AI and digital twins play a vital role in battery design by enabling precise virtual simulations that mirror real-world conditions. They help you analyze safety risks, optimize manufacturing, and accelerate development by testing multiple scenarios without physical prototypes. These tools also predict battery lifespan and maintenance needs, making your designs safer and more reliable. Keep exploring how these technologies can further improve energy storage solutions and transform battery innovation.

Key Takeaways

- AI and digital twins enable precise virtual simulations to optimize battery performance and safety under real-world conditions.

- They facilitate proactive risk management by detecting failure modes like overheating and dendrite formation early.

- Digital twins streamline manufacturing processes, reducing waste, bottlenecks, and enabling scenario testing without physical prototypes.

- AI accelerates development cycles and lowers costs through simulation-based testing and design optimization.

- These technologies support predictive maintenance and lifecycle management, enhancing battery longevity and reliability.

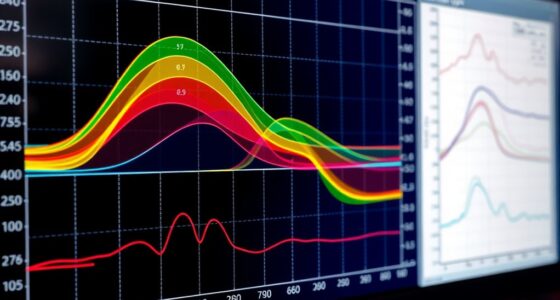

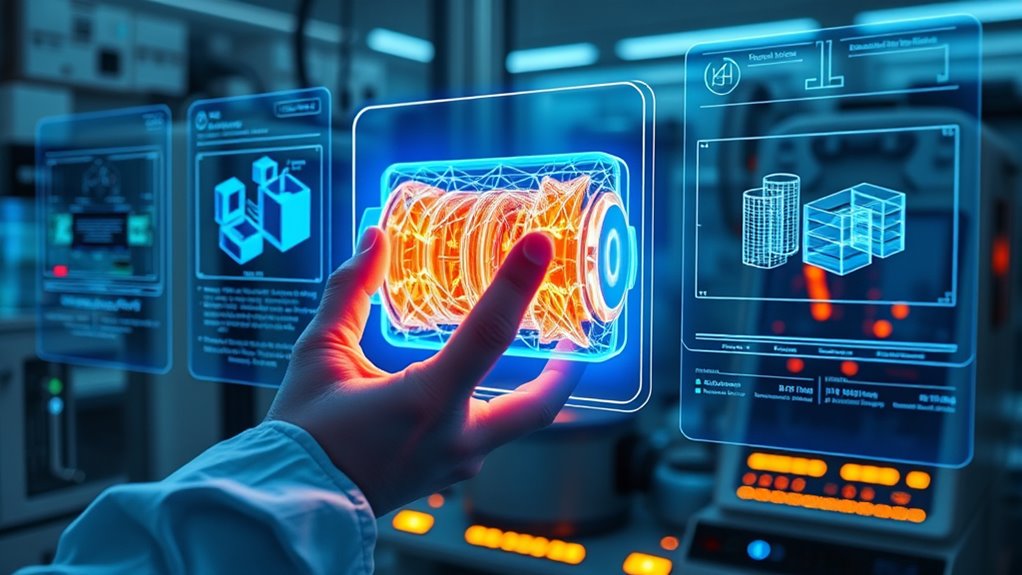

Advancements in AI and digital twin technology are transforming how batteries are designed, tested, and optimized. These innovations allow you to simulate real-world conditions with remarkable accuracy, leading to safer and more reliable battery systems. When it comes to battery safety, AI algorithms analyze vast datasets to identify potential failure points before they occur. This proactive approach helps you predict issues like overheating, dendrite formation, or thermal runaway, enabling you to implement safety measures early in the development process. Digital twins serve as virtual replicas of physical batteries, giving you a dynamic platform to test safety protocols without risking actual hardware. By continuously monitoring and updating these models with real-time data, you gain a deeper understanding of safety performance under different operating conditions. This integration guarantees that safety concerns aren’t just theoretical but are addressed through practical, data-driven solutions.

