Charging reconditioned batteries involves techniques like desulfation and cycle charging to restore their capacity. You should use the right charger, ensuring it's compatible with your battery type. Always check your connections for quality and maintain proper safety precautions, like ventilation and using protective gear. Monitor voltage levels regularly with a multimeter and perform load tests to assess health. Be aware of common issues like sulfation, which can hinder performance. By applying these strategies, you can effectively charge and maintain your reconditioned batteries. Curious about more detailed methods and tips? There's plenty more to explore!

Key Takeaways

- Ensure you use the correct charger compatible with the specific battery type, whether lead-acid or lithium-ion, for effective reconditioning.

- Implement a controlled conditioning charge, starting below maximum capacity to prevent overcharging and damage during the reconditioning process.

- Utilize desulfation techniques, such as high-frequency pulses, to break down lead sulfate crystals and restore battery capacity.

- Conduct regular cycle charging and full discharge cycles to promote even cell voltage and enhance overall battery performance.

- Monitor voltage levels and perform load tests after charging to assess battery health and capacity post-reconditioning.

Methods of Reconditioning

When it comes to reconditioning batteries, various effective methods can help restore their performance and longevity.

For lead-acid batteries, desulfation is a key technique. By using a desulfator device, you can send high-frequency pulses through the battery, breaking down lead sulfate crystals that accumulate over time. This process restores the battery's capacity and maintains performance. Battery reconditioning is essential for prolonging the lifespan of these batteries and reducing the need for replacements.

Another method is equalization charging, which involves a controlled overcharge to balance the cells. This is particularly important for flooded lead-acid batteries, as it helps prolong their lifespan and ensures all cells are equally charged.

Additionally, don't forget about water addition; regularly checking and adding distilled water can prevent water loss and maintain optimal electrolyte levels, essential for battery health.

For lithium-ion batteries, balancing cells is crucial. Using a specialized charger ensures each cell charges evenly, preserving overall health.

You might also consider cycle charging, which involves fully charging and discharging the battery multiple times to restore capacity.

Lastly, managing temperature during charging and discharging helps prevent damage and prolongs the lifespan of your batteries.

Safety Precautions

Battery safety is paramount during the reconditioning process to prevent accidents and injuries. First, ensure you have adequate ventilation to avoid hydrogen gas buildup. Keep the area clear of flames, burning cigarettes, or any ignition sources.

Always raise the lid or open the doors of the battery compartment before charging to allow fresh air exchange. Store batteries upright and ensure the vent caps are tight. Avoid leaning over the battery when charging or maintaining it, and keep metal jewelry and tools away.

Use insulated tools to prevent sparks and have proper fire protection and emergency equipment ready. Wear splash-proof, polycarbonate goggles with ANSI safety designation Z-87 and gloves to protect against acid spills or electrical shocks. Remove all metal jewelry and avoid placing metal objects near the battery.

When connecting charger leads, remember to connect positive to positive and negative to negative. Make sure the leads are securely clamped before turning on the charger. Short-circuiting can release significant energy, leading to burns or explosions, so handle connections with care.

Always switch off the charger before disconnecting the leads, and allow vented batteries to stand for at least 20 minutes post-charging to ensure safety.

Charger Requirements

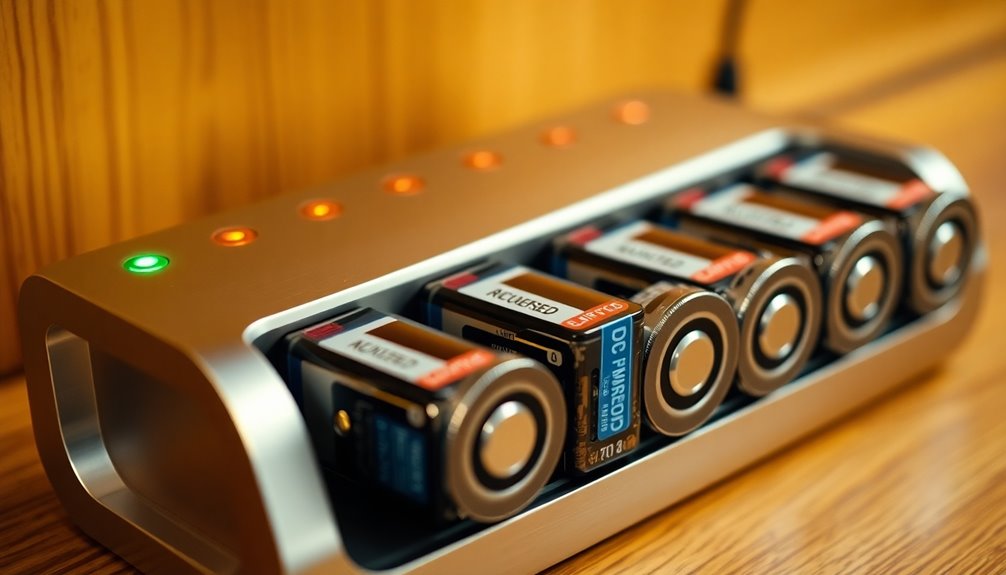

Choosing the right charger is crucial for effectively reconditioning batteries. You need to consider the type of battery you're working with. For lead-acid batteries, make sure your charger is compatible with Calcium, Gel, and AGM types. Many chargers, like the MBC 1205 and MBC 1220 models, are designed to be suitable for various battery capacities from 35-100Ah and 134-400Ah, respectively.

