| Preparation | Check voltage and inspect cells for sulfation. | 5–10 minutes |

| Cleaning | Clean cells with baking soda paste. | 30 minutes |

| Replace Electrolyte | Use water and Epsom salts mixture. | 15 minutes |

| Charging | Charge battery at 12V/2 amps. | 36 hours |

| Testing | Check voltage and performance under load. | 10 minutes |

Following these steps diligently helps maximize the efficacy of your lead-acid battery reconditioning efforts, ensuring your batteries perform optimally and last longer10.

Common Mistakes to Avoid When Reconditioning

Reconditioning batteries can be a fantastic way to extend their life, but there are common battery reconditioning mistakes that can undermine your efforts. Recognizing these pitfalls is essential to ensuring success in the process.

Overcharging vs. Proper Charging

One of the most significant challenges faced during battery reconditioning is the risk of overcharging. Many beginners underestimate the importance of proper charging techniques. Overcharging can lead to serious overcharging dangers, including battery swelling, damage to the internal cells, and even potential safety hazards. It’s crucial to use the correct charger specific to your battery type and keep a close eye on the voltage levels throughout the charging process. Proper monitoring can be the difference between a successfully reconditioned battery and a damaged one. Make sure you are familiar with the expected voltage range for the specific battery you are working with to avoid this common mistake.

Ignoring Safety Precautions

When diving into battery restoration, safety in battery restoration should be your top priority. Neglecting safety precautions can lead to accidents, injuries, or equipment damage. Always wear appropriate protective gear, such as gloves and safety goggles, and work in a well-ventilated area to minimize exposure to harmful gases. It is also important to familiarize yourself with safety protocols associated with the battery type you are working on. By observing these critical safety measures, you can significantly reduce the risks associated with battery reconditioning and ensure a smoother process.

| Mistake | Consequence | Prevention Tip |

|---|---|---|

| Overcharging | Battery damage, swelling, leaks | Use proper charger, monitor voltage |

| Ignoring safety gear | Injuries, exposure to toxic materials | Wear gloves, goggles, and work in ventilated area |

| Using incorrect methods | Failed reconditioning, loss of battery use | Research battery-specific reconditioning techniques |

By avoiding these common mistakes, you can make the most of your reconditioning efforts and ensure your battery is restored effectively117.

How to Identify a Battery Worth Reconditioning

Identifying a battery that is worth reconditioning involves a careful battery condition assessment. You should look for signs of battery failure such as diminished runtime, slow charging phases, and unexpected overheating. Recognizing these indicators early can save you time and money.

Signs Your Battery Needs Reconditioning

The initial step in determining if your battery can be revived is to watch for certain signs. A few common indications of a failing battery include:

- Reduced runtime during usage

- Slow or inconsistent charging

- Unusual heat during charging cycles

If you notice any of these signs of battery failure, it may be time to consider reconditioning. A comprehensive battery condition assessment can lead to financial benefits. For instance, the annual expense of unnecessary battery replacements in the USA exceeds $650 million, emphasizing the need for a proactive approach to battery maintenance12.

Lifespan Expectations

Understanding the expected lifespan of batteries can further influence your decision to recondition. Typical reconditioning lifespan varies according to the battery type:

| Battery Type | Expected Lifespan | Reconditioning Potential |

|---|---|---|

| Lead-Acid | 3 years | Viable if maintained properly |

| Nickel-Based | 3 years | May benefit from reconditioning |

| Lithium-Ion | 5 years | High recovery potential |

Stationary batteries usually have a service life between 5 to 10 years, particularly in hotter climates. This longevity means many batteries may still possess a significant portion of their capacity, making them good candidates for reconditioning12.

Taking the time to assess these factors will ensure that your efforts in reconditioning yield the best possible results.

Storing Reconditioned Batteries Safely

Once you’ve successfully reconditioned your batteries, storing them safely becomes crucial for their longevity. Proper battery storage methods not only help in maintaining reconditioned batteries but also prevent potential hazards. Understanding safe storage methods can significantly extend the life of your batteries, allowing you to use them effectively when needed.

Best Practices for Storage

To ensure your reconditioned batteries remain in excellent condition, follow these best practices:

- Store batteries in a cool, dry place with a recommended ambient temperature of around 60°F13.

- Keep batteries upright to avoid electrolyte leakage13.

- Avoid stacking batteries to minimize the risk of damage and overheating.

- Utilize non-combustible and non-corrosive racking materials, favoring plastic pallets over wooden options13.

- Ensure proper ventilation in the storage area to dissipate any offgassing from stored batteries13.

- Keep flammable materials, such as cardboard and paper, away from stored batteries13.

