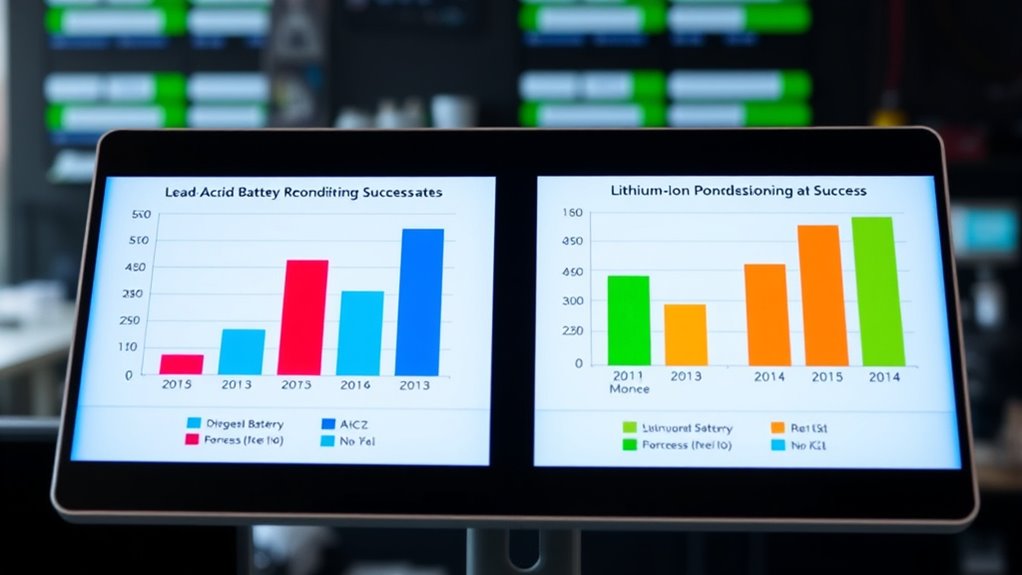

Reconditioning success rates differ particularly between lead-acid and lithium-ion batteries. Lead-acid batteries often respond well, especially if they’re relatively new and haven’t been deeply discharged, with many batteries regaining significant capacity after reconditioning. Lithium-ion batteries, however, typically have lower success rates due to their limited charge cycles and complex chemistry. The age, condition, and number of cycles impact your chances of success. Keep exploring to learn more about maximizing your reconditioning efforts.

Key Takeaways

- Lead-acid batteries generally have higher reconditioning success rates due to their ability to recover capacity through multiple charge cycles.

- Lithium-ion batteries have limited reconditioning potential because they undergo fewer cycles before capacity decline, reducing success rates.

- The age and prior condition of the battery significantly influence reconditioning outcomes for both types.

- Proper safety protocols are essential, especially for lead-acid batteries, to prevent hazards during reconditioning.

- Overall success rates are higher for lead-acid batteries, but advanced techniques and careful handling can improve lithium-ion reconditioning results.

Battery reconditioning has become a popular way to extend the lifespan of old batteries, but success rates can vary widely depending on several factors. When you’re working on reconditioning lead-acid or lithium-ion batteries, understanding how charge cycles impact the process is essential. Each charge cycle—where a battery is charged and then discharged—gradually wears down the cells, reducing capacity over time. Reconditioning aims to reverse some of this wear, but its effectiveness depends on the battery’s age and condition. For lead-acid batteries, multiple charge cycles can sometimes restore a significant portion of their original capacity, especially if the battery hasn’t been deeply discharged or damaged. Lithium-ion batteries, however, tend to have fewer charge cycles before their performance drops, making reconditioning more challenging but still possible in some cases.

Safety protocols play an important role in ensuring your success and protecting you from potential hazards. Lead-acid batteries contain sulfuric acid and can emit explosive gases during charging, so proper ventilation and protective gear are non-negotiable. You should always wear gloves and goggles, work in a well-ventilated area, and handle batteries carefully to avoid spills or leaks. Lithium-ion batteries are less hazardous in terms of corrosive fluids but pose significant risks of thermal runaway or fire if mishandled or punctured. Always follow manufacturer instructions and safety guidelines, and never attempt to recondition a damaged or swollen battery. Proper safety protocols minimize risks and increase your chances of successful reconditioning. Additionally, understanding the AI security implications of handling advanced battery technologies can help prevent potential safety and cybersecurity issues associated with modern battery management systems.

Frequently Asked Questions

How Long Does the Reconditioning Process Typically Take?

The reconditioning process usually takes between 1 to 3 hours, depending on the battery type and condition. Your reconditioning timeline varies based on factors like the battery’s age and whether you’re working with lead-acid or lithium-ion cells. During this process, you’ll notice the recharge duration shortens as the battery regains capacity. Make sure to follow proper procedures to make certain of safety and achieve the best results within this typical timeframe.

Are There Safety Risks Involved With Reconditioning Either Battery Type?

Think of reconditioning batteries like handling delicate glassware—you need careful safety protocols to avoid accidents. Both lead-acid and lithium-ion batteries pose risks, such as leaks or fires if mishandled. Following proper hazard mitigation steps, like wearing protective gear and working in ventilated areas, minimizes dangers. While risks exist, adhering to safety measures guarantees you can recondition batteries safely and successfully.

What Tools Are Necessary for Successful Reconditioning?

To successfully recondition batteries, you need essential tools like charging equipment and safety gear. Charging equipment helps restore the battery’s capacity, while safety gear such as gloves and goggles safeguards you from potential hazards like acid leaks or sparks. Make sure your tools are compatible with the specific battery type you’re working on. Always prioritize safety and follow proper procedures to ensure effective and safe reconditioning.

How Often Can Lead-Acid Batteries Be Reconditioned?

You can recondition lead-acid batteries up to three or four times, extending their lifespan considerably. Remarkably, proper recycling methods and reconditioning can recover around 70% of their original capacity. Each reconditioning cycle helps you maximize battery life and reduces waste. Keep in mind, however, that after multiple cycles, performance may decline, so monitor your battery’s condition closely to ensure safe and effective use.

Does Reconditioning Affect Battery Warranty Coverage?

Reconditioning your battery can affect warranty coverage, as it may void manufacturer policies if done improperly or without approval. Always check warranty implications before attempting reconditioning, since manufacturers often specify what repairs or modifications are covered. If you follow proper procedures and document your work, you might avoid voiding the warranty. However, it’s safest to consult your manufacturer to understand specific policies and avoid potential issues.

Conclusion

When comparing lead-acid and lithium-ion batteries, you’ll find that reconditioning success rates differ markedly. Surprisingly, lead-acid batteries boast a success rate of up to 80%, making them more recoverable than lithium-ion options, which hover around 50%. This means you have a better shot at extending the life of lead-acid batteries, saving you money and reducing waste. Ultimately, understanding these stats helps you make smarter choices for your battery maintenance and environmental impact.