Battery reconditioning can be safe for beginners if you understand the risks and follow proper safety protocols. Handle hazardous materials with caution, wearing gloves, goggles, and protective clothing. Make sure your workspace is well-ventilated and keep necessary safety equipment nearby. Avoid reconditioning damaged or leaking batteries, and always disconnect batteries carefully. If you keep these safety tips in mind, you’ll reduce hazards while reconditioning. For detailed guidance, understanding the key precautions will help you get started confidently.

Key Takeaways

- Proper safety equipment like gloves and goggles is essential to protect beginners from chemical exposure and hazards.

- Understanding battery chemistry helps identify specific risks and appropriate safety precautions for different battery types.

- Handling damaged or leaking batteries increases the risk of chemical burns or fires, so beginners should inspect batteries carefully.

- Working in a well-ventilated area and following safety protocols reduces exposure to toxic fumes and minimizes accident risks.

- Educating oneself through resources and manufacturer guidelines is crucial for safe reconditioning practices, especially for beginners.

If you’re considering reconditioning batteries, safety should always come first. This process involves working with potentially hazardous materials, and understanding the risks is essential to protect yourself and others. Before diving into reconditioning, you need to familiarize yourself with the different battery chemistry you’ll encounter. For example, lead-acid batteries, lithium-ion packs, and nickel-metal hydride cells each have unique properties and risks. Lead-acid batteries, common in cars, contain sulfuric acid, which can cause severe burns if spilled. Lithium-ion batteries, found in many electronic devices, pose fire hazards if damaged or improperly handled. Identifying the specific chemistry helps you know what precautions to take and what safety equipment you’ll need.

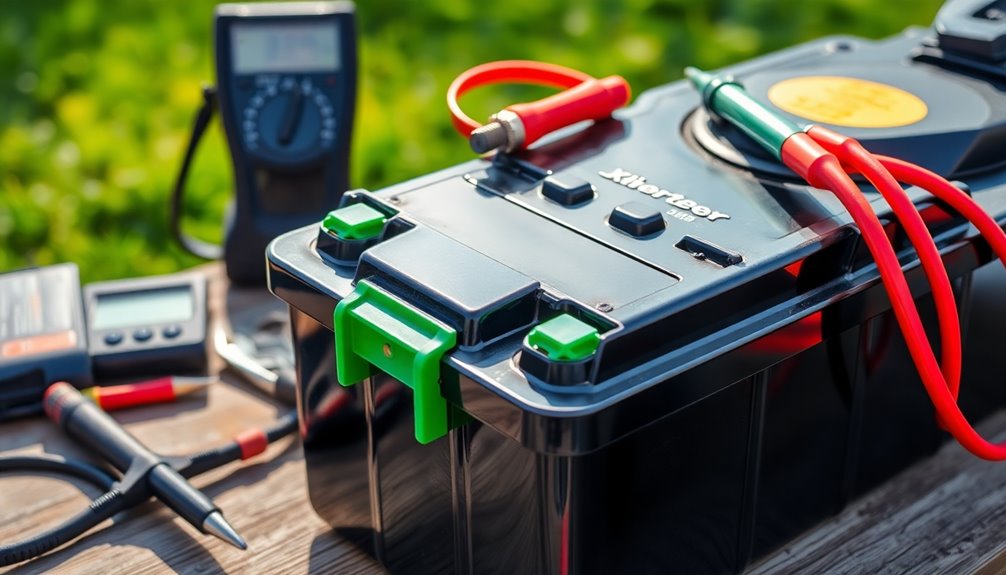

Using the right safety equipment is critical when reconditioning batteries. Gloves, goggles, and protective clothing are your first line of defense against corrosive acids, harmful fumes, and accidental sparks. Gloves made from rubber or latex prevent chemical burns, while goggles shield your eyes from splashes or debris. A well-ventilated workspace is also crucial because some batteries emit toxic gases during the process. A face mask or respirator adds extra protection against inhaling dangerous fumes, especially when working with sealed or damaged batteries. Remember, safety gear isn’t optional; it’s your best safeguard against injuries and health issues.

