Recombinant lead‑acid batteries, or VRLA batteries, are designed to safely contain gases produced during charging by allowing them to be recombined into water inside a sealed case. This process reduces water loss and maintenance, making the batteries safer and more durable. You’ll find these batteries commonly used for backup power and renewable energy systems. As you explore further, you’ll discover how their innovative design improves efficiency and environmental sustainability.

Key Takeaways

- VRLA batteries use sealed designs to prevent electrolyte spillage and gas escape during operation.

- They generate hydrogen and oxygen gases during charging, which are recombined inside the sealed container.

- Gas recombination converts gases back into water, reducing water loss and maintenance needs.

- The valve-regulated system enhances safety, efficiency, and extends battery lifespan.

- These batteries are environmentally friendly, easier to recycle, and suitable for backup and renewable energy applications.

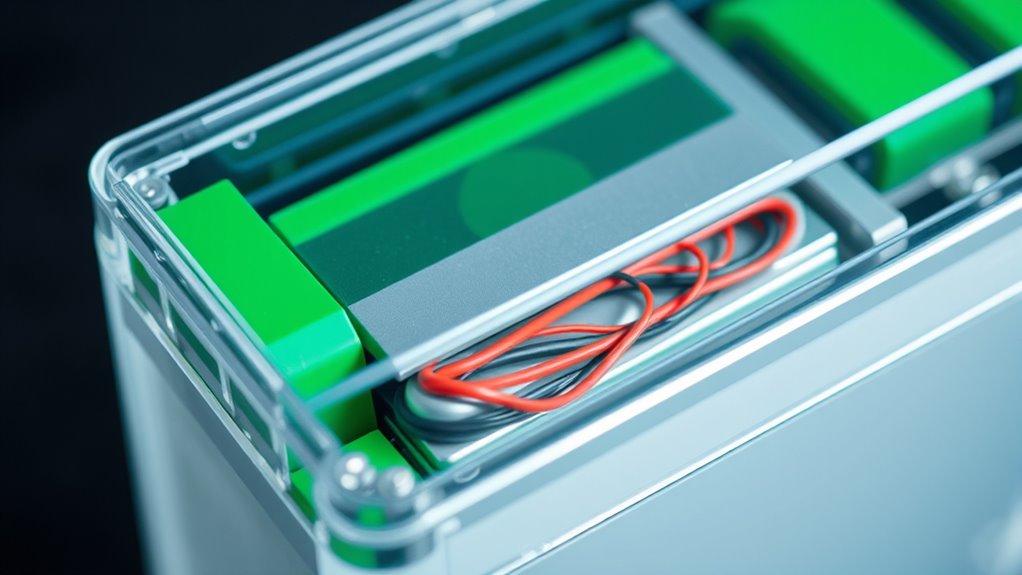

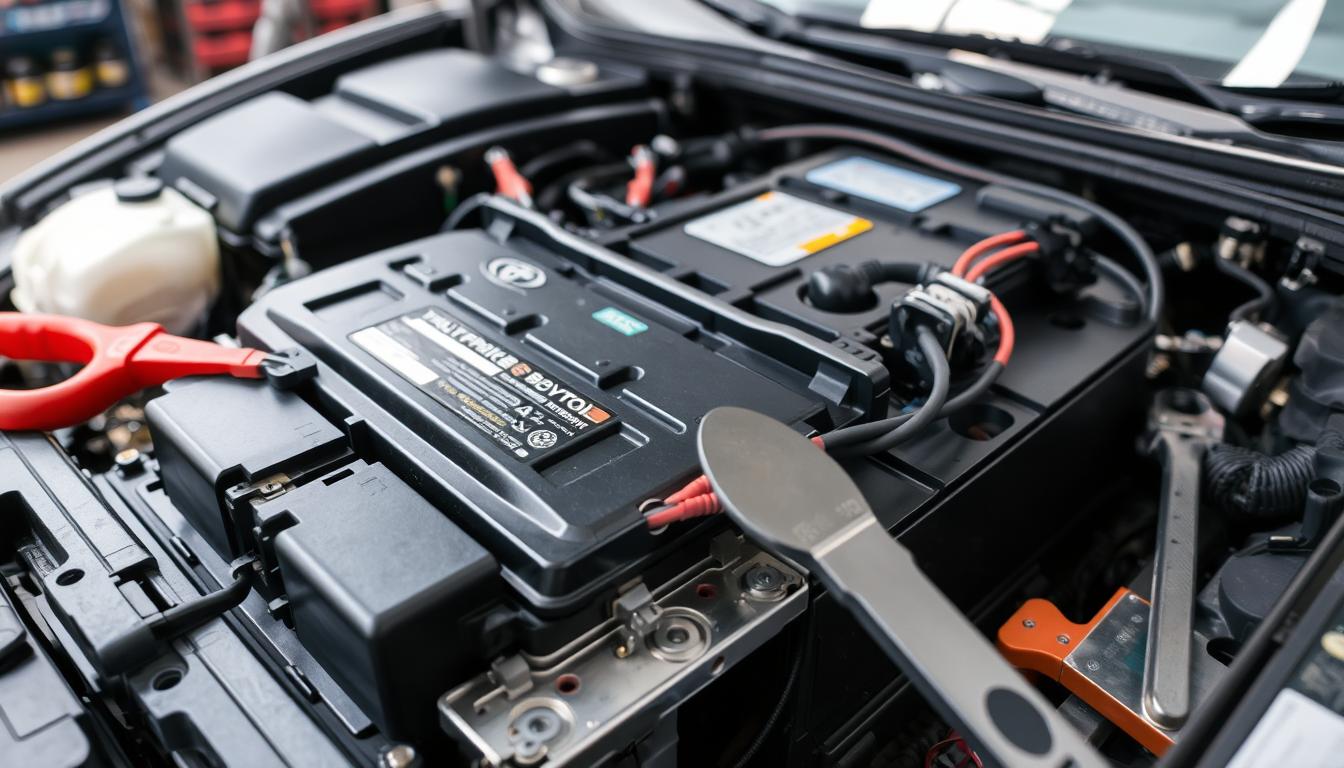

Recombinant lead-acid batteries represent a notable advancement in energy storage technology by allowing the gases produced during charging to be recombined into water within the battery, reducing maintenance and water loss. This innovative design, known as valve-regulated lead-acid (VRLA), enhances the safety, efficiency, and longevity of traditional lead-acid batteries. When you consider the manufacturing of these batteries, you’ll find that the process involves carefully sealed components to prevent electrolyte spillage and minimize gas escape. This sealing not only improves safety but also simplifies maintenance, making VRLA batteries ideal for a wide range of applications from backup power to renewable energy systems.

In the manufacturing phase, quality control is critical to ensure the recombination process functions effectively. The batteries are constructed with lead plates immersed in a sulfuric acid electrolyte, but what sets VRLA apart is the inclusion of a valve that regulates gas release. During charging, the lead plates generate hydrogen and oxygen gases, but instead of escaping into the environment, these gases are directed through a recombination mechanism within the sealed container. The hydrogen and oxygen recombine into water, which is then absorbed back into the electrolyte. This process considerably reduces water consumption, meaning you won’t need to top up the electrolyte as often, and it extends the overall lifespan of the battery. Additionally, the sealed design helps prevent gas escape, which contributes to safer operation.

Recycling processes for VRLA batteries are also streamlined because of their sealed design and durable construction. When these batteries reach the end of their life, you can recycle them more efficiently compared to traditional flooded lead-acid batteries. The sealed design minimizes spillage and environmental contamination, making it easier and safer to handle during recycling. You’ll find that recycling involves extracting the lead, plastic, and other materials, which can then be processed and reused in new battery manufacturing. Proper recycling is essential not only for environmental sustainability but also for conserving valuable resources, reducing the need for raw material extraction, and lowering the overall environmental footprint of battery production.

