To float bulk materials quickly, you need to understand buoyancy, which depends on the density difference between the material and the liquid. First, measure the mass and volume of your material to find its density. If the material is less dense than the liquid, it will float; if more, it sinks. You can tweak conditions, like adding agents or adjusting the liquid’s density, to speed up separation in under 10 minutes. Keep going to learn more about mastering this simple technique.

Key Takeaways

- The float method uses buoyancy principles to quickly separate liquids from bulk materials within 10 minutes.

- Calculating material and liquid density predicts whether items will float or sink.

- Adding buoyant agents or adjusting liquid density enhances floatation efficiency.

- Proper measurement and comparison of densities enable rapid separation by float or sink behavior.

- Understanding these fundamentals allows fast, reliable bulk liquid removal in industrial processes.

If you need to quickly remove excess liquids from bulk materials, mastering the bulk absorption float technique can save you time and effort. This method hinges on understanding how materials behave when immersed in liquids, which involves principles like buoyancy and density calculation. Knowing these concepts allows you to manipulate the process efficiently, ensuring rapid and effective liquid removal.

Master the bulk absorption float technique for quick, efficient removal of excess liquids from bulk materials.

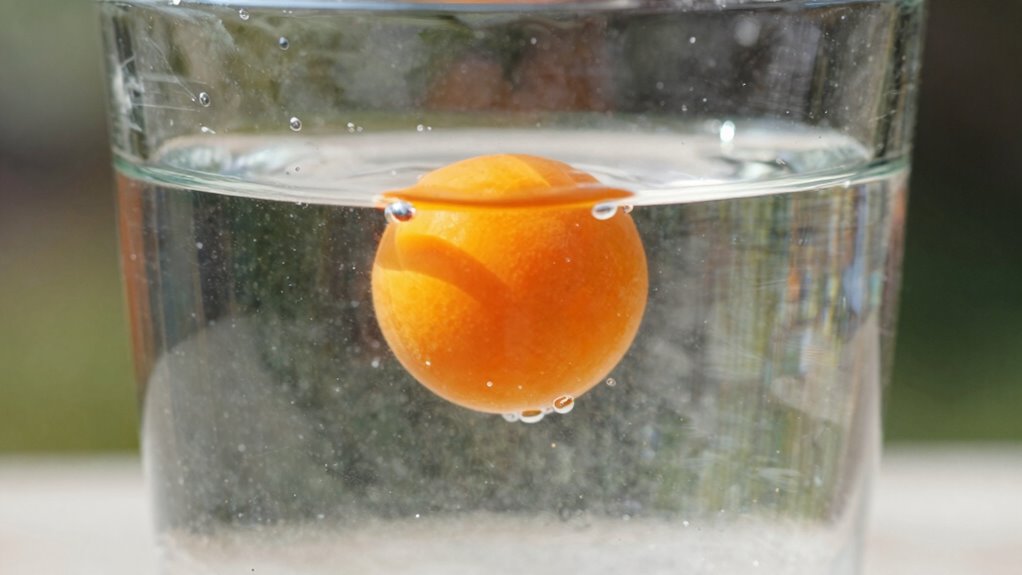

At its core, the float technique works because of buoyancy principles, which state that an object submerged in a fluid experiences an upward force equal to the weight of the displaced fluid. When you add bulk materials to a liquid, their ability to float or sink depends primarily on their density relative to the liquid. To determine whether your material will float, you need to perform a density calculation. By dividing the mass of your material by its volume, you get its density. If this density is less than that of the liquid, the material will float; if it’s higher, it will sink.

To apply this in practice, start by accurately measuring the mass of your bulk material and the volume it occupies. Once you have these measurements, calculate the density by dividing the mass by the volume. Knowing the density of your material and the liquid allows you to predict whether it will float or sink. This understanding is essential because it guides your next steps—whether you need to modify the material, adjust the liquid’s density, or use specific techniques to enhance floatation.

The key to speeding up the process lies in manipulating the buoyancy principles. For instance, if your material sinks, you might add a buoyant agent or alter the liquid’s properties (like increasing its density) so that your material becomes less dense in comparison. Conversely, if the material floats easily, you can quickly skim or separate the floating bulk. The idea is to capitalize on the natural buoyant behavior by adjusting conditions to make the separation almost automatic.

This process is not just about trial and error; it’s about applying scientific principles straightforwardly. By understanding the density calculation and buoyancy principles, you’re equipped to optimize the absorption float method. With practice, you’ll be able to determine the best adjustments in seconds, reducing the time needed to clear excess liquids from large quantities of materials. Mastering these fundamentals makes the bulk absorption float technique a quick, dependable solution for efficiently managing liquids in industrial or processing settings, often in less than ten minutes. Additionally, understanding the contrast ratio helps in assessing how well your setup will visually perform during the separation process.

Frequently Asked Questions

How Does Bulk Absorption Differ From Other Absorption Methods?

Bulk absorption differs from other absorption methods because it involves the entire volume of a material taking in liquids through adsorption mechanisms. Unlike surface adsorption, where only the surface captures substances, bulk absorption integrates the liquid throughout the material. Material differences, such as porosity and structure, determine how effectively it absorbs. You’ll notice that bulk absorption is faster and holds more liquid because it relies on the whole material, not just its surface.

Can Floatation Be Used for All Types of Liquids?

Floatation isn’t suitable for all liquids, like trying to fit a square peg in a round hole. You need to contemplate liquid compatibility because some liquids may dissolve or damage the floatation material. Limitations arise when the liquid’s properties, such as viscosity or chemical composition, interfere with floatation’s effectiveness. Always check these factors first, or you might find your floatation method sinking faster than you’d like.

What Are the Safety Precautions for Quick Absorption Processes?

You should always wear personal protective equipment like gloves and goggles to prevent skin and eye contact during quick absorption processes. Make sure spill containment measures are in place, such as absorbent mats or barriers, to control any accidental leaks. Follow proper procedures for handling and disposal, and keep a first aid kit nearby. These precautions help guarantee your safety while efficiently managing rapid absorption activities.

How Accurate Is the 10-Minute Absorption Method?

You might worry about the 10-minute absorption method’s accuracy, but it’s generally reliable for quick assessments. While individual absorption rates vary, the measurement accuracy is close enough for practical purposes, especially if you follow the procedure carefully. Keep in mind, factors like temperature or sample size can influence results, so consider it a helpful estimate rather than an exact measurement.

Are There Environmental Impacts of Using Bulk Absorption Techniques?

Using bulk absorption techniques can have environmental consequences, such as potential ecological effects from chemical runoff or improper disposal. You might inadvertently introduce pollutants into water sources, harming aquatic life or disrupting ecosystems. To minimize these impacts, guarantee proper handling, disposal, and use environmentally friendly materials whenever possible. Being mindful of these ecological effects helps protect the environment while benefiting from the efficiency of bulk absorption methods.

Conclusion

Now you’re all set to master bulk absorption float in just ten minutes. Think of it like riding a bicycle—once you get the hang of it, it’s second nature. Remember, patience and practice are your best allies; like a knight in shining armor, you’ll conquer the technique in no time. So go ahead, give it a whirl, and soon you’ll be floating effortlessly. Trust me, even a modern-day Robin Hood would be proud of your skills!