Reconditioning a car battery usually takes several hours to a couple of days, depending on the type of battery and its condition. For lead-acid batteries, the full process, which includes desulfation and equalization charging, might stretch up to 36 hours. If you're working with lithium-ion batteries, expect similar timeframes. Remember, older or damaged batteries often require multiple cycles for effective restoration. It's important to properly assess and maintain your battery for optimal results. Want to know more about the reconditioning process and what tools you'll need? Keep exploring for useful insights!

Key Takeaways

- Car battery reconditioning typically takes several hours to a few days, depending on the battery type and condition.

- Lead-acid batteries require around 36 hours for a full recharge during the reconditioning process.

- Lithium-ion batteries may have similar timeframes but can vary based on cell balancing needs.

- Full reconditioning may take up to 12 hours for certain battery types, especially if multiple cycles are needed.

- Regular assessment and monitoring can help determine the specific reconditioning time required for each battery.

Understanding Car Battery Reconditioning Time

Understanding car battery reconditioning time is essential for anyone looking to extend their battery's lifespan. Different battery types require distinct reconditioning methods, which directly impacts the time you'll spend.

For instance, lead-acid batteries often need desulfation and equalization charging, taking around 36 hours for a full recharge. In contrast, lithium-ion batteries involve balancing cells and generally require a similar timeframe for reconditioning but can vary based on their specific condition. Additionally, full reconditioning can take up to 12 hours for certain battery types, highlighting the variability in the process.

The entire reconditioning process can span from several hours to a few days, depending on the battery's type and state. If your battery's been in long-term storage, you might need multiple cycles to restore its functionality.

Start with a visual inspection for any physical damage, then use a desulfator for lead-acid types, or balance cells for lithium-ion batteries.

After reconditioning, always test the battery with a voltmeter to ensure it's functioning properly. A reading around 12.42V for lead-acid batteries indicates a good state.

Ultimately, understanding these reconditioning times helps you plan effectively and maintain your battery's performance over time.

Safety Precautions for Reconditioning

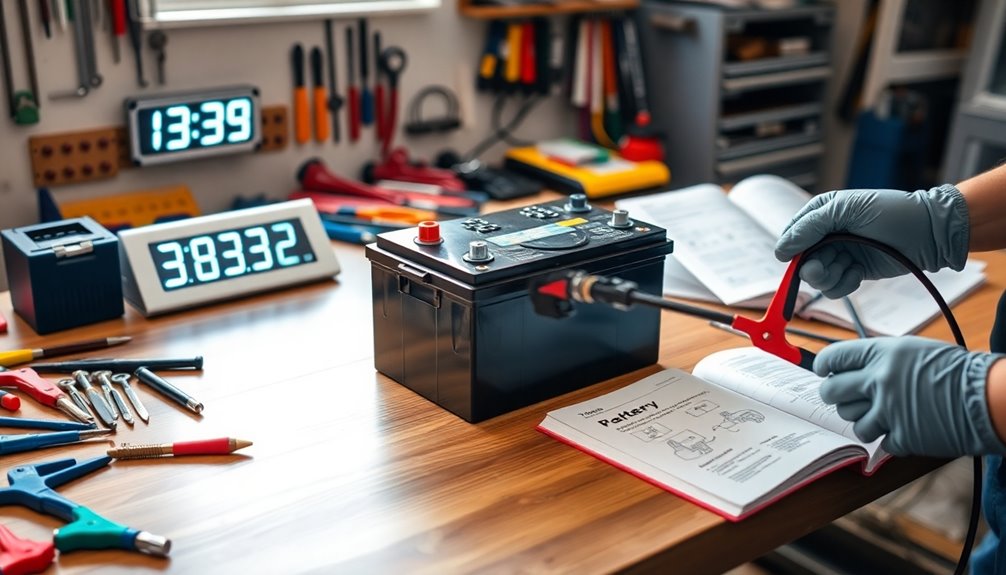

When reconditioning a car battery, prioritizing safety is crucial to prevent accidents and injuries. Start by wearing approved safety glasses or goggles and consider using a face shield to protect your eyes from potential acid splashes.

Chemical-resistant gloves are essential to guard against acid spills, so make sure to wear them along with thick clothing to shield your body. Proper knowledge of battery functionality enhances maintenance practices and informs users about when reconditioning is required.

Ensure your workspace is well-ventilated to avoid inhaling harmful gases. Keep the area free from cigarettes, flames, and sparks, as these can ignite fumes.