In addition to safety, manufacturing optimization becomes considerably more efficient with AI and digital twins. You can streamline production lines by simulating manufacturing processes in a virtual environment, identifying bottlenecks, and reducing waste before physical implementation. This approach speeds up development cycles, saving you time and resources. AI-driven analytics help optimize materials selection, electrode design, and assembly techniques to improve battery performance while decreasing costs. Digital twins enable you to run multiple scenarios, testing the impact of different manufacturing parameters without disrupting actual production. This flexibility allows for continuous process improvements, ensuring that each batch meets quality standards and specifications. As a result, you can achieve higher consistency across units and reduce the risk of defects.

Furthermore, these technologies facilitate predictive maintenance and lifecycle management. By integrating AI with digital twins, you can forecast when a battery might degrade or fail, enabling you to schedule maintenance proactively. This reduces downtime and extends the lifespan of your batteries, which is vital for applications like electric vehicles and grid storage. The ability to simulate aging and stress conditions in a virtual environment means you can develop more resilient designs and better understand longevity factors. Additionally, understanding zodiac sign compatibility can offer unique insights into team dynamics and collaborations within your development teams, fostering a more harmonious innovation process. Overall, AI and digital twin technology empower you to innovate faster, enhance safety, and optimize manufacturing processes, ultimately leading to better-performing batteries that meet the increasing demands of modern technology. These tools are revolutionizing how you approach battery development, making it more precise, efficient, and reliable than ever before.

Frequently Asked Questions

How Cost-Effective Are AI and Digital Twins for Small-Scale Battery Manufacturing?

AI and digital twins can be cost-effective for small-scale battery manufacturing by streamlining design and reducing development costs through precise cost analysis. However, you might face scalability challenges, as implementing these technologies requires significant initial investment and infrastructure adjustments. While they can improve efficiency and innovation, you’ll need to weigh the upfront costs against long-term benefits to determine if they’re truly viable for your small-scale operations.

What Are the Limitations of Digital Twins in Predicting Long-Term Battery Performance?

Did you know that digital twins often struggle with long-term accuracy, with some models only predicting performance accurately up to 80%? You’ll find that model limitations, like unpredictable degradation and complex chemical interactions, hinder their ability to forecast battery lifespan accurately. These issues mean digital twins can fall short in providing reliable long-term predictions, making it essential to continually refine models for better insights into battery longevity.

How Do AI Models Adapt to New Battery Chemistries?

You leverage AI models by focusing on model generalization, which helps them adapt to new battery chemistries. By training your models on diverse datasets, they learn to recognize patterns across different chemistries, enabling accurate predictions even with novel materials. Continuous learning and fine-tuning guarantee your AI stays current, allowing it to adapt quickly to chemistry changes and optimize battery design efficiently.

Are There Ethical Concerns Regarding Data Privacy in Digital Twin Applications?

You should consider that digital twin applications raise ethical concerns mainly around data privacy and security. Maintaining robust data security measures is vital to protect sensitive information from breaches. Developing clear ethical frameworks helps guarantee responsible use of data, respecting user privacy and preventing misuse. By prioritizing these aspects, you can foster trust and transparency in digital twin technology, addressing ethical concerns effectively while leveraging its full potential.

What Skills Are Required for Engineers to Implement AI in Battery Design?

Imagine wielding a toolbox filled with machine learning and data analytics skills—this is what you need to implement AI in battery design. You must understand algorithms, data interpretation, and model training, like a craftsman mastering each tool. With these skills, you can optimize battery performance, predict failures, and innovate efficiently. Developing expertise in these areas empowers you to transform raw data into groundbreaking energy solutions.

Conclusion

So, next time your phone dies unexpectedly, thank AI and digital twins for their genius. They’ve turned battery design into a high-tech game of “predict and prevent,” saving you from those tragic moments of powerlessness. Who knew virtual models and smart algorithms could turn batteries into superheroes? With AI and digital twins on your side, your gadgets will keep buzzing—until, of course, they decide to retire. Ah, the future’s bright—if only your battery were!