Solid-state batteries replace liquid electrolytes with solid materials, which efficiently conduct ions between electrodes. This shift improves safety by reducing risks of leaks, fires, or thermal runaway. They also offer higher energy density, more durability, and longer lifespan, making them ideal for electric vehicles and portable devices. Although manufacturing challenges exist, ongoing research is advancing their stability and performance. To understand how these innovations could transform energy storage, discover the key details behind their design and benefits.

Key Takeaways

- Solid electrolytes conduct ions efficiently between electrodes, replacing liquid electrolytes for enhanced safety and stability.

- They enable safer batteries with reduced risk of leakage, evaporation, and thermal runaway.

- Solid-state batteries offer higher energy density and longer lifespan compared to traditional liquid electrolyte batteries.

- Manufacturing challenges include ensuring uniform interfaces and material stability, which are crucial for performance.

- These batteries are promising for electric vehicles, electronics, and energy storage due to their durability and safety features.

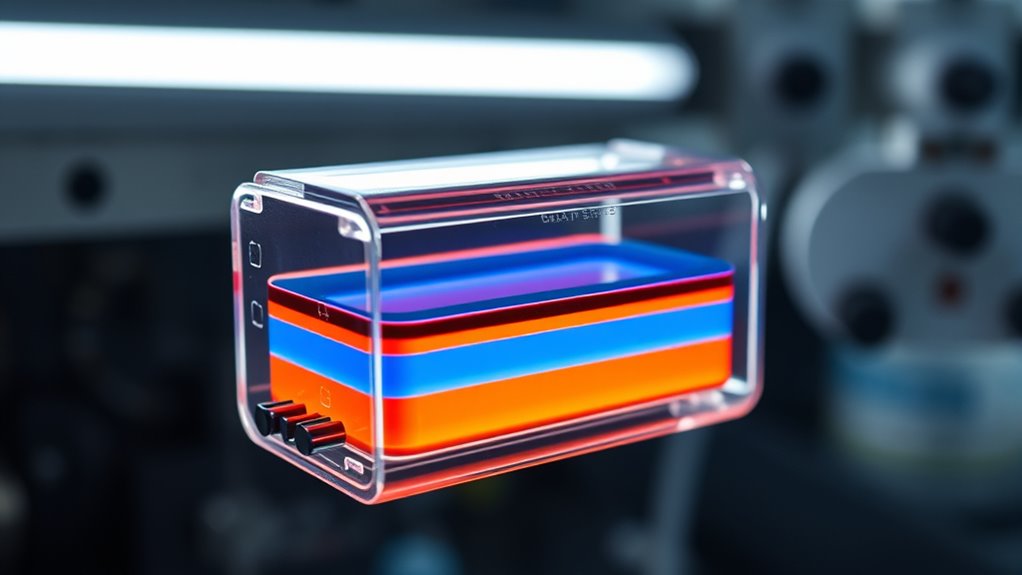

Solid-state batteries are an innovative type of energy storage technology that use solid electrolytes instead of the liquid or gel electrolytes found in traditional lithium-ion batteries. This shift offers several advantages, but it also introduces specific challenges you need to understand. One of the key factors in the effectiveness of solid-state batteries is electrolyte stability. Unlike liquid electrolytes, which can be prone to leakage, evaporation, or decomposition over time, solid electrolytes are generally more stable under a wide range of temperatures and conditions. This stability reduces the risk of thermal runaway, making the batteries safer and more durable. However, achieving consistent electrolyte stability isn’t straightforward. Researchers must carefully select materials that can conduct ions efficiently while maintaining stability over many charge and discharge cycles. The challenge lies in finding a solid electrolyte that combines high ionic conductivity with long-term stability without degrading or reacting with other battery components.

