Reconditioning can typically restore between 50% and 80% of a battery’s original capacity, depending on its age and overall condition. If your battery has experienced moderate aging, you might see close to full capacity return. However, extensive deterioration usually limits how much improvement you can achieve. Understanding your battery’s history and health helps estimate potential gains. Keep exploring to discover detailed factors influencing reconditioning success and how you can maximize its benefits.

Key Takeaways

- Reconditioning can typically restore 50% to 80% of a battery’s original capacity.

- The extent of recovery depends on the battery’s age, usage history, and degree of deterioration.

- Moderate aging in newer batteries often yields closer to full capacity after reconditioning.

- Severe deterioration limits capacity restoration, making reconditioning less effective.

- Regular maintenance and proper usage can prolong the benefits of reconditioning over time.

Have you ever wondered how organizations determine when their operations will bounce back after a disruption? One key factor they consider is the condition of their batteries, especially in systems relying heavily on energy storage like backup power supplies, electric vehicles, or renewable energy setups. Battery aging is a natural process that occurs over time, causing batteries to lose capacity and efficiency. This aging results from chemical changes within the cells, leading to reduced runtime and performance. To assess whether a battery can be restored, organizations often turn to reconditioning techniques, which can sometimes extend a battery’s life considerably.

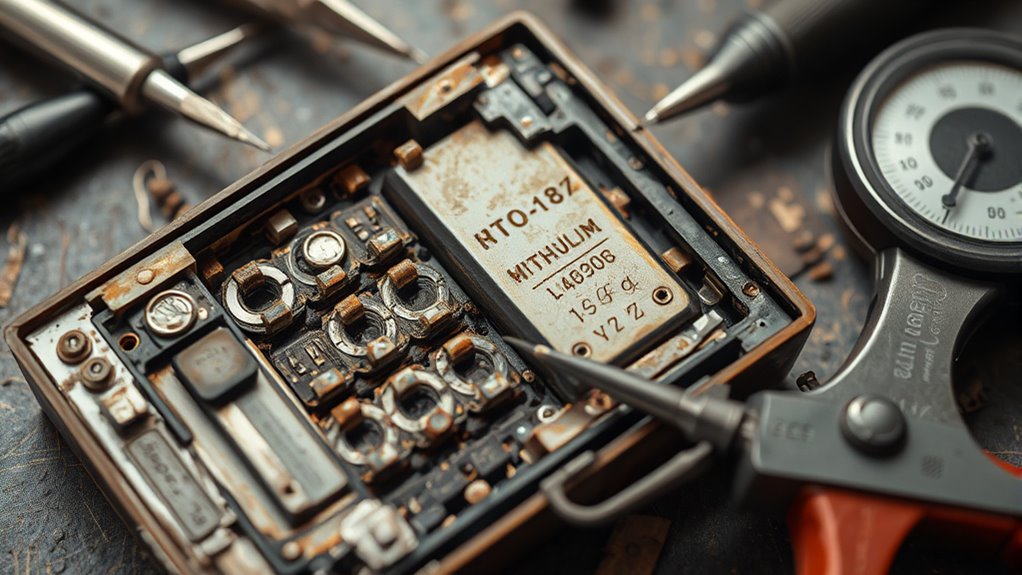

Reconditioning techniques involve a series of procedures designed to reverse some effects of battery aging. These methods can include deep cycling, which involves fully discharging and recharging the battery to recalibrate its capacity indicator, or applying controlled charging currents to break down crystalline formations that impair performance. In some cases, replacing or restoring electrolyte components can help revive a degraded battery. The goal of these techniques isn’t to make a battery as new but to restore enough capacity and efficiency for it to be useful again. This process can be a cost-effective alternative to outright replacement, especially when dealing with large-scale or vital systems.

Reconditioning techniques restore battery capacity through deep cycling and electrolyte adjustments, offering a cost-effective alternative to replacement.

When evaluating how much capacity can be recovered through reconditioning, you need to understand the extent of battery aging. As batteries age, their capacity diminishes, but the degree of loss varies depending on usage patterns, charging habits, and environmental conditions. Reconditioning can often recover 50% to 80% of a battery’s original capacity, depending on how severely it’s been affected. For example, a battery that’s only a few years old and has experienced moderate aging might bounce back close to its original capacity with proper reconditioning. However, if the battery has undergone extensive deterioration—say, due to deep discharges or high temperatures—the recovery might be limited. Additionally, advancements in battery technology can influence the effectiveness of reconditioning efforts.

It’s also vital to recognize that reconditioning isn’t permanent. The restored capacity may degrade again over time, especially if the underlying causes of aging aren’t addressed. Regular maintenance and proper usage can prolong the benefits gained from reconditioning. Ultimately, organizations rely on a combination of battery testing, understanding aging patterns, and applying suitable reconditioning techniques to estimate how much capacity can be restored and when replacement might become inevitable. This approach helps them plan operational timelines, optimize costs, and guarantee reliable performance in the face of unavoidable battery aging.

Frequently Asked Questions

How Do Temperature Variations Affect Capacity Recovery Estimates?

Temperature variations substantially impact capacity recovery estimates due to thermal effects and temperature cycling. When batteries experience fluctuating temperatures, their ability to recover diminishes because thermal stress accelerates degradation. Higher temperatures can temporarily boost capacity but cause long-term damage, while cold conditions slow chemical reactions, reducing efficiency. Accurately estimating recovery requires considering these thermal effects, as they influence how well a battery responds to reconditioning processes under different temperature cycling scenarios.

Can Reconditioning Fully Restore Battery Capacity to Original Levels?

They say “what’s lost is lost,” but reconditioning can considerably improve your battery’s lifespan. While it can restore some capacity degraded over time, it usually can’t bring it back to 100% of the original levels. Reconditioning helps reduce capacity degradation, extending your battery’s usefulness, but limitations exist. So, expect improvements, yet recognize that full restoration to factory capacity isn’t always achievable.

What Factors Influence the Success Rate of Capacity Restoration?

You can improve the success rate of capacity restoration by considering battery chemistry and charging protocols. Different chemistries, like lithium-ion or nickel-metal hydride, respond differently to reconditioning. Proper charging protocols, such as avoiding overcharging and using balanced charging, also boost effectiveness. You should verify that the reconditioning process aligns with the specific battery type and follows best practices to maximize potential recovery and longevity.

Are There Risks Associated With Aggressive Reconditioning Methods?

Jumping in with aggressive reconditioning can be a double-edged sword. While it might boost capacity quickly, it raises safety concerns, risking battery damage or failure. Plus, you could harm the environment through increased emissions or waste. Pushing too hard might seem tempting, but it’s wise to consider the potential gains against these risks. A cautious approach helps ensure safety and minimizes environmental impact, saving you trouble down the line.

How Long Do Restored Capacities Typically Last Before Declining Again?

Restored battery capacities usually last between several months to a couple of years, depending on usage and maintenance. You might notice some capacity fade over time, especially if you frequently charge and discharge the battery aggressively. To extend their lifespan, avoid deep discharges and keep the battery within ideal temperature ranges. Proper care helps delay capacity fade, ensuring your reconditioned battery performs well for as long as possible.

Conclusion

By understanding how much capacity can be reclaimed through reconditioning, you empower your equipment’s endurance and efficiency. Recognize the real potential beneath the worn surface and witness the wondrous ways reconditioning restores, revitalizes, and renews. With careful calibration and committed care, you can confidently convert costly replacements into cost-effective corrections. Remember, every effort to restore is a step toward sustainable systems, strengthening your success story with seamless, sustainable solutions.