Frequently Asked Questions

How Do Recombinant Lead-Acid Batteries Compare to Traditional Flooded Types?

You’ll find recombinant lead-acid batteries superior to traditional flooded types because of their recombinant plate design and electrolyte recombination process. These features enable them to recombine gases internally, reducing water loss and maintenance needs. Unlike flooded batteries, VRLA batteries are sealed, making them safer and more reliable for various applications. They also deliver consistent performance, longer lifespan, and better resistance to vibration and temperature changes.

What Are the Environmental Impacts of VRLA Battery Manufacturing?

You should know that VRLA battery manufacturing impacts the environment through manufacturing emissions, releasing pollutants during production. Recycling challenges also exist because lead and acid components need careful handling to prevent contamination. While these batteries are more eco-friendly than traditional types, reducing emissions and improving recycling processes are essential to lessen environmental harm and promote sustainability in VRLA battery production.

Can VRLA Batteries Be Recycled Easily?

Think of VRLA batteries like a puzzle you can piece back together; yes, they can be recycled. Recycling processes efficiently recover lead and plastics, making reuse straightforward. Environmental regulations ensure proper handling, minimizing hazards. You might be surprised—over 99% of lead from these batteries is recyclable, reducing waste and environmental impact. So, with proper procedures, VRLA batteries are not only recyclable but also a sustainable choice.

How Does Temperature Affect VRLA Battery Performance?

You’ll notice that temperature critically impacts VRLA battery performance. Higher temperatures can diminish temperature stability, causing faster electrolyte evaporation and potential damage, while lower temperatures may decrease capacity and efficiency. Proper thermal management is essential; it helps maintain ideal operating conditions, prolongs battery life, and ensures reliable performance. By controlling temperature, you prevent overheating or freezing, ensuring your VRLA battery functions efficiently and safely over its lifespan.

What Are Common Troubleshooting Steps for VRLA Battery Failure?

When troubleshooting VRLA battery failure, start by checking the battery capacity to see if it meets your system’s needs. Inspect electrolyte management for signs of leakage or dryout, which can cause failure. Make certain proper ventilation and temperature control, as high or fluctuating temperatures impact performance. Test connections and look for corrosion or swelling. Regular maintenance and monitoring help prevent issues and prolong your VRLA battery’s life.

Conclusion

In conclusion, recombinant lead-acid batteries revolutionize reliability with their robust, reengineered design. By harnessing hydrogen and oxygen, they humbly hold high, helping you harness harnessed energy efficiently. This sustainable, sealed solution simplifies storage, safeguards your system, and sustains your success. Therefore, select smarter, safer, and stronger storage with recombinant lead-acid batteries—your reliable, renewable, and risk-reduced power partner for the future.