Wearing gloves, goggles, and protective gear is essential to stay safe when reconditioning batteries.

Handling batteries improperly can lead to serious safety risks. Always disconnect batteries carefully, avoiding sparks or static electricity, which can ignite flammable gases released during reconditioning. Make sure you work on a stable, non-conductive surface, and keep a fire extinguisher nearby, just in case. When working with older or damaged batteries, inspect them for leaks, cracks, or bulges. If you notice any signs of damage, it’s safer to dispose of the battery properly rather than attempt reconditioning. Also, never attempt to recondition a battery if you’re unsure about its condition or if you lack the proper training. Following manufacturer guidelines and safety protocols minimizes accidents and ensures you’re working within safe limits.

Additionally, staying informed about resources and tools available for battery reconditioning can help you better understand the proper procedures and safety measures. Following manufacturer guidelines and safety protocols minimizes accidents and ensures you’re working within safe limits. With careful preparation and awareness, you can reduce hazards and successfully recondition batteries without putting yourself in harm’s way. Remember, safety isn’t just a step—it’s the foundation of any successful and responsible reconditioning project.

Frequently Asked Questions

Can Battery Reconditioning Cause Electrical Shocks?

Yes, battery reconditioning can cause electrical shocks if you’re not careful. Electrical hazards are a real concern, especially when handling batteries or working with charged components. To prevent shocks, always wear insulated gloves and use proper tools. Shock prevention measures are essential, so never work on a battery when it’s still connected or if you’re unsure of your safety. Stay cautious and follow safety guidelines to avoid dangerous electrical shocks.

What Are the Legal Restrictions on Reconditioning Batteries?

You need to know that legal restrictions on reconditioning batteries are strict and can feel like steering through a maze. Ensuring legal compliance is essential because liability considerations could turn a minor mistake into a major legal headache. Some regions ban certain types of reconditioning or require special permits, so you must research local laws thoroughly. Ignoring these rules risks hefty fines or legal action, so stay informed and always follow regulations carefully.

Do All Types of Batteries Pose the Same Safety Risks?

No, not all batteries pose the same safety risks because battery chemistry varies. For example, lithium-ion batteries can be more volatile than lead-acid ones. When reconditioning, you should always use proper safety equipment like gloves and goggles to protect yourself from potential hazards such as acid spills or explosions. Understanding the specific safety precautions for each battery type helps you avoid accidents and guarantees a safer reconditioning process.

Is Professional Training Necessary to Recondition Batteries Safely?

You don’t need professional training to recondition batteries safely, but understanding battery safety is vital. Training importance lies in teaching you proper handling, safety precautions, and troubleshooting techniques, reducing risks like sparks or chemical leaks. With proper knowledge, you can confidently recondition batteries, but always follow safety guidelines. If you’re unsure, seeking expert advice or formal training can help guarantee you avoid accidents and maintain safe practices throughout the process.

How Can Beginners Minimize the Risk of Battery Explosions?

Imagine sparks flying as you work on a recharged battery—scary, right? To minimize explosion risks, always wear safety gear like goggles and gloves, and guarantee proper ventilation in your workspace. Keep a fire extinguisher nearby, work slowly, and avoid overcharging. These precautions create a safer environment, helping you handle batteries confidently while reducing the chance of dangerous accidents. Safety first keeps your reconditioning journey smooth and secure.

Conclusion

So, is battery reconditioning safe for beginners? With proper precautions and thorough knowledge, you can minimize risks and enjoy the process. However, always respect the potential dangers involved and don’t rush into things without understanding the basics. Are you willing to prioritize safety and learn responsibly? Remember, patience and preparation are key to avoiding accidents. If you stay cautious, you can confidently recondition batteries and save money without compromising your safety.