Solid-state batteries replace liquid electrolytes with solid materials, offering higher energy, faster charging, and improved safety. They work by allowing ions to move through solid electrolytes, which are more stable and less prone to issues like dendrite formation. While promising, challenges remain in manufacturing, material stability, and scalability, meaning they are not yet widely available. If you keep exploring, you’ll discover more about how these exciting innovations could soon transform energy storage and electric vehicles.

Key Takeaways

- Solid-state batteries replace liquid electrolytes with solid materials, increasing energy density and safety.

- They work by allowing lithium ions to move through solid electrolytes between electrodes.

- Current challenges include ensuring electrolyte stability and manufacturing scalable, defect-free layers.

- Advances in materials science and fabrication techniques are critical for commercial viability.

- Widespread adoption is expected within the next 5-10 years, promising faster charging and longer-lasting EV batteries.

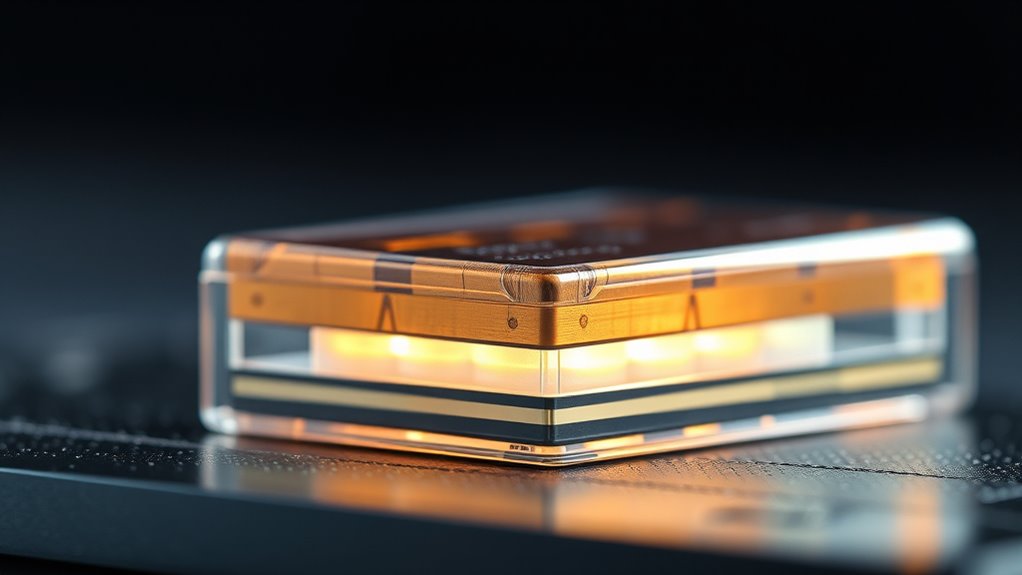

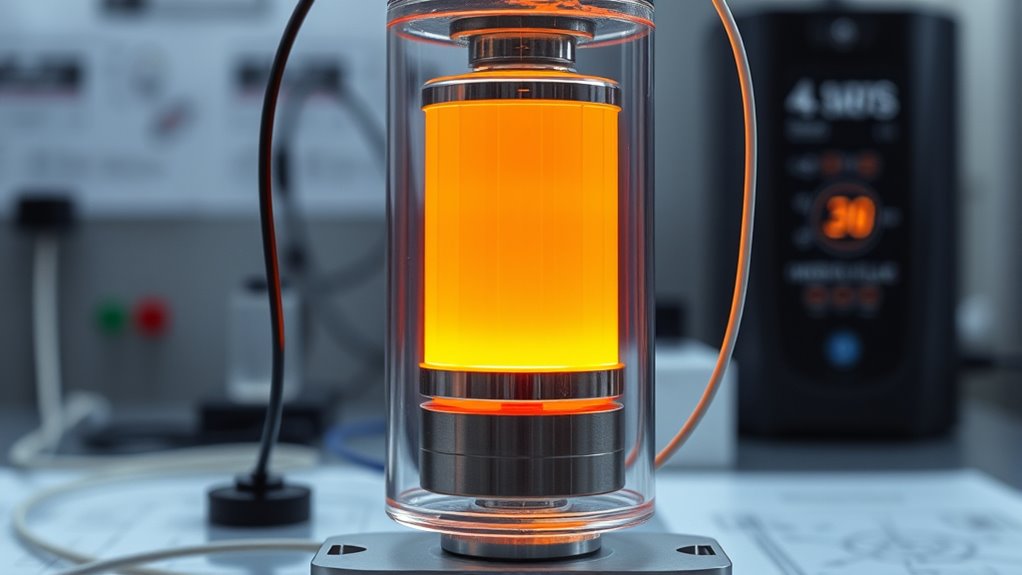

Have you ever wondered how future electric vehicles might achieve faster charging and longer ranges? Solid-state batteries are often hailed as the key to releasing this potential. Unlike traditional lithium-ion batteries that use liquid electrolytes, solid-state batteries replace these with solid electrolytes. This shift offers numerous advantages, but it also comes with significant hurdles. One of the main challenges is electrolyte stability. The solid electrolytes need to maintain their integrity over many charge cycles, resisting dendrite formation and degradation that can cause safety issues or reduce performance. Achieving a stable electrolyte that can conduct ions efficiently while remaining durable over time is vital. Researchers are exploring various materials, such as ceramics and sulfides, but each has its own set of stability concerns. For instance, some ceramic electrolytes are highly stable but brittle, making them difficult to manufacture into thin, uniform layers. Others may conduct ions well but are sensitive to moisture or temperature variations, which can compromise stability. Overcoming these issues is paramount for solid-state batteries to reach commercial viability.

Another major obstacle lies in manufacturing challenges. Producing solid electrolytes at scale requires precise control over material quality and layer uniformity, which is difficult with current methods. The manufacturing process must guarantee that the solid electrolyte forms a seamless interface with both the anode and cathode, minimizing contact resistance and preventing the formation of voids or cracks. Such defects can severely impair battery performance and safety. Additionally, integrating solid electrolytes into battery cells involves adapting existing production lines or developing entirely new processes, both of which are costly and complex. Achieving consistent, high-quality production while keeping costs manageable is essential for mass-market adoption. Researchers and manufacturers are actively working on advanced fabrication techniques, such as thin-film deposition and sheet lamination, but these methods are still in developmental stages. Until these manufacturing challenges are addressed, widespread commercial deployment of solid-state batteries remains limited.

