Hybrid lithium-ion capacitors combine the high energy density of lithium-ion batteries with the fast charge-discharge power of supercapacitors. You can expect them to deliver quick bursts of energy while providing longer-term power storage. This balance makes them ideal for applications like electric vehicles and portable electronics. As you explore further, you’ll discover how advanced materials and manufacturing techniques enhance their performance and longevity for versatile energy solutions.

Key Takeaways

- Hybrid lithium-ion capacitors integrate battery-like energy density with supercapacitor-like fast charge-discharge capabilities.

- They balance high energy storage with rapid power delivery through specialized electrode materials.

- Electrode design, combining materials like carbon and lithium transition oxides, enhances both energy and power performance.

- Manufacturing techniques ensure electrode uniformity and stability, critical for long-term, high-performance operation.

- These devices are ideal for applications requiring quick energy bursts and sustained power, such as electric vehicles and portable electronics.

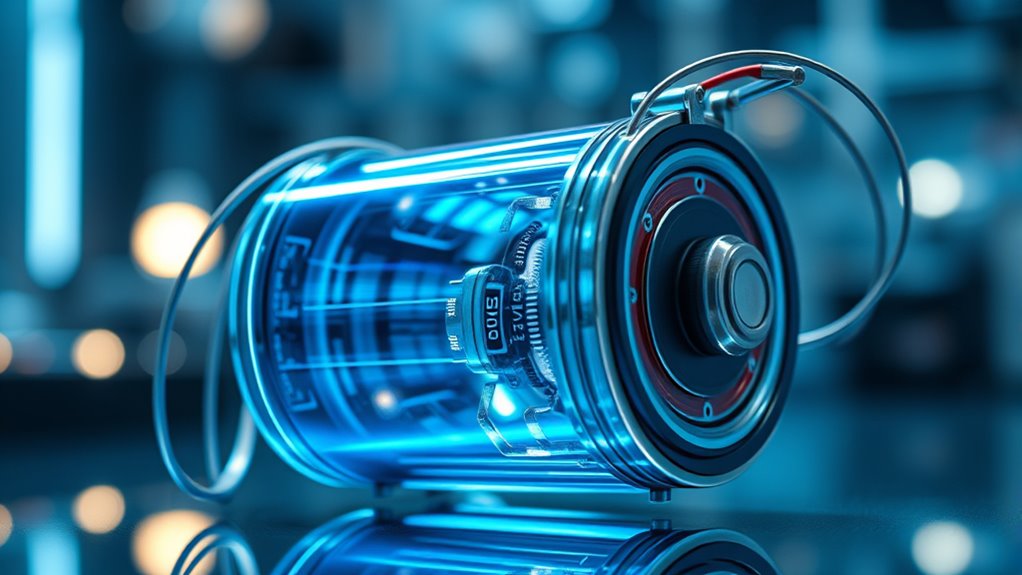

Hybrid lithium-ion capacitors combine the high energy density of lithium-ion batteries with the fast charge-discharge capabilities of supercapacitors. This unique blend offers a practical solution for applications requiring both power and energy, such as electric vehicles and portable electronics. To achieve this, the choice of electrode materials is vital. You’ll find that electrode materials in these capacitors are carefully engineered to balance energy storage and power delivery. Typically, the anode uses carbon-based materials like activated carbon or graphene, which provide high surface area for rapid charge transfer. The cathode often incorporates lithium transition metal oxides or phosphates, which can store significant amounts of energy. These materials are selected not only for their electrochemical properties but also for their stability over many charge-discharge cycles.

Hybrid lithium-ion capacitors blend high energy density with rapid charge-discharge capabilities through carefully engineered electrode materials.

Manufacturing processes play a pivotal role in the performance and longevity of hybrid lithium-ion capacitors. You’ll notice that advanced techniques like slurry casting, roll-to-roll processing, and freeze-drying are employed to produce electrodes with uniform thickness and high porosity. These processes ensure that the electrode materials are well integrated with current collectors, reducing resistance and enhancing overall efficiency. furthermore, the manufacturing environment must be carefully controlled to prevent contamination and degradation of sensitive electrode materials. Precise control over parameters such as temperature, humidity, and drying conditions helps produce electrodes that meet strict performance standards.