Never lean over the battery while boosting, testing, or charging, and keep metallic tools away to prevent short circuits.

Handle sulfuric acid with caution, and if you get any on your skin, flush the area with water immediately. Neutralize any battery acid with baking soda before disposal and use distilled water to maintain electrolyte levels in flooded lead-acid batteries.

Always consult the vehicle and battery owner's manuals for specific safety instructions, and follow the manufacturer's guidelines for all tools.

Regularly test voltage and performance to identify any critical issues, and avoid overcharging to prevent overheating.

Steps for Effective Reconditioning

Reconditioning a car battery involves several crucial steps to restore its functionality effectively.

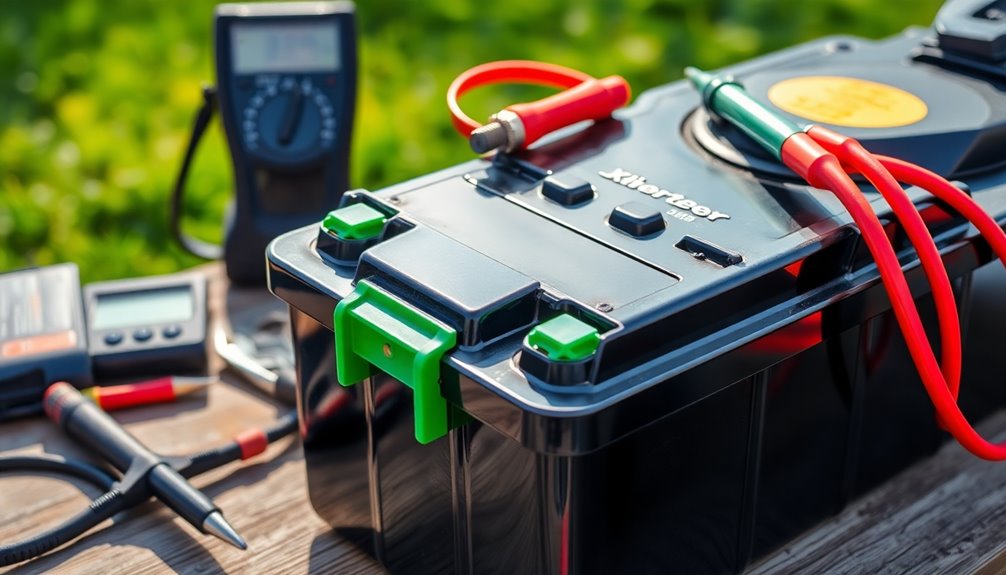

Start by checking and preparing the battery. Use a multimeter to measure the voltage of each cell; it should be between 10V and 12.6V for reconditioning. Make sure there are no physical damages, then detach the battery cables, beginning with the negative terminal.

Next, clean and desulfate the battery. Create a paste using baking soda and water, apply it to corroded terminals, and scrub with a toothbrush or steel wool. This process helps to remove sulfate crystal build-up that can hinder performance.

Empty the battery cells, neutralize the acid, and refill them with a cleaning solution. Shake the battery to distribute the solution, then dispose of it safely.

Now, replace the electrolyte and recharge the battery. Mix 4 cups of water with 4 ounces of Epsom salt and refill the cells with this new solution.

Recharge the battery at 12V / 2 amps for 36 hours, monitoring it closely.

Finally, test and evaluate the battery. Reinstall it, check the voltage under load, and make sure it doesn't drop below 9.6V. If it does, repeat the charging and testing process.

Tools and Equipment Needed

Proper tools and equipment are essential for successful car battery reconditioning. First, prioritize your safety. Make sure you have safety goggles, chemical-resistant gloves, and an apron to protect your skin and eyes.

Working in a well-ventilated area will help minimize exposure to harmful fumes.

For cleaning and maintenance, you'll need a toothbrush, steel wool or a battery terminal cleaner, and a flathead screwdriver. A funnel and a baking soda and water mixture will serve as an effective cleaning paste to remove corrosion.

Invest in specialized battery service tools to ensure accurate testing and charging. A battery terminal tester and a battery charger are crucial, along with a battery maintainer or float charger and a battery load tester to assess the battery's health.

If you're diving into advanced reconditioning, gather a voltmeter with probes to measure voltage levels, a battery post cleaner with wire brushes, and an adjustable torque drill for connecting cables. Additionally, if you are working with hybrid batteries, a cooling box and compatible cooling fan become necessary.

With the right tools and equipment, you'll be well-equipped for successful battery reconditioning.