Despite these hurdles, the potential benefits of solid-state batteries make them a highly promising technology. They promise higher energy density, faster charging times, improved safety, and longer lifespans. As scientists continue to improve electrolyte stability and refine manufacturing processes, you can expect to see solid-state batteries gradually making their way into electric vehicles and portable devices. When these challenges are finally overcome, they could revolutionize energy storage, enabling electric vehicles to charge in minutes and travel hundreds of miles on a single charge. For now, the journey is ongoing, but the future of solid-state batteries looks bright and full of possibilities. Advances in material science are crucial for overcoming current limitations and unlocking their full potential.

Frequently Asked Questions

How Do Solid-State Batteries Compare to Traditional Lithium-Ion Batteries in Cost?

You’ll find that solid-state batteries currently cost more than traditional lithium-ion batteries due to higher manufacturing expenses. The cost comparison shows that solid-state technology involves advanced materials and precise production processes, which drive up prices. While they promise better safety and performance, it’s likely to take time before costs drop and become more competitive with lithium-ion batteries as manufacturing scales up and technology advances.

What Are the Main Challenges in Scaling up Solid-State Battery Production?

You face significant manufacturing hurdles when scaling up solid-state battery production. Material scalability is a primary challenge, as producing large quantities of high-quality, defect-free solid electrolytes proves difficult. Additionally, maintaining consistent quality during mass manufacturing requires advanced techniques and substantial investment. Overcoming these obstacles involves developing cost-effective, scalable methods and improving material stability, so you can bring solid-state batteries to market more efficiently and meet increasing demand.

How Long Will Solid-State Batteries Last in Everyday Use?

Battery balance boosts longevity, but you should expect solid-state batteries to last around 10 to 20 years with proper care. They typically resist degradation mechanisms better than traditional lithium-ion batteries, thanks to stable solid electrolytes. However, factors like temperature, charge cycles, and usage habits can influence their lifespan. So, while they promise longer-lasting performance, your routine will still play a crucial role in maximizing their durability.

Are There Safety Concerns Specific to Solid-State Battery Technology?

You might wonder if solid-state batteries pose safety concerns. Generally, they offer improved fire risk and thermal stability compared to traditional lithium-ion batteries, making them safer. However, like any technology, they can still experience issues if damaged or improperly manufactured. You should handle them carefully, avoid punctures, and guarantee quality manufacturing. Overall, solid-state batteries are safer but still require cautious use to prevent potential safety risks.

When Can Consumers Expect to See Solid-State Batteries in Commercial Products?

You can expect to see solid-state batteries in commercial products within the next 3 to 5 years. Consumer adoption will accelerate as manufacturers achieve regulatory approval and address production challenges. Once these batteries meet safety standards and become cost-effective, expect to see them in electric vehicles, smartphones, and portable electronics. Keep an eye on industry progress, as advancements will determine how quickly they reach your devices.

Conclusion

Solid-state batteries are like the dawn of a new era, promising brighter days for electric vehicles and portable gadgets. They’re the sturdy bridge to faster charging, longer ranges, and safer rides, all while waving goodbye to the old battery blues. Though they’re still on the horizon, their arrival will feel like finally opening the perfect gift—powerful, reliable, and ready to transform your world. Get ready, because the future of energy is charging up faster than ever.