When assembling the capacitor, you’ll find that the manufacturing process involves layering the electrodes with a separator soaked in electrolyte. The electrolyte, often a lithium salt solution, facilitates ion movement between electrodes during operation. Making sure the quality and consistency of the manufacturing process is key because even minor imperfections can lead to reduced capacity or cycle life. You also need to consider the importance of color stability in electrode materials, which impacts long-term performance and reliability. To optimize performance, manufacturers often incorporate surface treatments or doping techniques into electrode materials, which further improve conductivity and stability.

In essence, the development of electrode materials and the refinement of manufacturing processes are intertwined in creating effective hybrid lithium-ion capacitors. You benefit from advancements in material science that allow for electrodes with higher surface areas and better electrical conductivity. simultaneously, improved manufacturing methods ensure these materials are produced consistently and reliably at scale. Together, these factors enable hybrid lithium-ion capacitors to deliver high energy density alongside rapid charging capabilities, making them a versatile solution for future energy storage needs.

Frequently Asked Questions

How Do Hybrid Lithium-Ion Capacitors Compare Cost-Wise to Traditional Batteries?

You’ll find that hybrid lithium-ion capacitors generally have a higher cost comparison with conventional batteries due to their advanced materials and manufacturing expenses. While they offer better performance regarding power and energy, the complex manufacturing process increases costs. However, over time, their longer lifespan and superior efficiency can offset the initial expenses, making them a worthwhile investment for specific applications.

What Are the Environmental Impacts of Manufacturing and Disposing of These Capacitors?

You should know that manufacturing and disposing of hybrid lithium-ion capacitors pose environmental challenges. Recycling challenges arise because these capacitors contain toxic materials that require careful handling to prevent pollution. Disposal is risky due to potential toxic leaks that can harm ecosystems. To minimize impact, it’s vital to develop better recycling methods and safer materials, ensuring these devices are more sustainable throughout their lifecycle.

How Scalable Are Hybrid Lithium-Ion Capacitor Technologies for Large Energy Storage Systems?

You’ll find that hybrid lithium-ion capacitor technologies are quite scalable for large energy storage systems, but they face some scalability challenges. Manufacturing hurdles, like ensuring consistent quality and managing costs at scale, can slow progress. Despite these issues, ongoing research aims to improve production methods and materials, making it easier to deploy these capacitors widely. With continued advancements, you’ll see greater adoption in grid-scale and renewable energy storage applications.

What Are the Safety Concerns Associated With Hybrid Lithium-Ion Capacitors?

You should be aware that hybrid lithium-ion capacitors pose safety concerns like thermal runaway, which can cause fires or explosions if they overheat. Electrolyte leakage is another risk, potentially damaging the device and harming users. To mitigate these issues, manufacturers implement safety features such as thermal management systems and robust sealing. Regular monitoring and proper handling are essential to guarantee safe operation and prevent accidents.

How Do Temperature Variations Affect the Performance and Lifespan of These Devices?

Temperature variations can greatly impact your hybrid lithium-ion capacitors’ performance and lifespan. When temperatures fluctuate, it can compromise their thermal stability, leading to decreased efficiency. Repeated temperature cycling causes material stress, accelerating degradation and reducing lifespan. To maintain ideal performance, avoid exposing your device to extreme heat or cold, and store it in a stable environment. Proper thermal management ensures your capacitor remains reliable and lasts longer.

Conclusion

You see, hybrid lithium-ion capacitors blend power with energy, offering the best of both worlds. They deliver quick bursts of energy like traditional capacitors, yet store more energy like batteries. This balance means you get rapid response and longer-lasting performance. While they may not replace all energy storage needs, they certainly push the boundaries of what’s possible. In this fusion of speed and capacity, you find a promising future for energy storage—dynamic, efficient, and ready for tomorrow.