To recondition lead-acid batteries safely, start by wearing protective gear and working in a well-ventilated area. Carefully disconnect and drain the old electrolyte, inspecting for cracks or damage. Refill the cells with a suitable mixture and allow the battery to sit before slowly charging it. Throughout, handle acids carefully and dispose of waste properly. If you keep going, you’ll discover detailed steps to restore your battery effectively and safely.

Key Takeaways

- Wear protective gear and work in a well-ventilated area to prevent acid exposure and gas accumulation during reconditioning.

- Disconnect the battery, open vents, and inspect for damage before draining old electrolyte safely.

- Replenish electrolyte with distilled water and Epsom salt or a reconditioning solution, then allow it to settle overnight.

- Charge the battery slowly with monitoring tools, ensuring electrolyte levels are even and no irregularities occur.

- Dispose of old electrolyte responsibly according to hazardous waste regulations and store or recycle the battery properly.

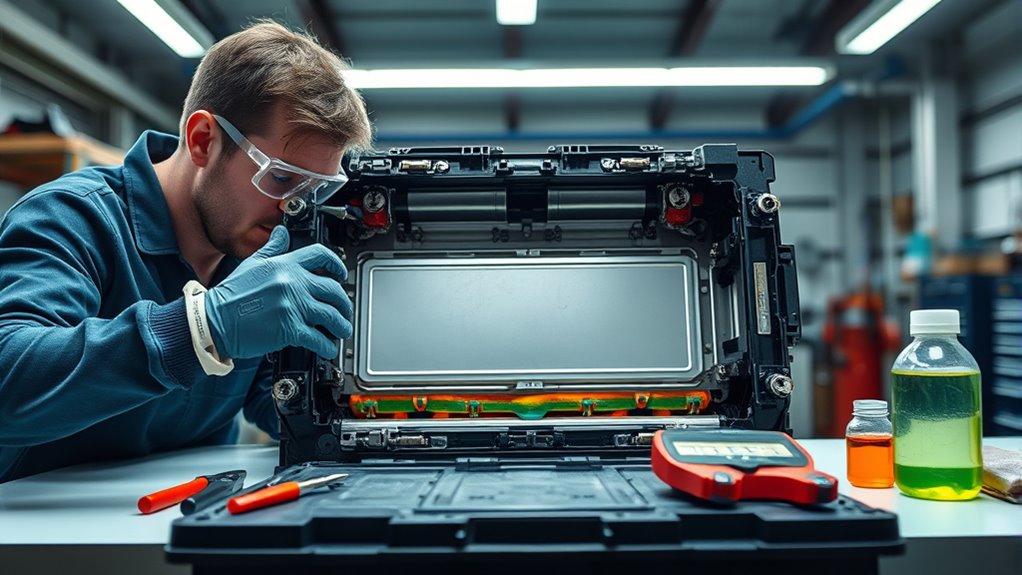

Reconditioning lead-acid batteries is a practical way to extend their lifespan and save money. When you’re considering this process, understanding battery chemistry is vital. Lead-acid batteries operate through a chemical reaction between lead plates and sulfuric acid, which creates electrical energy. Over time, the active materials on the plates can become sulfated or lose their capacity, reducing the battery’s efficiency. Reconditioning restores some of this lost capacity by removing sulfate buildup and balancing the electrolyte. However, before you begin, it’s essential to prioritize safety precautions to protect yourself from potential hazards. Acid spills, hydrogen gas release, and electrical shocks are real risks, so wearing protective gear like gloves, goggles, and an apron is non-negotiable. Make sure you work in a well-ventilated area to disperse any hydrogen gas that may accumulate during the process. Keep a fire extinguisher nearby, just in case, and ensure your tools and workspace are free of sparks or open flames.

Once you’re prepared, start by disconnecting the battery and removing it from any vehicle or device. Carefully open the vents or caps on the battery to access the electrolyte. Before proceeding, inspect the battery for cracks or leaks—if you notice any, it’s best to replace the battery instead of reconditioning it. Next, use a hydrometer to check the specific gravity of the electrolyte; this measurement indicates the state of charge and helps you determine if reconditioning is necessary. To recondition, you typically drain the old electrolyte into a suitable container—never discard it casually, as sulfuric acid is hazardous. You can then rinse the battery plates with distilled water, being cautious to avoid spilling acid. Replenish the electrolyte with a specially formulated lead-acid battery reconditioning solution or a mix of distilled water and a small amount of Epsom salt, which can help break down sulfate deposits. Incorporating automated insights can help monitor the reconditioning process and ensure optimal results.

Throughout this process, always remember your safety precautions. Handle acids carefully, avoid inhaling fumes, and dispose of old electrolyte according to local hazardous waste regulations. After refilling the battery with the new electrolyte, allow it to sit for several hours or overnight, ensuring the electrolyte settles evenly. Charge the battery slowly and monitor it closely for any irregularities. By following these steps precisely and respecting safety guidelines, you give your lead-acid battery a new lease on life, saving money while promoting safe handling practices.

Frequently Asked Questions

Can Reconditioning Extend a Battery’s Lifespan Indefinitely?

Reconditioning can substantially extend your battery’s lifespan, but it won’t make it last indefinitely. It helps restore battery capacity and can delay replacement, giving you more use out of it. However, over time, chemical wear and age will still reduce its effectiveness. So, while reconditioning is a great way to prolong your battery’s lifespan, expecting it to last forever isn’t realistic. Regular maintenance is key for peak performance.

What Are the Signs a Lead-Acid Battery Needs Reconditioning?

Your battery’s warning signs are like a dimming light—reduced battery capacity, sluggish performance, and frequent need for recharging. Check electrolyte levels; if they’re low or uneven, it’s time for reconditioning. You might notice swelling or corrosion as well. These signs indicate your lead-acid battery needs a boost to restore its health and performance, helping it shine brightly once more.

How Do Temperature Changes Affect the Reconditioning Process?

Temperature changes can profoundly impact your reconditioning process. You should maintain temperature stability, as fluctuations cause thermal impact that can damage the battery’s internal components. Cold temperatures slow chemical reactions, making reconditioning less effective, while excessive heat accelerates degradation. Always perform reconditioning in a controlled environment, avoiding extreme temperatures to ensure safety and maximize the battery’s recovery potential. Proper temperature management helps you achieve better, safer results.

Is Reconditioning Suitable for All Types of Lead-Acid Batteries?

Reconditioning isn’t suitable for all lead-acid batteries because Battery chemistry and size vary. You should assess whether your battery is flooded, AGM, or gel, as each reacts differently to reconditioning. Larger batteries may require more careful handling and specific techniques, while smaller ones are easier to recondition safely. Always verify compatibility to prevent damage or safety risks, and consult manufacturer guidelines or a professional if unsure.

What Safety Precautions Are Essential During Reconditioning?

During reconditioning, you should always wear personal protective equipment like gloves and goggles to protect yourself from acid splashes. Verify proper ventilation in your workspace to avoid inhaling harmful fumes. Handle batteries carefully, avoid sparks, and work in a well-ventilated area. Always follow safety guidelines, keep a fire extinguisher nearby, and dispose of acids properly to prevent accidents and health hazards.

Conclusion

By following these steps, you’ll breathe new life into aging lead-acid batteries, turning them from worn-out husks into vibrant power sources. With patience and careful attention, you’ll navigate the process like a skilled navigator steering through rough waters, transforming a tired, dead battery into a shining example of your resourcefulness. Reconditioning not only saves money but also helps you harness the power of renewal—proving that even the most tired batteries can be reborn with a little effort.