Maintenance Tips for Longevity

To keep your car battery running strong for years, consistent maintenance is key. Start by regularly cleaning the battery terminals to prevent corrosion.

Mix baking soda and water in a 2:1 ratio, apply it to the terminals, and scrub gently with a toothbrush or steel wool. Rinse with warm water and dry thoroughly. Make sure to inspect the terminals frequently for any signs of corrosion.

When charging, use a trickle charger for 12-24 hours and apply an equalization charge to balance cell voltages. Avoid deep discharging; keep the battery voltage above 12 volts whenever possible. Battery reconditioning can significantly help enhance the battery's performance and extend its lifespan.

Cycling charge and discharge a few times can help restore capacity. Be mindful of environmental factors too. Keep your battery away from extreme temperatures and limit short trips that prevent full charging.

Regularly check the electrolyte levels in flooded lead-acid batteries, adding distilled water as needed.

Finally, perform regular testing with a voltmeter to monitor voltage levels. A normal reading should be around 12.42V.

Keep a record of all maintenance activities to track the battery's condition and ensure longevity.

Signs Your Battery Needs Reconditioning

Car batteries can show several signs that they need reconditioning, and recognizing these indicators early can save you from being stranded.

If you notice reduced run time or your vehicle runs out of power more quickly than usual, it's a clear sign. Slow charging and frequent jump starts also indicate underlying issues. If your engine takes longer to turn over, it suggests insufficient battery power. Regular checks are recommended for older batteries to ensure they are still functioning effectively.

Keep an eye out for visible signs too. A swollen battery case or any bad smell, often from sulfuric acid, points to a dying battery. Corrosion on the terminals can interfere with electrical connections, while any physical damage like swelling or leaking needs immediate attention.

You might also experience electrical and starting issues. Difficulty starting in the morning or unusual whining noises from the engine can signal problems. Flickering dashboard lights or your engine shutting down shortly after starting indicate a failing battery.

Lastly, if your battery is old or shows low voltage, reconditioning is likely necessary. Regular maintenance can help you catch these signs early and extend the life of your battery.

Frequently Asked Questions

Can I Recondition Any Type of Car Battery?

You can recondition several types of car batteries, including lead-acid, nickel-cadmium, and nickel-metal hydride.

Lithium-ion batteries can also be reconditioned, but they require specialized knowledge.

However, not every battery is suitable for reconditioning; damaged ones or those with severe issues may not be restorable.

Always assess the battery's condition and age first, and ensure you're using the right tools and safety precautions before starting the reconditioning process.

Is Reconditioning Safe for Old Batteries?

Reconditioning old batteries can be safe if you follow proper precautions.

Always wear chemical-resistant gloves, safety goggles, and ensure your workspace is well-ventilated. Keep tools away from terminals to avoid short circuits and check battery voltage with a multimeter before starting.

However, be cautious; improper techniques can damage the battery or create hazards. If a battery's voltage is below 10V, it's usually better to replace it instead of attempting reconditioning.

How Often Should I Recondition My Battery?

You should recondition your battery based on its usage and age.

If you drive infrequently, consider reconditioning it more often, especially if it's over three years old.

Keep an eye out for signs like slower charging or reduced runtime, which indicate it's time for maintenance.

For newer batteries, you mightn't need to do it as frequently.

Regularly check the voltage to ensure it's within the safe range for reconditioning.

What Costs Are Associated With Battery Reconditioning?

When considering battery reconditioning, you'll face costs typically ranging from $1,000 to $2,500.

This varies based on your battery type and the extent of work needed. The expertise of the service provider plays a role too.

While it's generally cheaper than buying a new battery, you should factor in additional expenses like labor and materials.

Always compare price estimates from different providers to ensure you're getting the best deal possible.

Will Reconditioning Completely Restore Battery Performance?

Reconditioning can significantly improve your battery's performance, but it won't completely restore it to like-new condition.

You might see a restoration of up to 80% of its original capacity, especially with lead-acid batteries.

However, if your battery is heavily damaged or corroded, reconditioning likely won't work as well.

It's essential to assess its condition first, as success hinges on how well the battery has been maintained over time.

Conclusion

In conclusion, reconditioning your car battery can take anywhere from a few hours to a couple of days, depending on the method you choose. Always prioritize safety and follow the steps carefully for the best results. By using the right tools and maintaining your battery properly, you can extend its life significantly. Keep an eye out for signs that your battery needs reconditioning, and you'll ensure your vehicle stays reliable for the road ahead.