How to Maintain Your Reconditioned Battery

Alongside safe storage, maintaining your reconditioned batteries is vital to their efficiency. Here are some tips:

- Regularly check the performance of your batteries to catch any problems early14.

- Monitor charge levels, ensuring they do not drop below a certain threshold to prevent permanent damage.

- Conduct periodic conditioning charge and discharge cycles as necessary based on their initial condition14.

- Look out for signs of age-related capacity loss, which can occur due to temperature fluctuations and charging habits14.

Environmental Benefits of Reconditioning Batteries

Reconditioning old batteries offers remarkable advantages for the environment. By embracing sustainable battery practices, individuals can significantly contribute to reducing electronic waste. When you refurbish batteries instead of discarding them, you help minimize pollution and promote a healthier ecological balance.

Reducing Waste and Pollution

The reconditioning process involves restoring used batteries to their original functionality, extending their lifespan and reducing the frequency of replacements needed. This practice not only results in significant cost savings for businesses by reducing maintenance costs but also lessens the landfill contributions associated with battery disposal, aligning with the environmental impact of battery reconditioning15. Refurbished batteries offer environmental benefits by reducing waste, minimizing pollution levels, and alleviating the need for new battery production, which can be energy-intensive and harmful to the planet16.

Promoting Sustainability

As technology advances, the reliability of reconditioned batteries has improved. High-quality, reconditioned batteries are usually more affordable than brand new ones, providing immediate cost reductions for individuals and businesses15. Utilizing reconditioned batteries not only helps budget-conscious consumers but also supports the movement towards sustainable energy practices. Regular maintenance of these batteries can maximize their lifespan and efficiency, contributing to sustainability goals by reducing the overall demand for new battery manufacturing16.

| Benefits of Reconditioning Batteries | Details |

|---|---|

| Cost Savings | Reduces maintenance costs for businesses and is financially appealing to consumers. |

| Longevity | Reconditioned batteries can last for an additional year or two with proper care. |

| Environmental Protection | Helps reduce pollution by minimizing hazardous waste from battery disposal. |

| Sustainable Practices | Supports the recycling and restoration of used batteries, promoting a circular economy. |

The Future of Battery Reconditioning

The landscape of battery reconditioning is evolving, driven by advancements in future battery technology. Innovations in battery reconditioning are paving the way for methods that enhance efficiency, capacity, and longevity of batteries, which is crucial as the demand for energy storage continues to rise.

Innovations in Battery Technology

As we look towards the future, several developments stand out. The automotive industry is gearing up for significant transformations; by 2025, we expect up to 250 new electric vehicle (EV) models, featuring batteries from more than 15 manufacturers17. These second-life batteries are projected to generate a storage application market valued at over $30 billion by 203017. Not only will these innovations change how we view battery life cycles, but they will also enhance the economic value of battery reconditioning.

The Role of Reconditioning in a Circular Economy

The principles of a circular economy underscore the importance of battery reconditioning. By keeping lead-acid batteries in a closed-loop system, almost 100% of them can be recycled, promoting sustainability in various sectors18. This practice minimizes waste while simultaneously providing cost-effective solutions to businesses and consumers alike. Automakers are starting to design EVs with second-life applications in mind, allowing for the refurbishment of old batteries and maximizing their value17. This not only extends the lifecycle of batteries but also aligns profit with efficient resource use, paving the way for a more sustainable model of consumption.

Conclusion: Taking Action on Old Battery Reconditioning

Engaging in old battery reconditioning action presents an incredible opportunity for you to not only save money but also contribute positively to the environment. By extending the life of your batteries, you can significantly reduce the need for new purchases, which, according to data, equates to nearly 19 pounds of waste avoided per person annually19. Moreover, the process helps minimize the solid waste generated by lead-acid batteries, which accounts for a staggering 2.8 million tons every year in the United States19. This eco-friendly practice not only benefits your wallet but also promotes sustainability by addressing the alarming pollution associated with battery disposal.

Final Thoughts and Encouragement

As you ponder the steps for starting reconditioning projects, remember that each small action can lead to substantial improvements over time. The reconditioning process, generally taking about 2-3 hours20, can set you on a rewarding battery restoration journey where you learn valuable skills while fostering a sustainable lifestyle. By sharing your experiences and results with others, you not only inspire them but also contribute to a community that champions environmental stewardship.

Getting Started with Your Reconditioning Journey

Getting started with your reconditioning projects is simpler than you might think. Equip yourself with essential tools, follow the systematic reconditioning steps, and take necessary safety precautions to ensure a successful outcome. You’ll find that regular maintenance can extend your battery’s life dramatically, potentially allowing a reconditioned battery to function effectively for over three to five years19. So, take that first step today and become part of a movement towards a cleaner, more sustainable future through effective old battery reconditioning.