On top of electrolyte stability, manufacturing challenges markedly impact the development and deployment of solid-state batteries. Producing solid electrolytes on a large scale can be difficult because the materials often require precise processing conditions, such as controlled atmospheres and high temperatures. These requirements increase production complexity and cost. Additionally, creating a uniform interface between the solid electrolyte and the electrodes is vital for performance but difficult to achieve consistently. Imperfections or gaps at these interfaces can hinder ion flow, reduce efficiency, and lead to early failure. Scaling up manufacturing processes from laboratory settings to industrial levels presents further hurdles, as maintaining quality and performance across mass-produced units becomes increasingly complex. This makes the shift from prototype to commercial product slower and more expensive. Moreover, advances in manufacturing techniques are essential to overcome these barriers and enable widespread adoption.

Despite these manufacturing challenges, the potential benefits of solid-state batteries are notable. Their enhanced safety profile, higher energy density, and longer lifespan make them attractive for electric vehicles, portable electronics, and energy storage systems. You’ll find that ongoing research aims to develop new materials and fabrication techniques to overcome current limitations. Innovations such as ceramic electrolytes, polymer composites, and novel interface engineering strategies are promising steps forward. While the journey to widespread adoption involves addressing electrolyte stability and manufacturing challenges, the improvements solid-state batteries offer in terms of safety, capacity, and longevity make them a compelling future energy solution. As technology advances, you can expect these hurdles to gradually diminish, paving the way for more reliable, efficient, and safer energy storage options.

Frequently Asked Questions

How Long Do Solid-State Batteries Typically Last?

Solid-state batteries typically last around 10 to 15 years or between 1,000 to 2,000 charge cycles, depending on usage and degradation factors. You can expect a longer battery lifespan compared to traditional lithium-ion batteries due to reduced degradation. Proper handling, avoiding extreme temperatures, and minimizing deep discharges help maintain their performance over time, ensuring you get the most out of your solid-state battery’s longevity.

Are Solid-State Batteries Safe in Extreme Temperatures?

Your solid-state batteries are remarkably resilient, capable of withstanding extreme temperatures better than traditional batteries. Thanks to their superior thermal stability and temperature resilience, they remain safe even in harsh conditions, avoiding the risks of overheating or freezing. While no battery is completely invincible, solid-state technology offers a level of safety and durability that makes them a dependable choice for extreme environments.

What Are the Main Challenges in Mass Production?

You’ll face scalability hurdles and manufacturing complexities when trying to mass-produce solid-state batteries. These challenges include developing cost-effective production processes, ensuring consistent quality, and managing the delicate handling of advanced materials. Overcoming these obstacles requires innovative engineering and significant investment. As a result, large-scale manufacturing remains difficult, but advances in technology and increased industry focus are gradually making it more feasible to produce solid-state batteries efficiently and at scale.

How Do Costs Compare to Traditional Lithium-Ion Batteries?

You’ll find that solid-state batteries currently have higher manufacturing expenses than traditional lithium-ion batteries, leading to a steeper cost comparison. While the technology promises benefits like increased safety and energy density, the production process is more complex and expensive. As manufacturing advances and scales up, costs are expected to decrease, making solid-state batteries more competitive. For now, their higher price tag reflects the current state of development and manufacturing challenges.

Can Solid-State Batteries Be Recycled Easily?

Yes, solid-state batteries can be recycled, but the process is still developing. Recycling processes for these batteries involve separating components like the solid electrolytes and electrodes, which can be more complex than traditional lithium-ion batteries. While recycling helps reduce environmental impact, current methods need refinement to improve efficiency and cost-effectiveness. As technology advances, you’ll find solid-state batteries becoming easier and more sustainable to recycle, benefiting both the environment and industry.

Conclusion

Imagine a future powered by solid-state batteries—safer, more efficient, and ready to revolutionize your world. As they replace traditional batteries, you’ll experience faster charging, longer-lasting devices, and enhanced safety. It’s like upgrading from a candle to a lighthouse—guiding us toward innovation and sustainability. Embrace this leap forward, because the power to transform your everyday life is already within reach. Solid-state batteries aren’t just the future; they’re the spark igniting it.