If you're dealing with lithium-ion batteries, specialized chargers are essential because they're designed specifically for those cells.

Look for chargers that offer automatic charging features. Fully automatic chargers with microprocessor control provide precise charging, which is vital for optimal battery health.

If you prefer more control, consider a charger with manual selection options for recondition mode tailored to specific battery types.

Additionally, choose chargers that support multiple input voltages, such as 220-240V AC or 110V AC, to ensure versatility.

It's also important to find chargers with multiple charging stages, including desulfation and float stages, as these enhance reconditioning efficiency.

Don't overlook safety features like over-voltage protection and temperature control. These will help protect both the charger and the batteries.

Finally, ensure the charger complies with relevant standards, guaranteeing quality and performance while reconditioning your batteries.

Charging Techniques

Understanding the right charger sets the foundation for effective charging techniques. Start by fully discharging the battery before initiating the reconditioning process. Once it's fully discharged, let it rest for a few hours to a day. This helps balance the cell voltages.

Next, initiate a conditioning charge at a controlled current and voltage that's below the maximum capacity. Keep a close eye on the charging process to avoid overcharging, which can lead to safety risks. Capacity loss due to aging and improper charging habits can significantly impact the battery's performance, so using the right techniques is crucial.

For lead-acid batteries, employ bulk, absorption, and float charging stages, or equalization if necessary. Smart chargers with microprocessor control can help regulate this process. If you're dealing with sulfated batteries, continue charging after a normal cycle to implement equalization.

Always prioritize safety. Keep open flames away, wear protective gear, and ensure your charging plugs are securely locked. After charging, switch off the charger before disconnecting leads.

Let the battery stand for at least 20 minutes, then top up the electrolyte with distilled water as needed. Following these techniques will help you maximize the lifespan and performance of your reconditioned batteries.

Testing and Maintenance

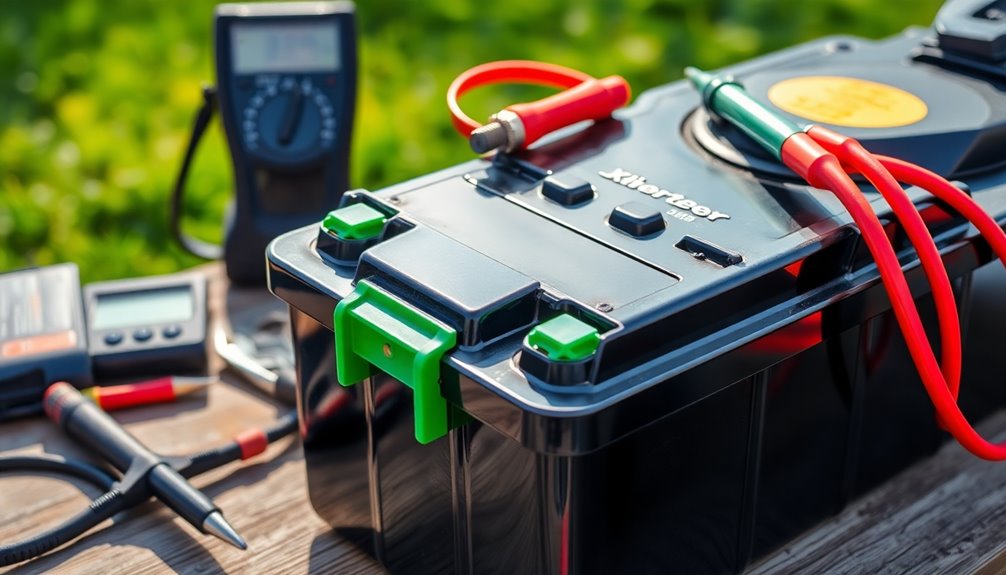

Effective testing and maintenance are crucial for ensuring your reconditioned battery performs optimally and lasts longer. Start by measuring voltage with a multimeter; normal readings for a car battery should be around 12.42V after charging. Regular voltage checks help identify any imbalances. Additionally, reconditioning can restore up to 80% of battery capacity, significantly enhancing battery performance.

Next, conduct a load test to simulate actual operation conditions, providing a realistic measure of battery capacity and health. This is especially important after reconditioning.

You should also measure internal resistance using an ohmic test to spot corrosion or mechanical defects. High resistance can indicate the battery's nearing end of life. Full cycle testing, involving charging, discharging, and recharging, gives the most accurate assessment of capacity and corrects any tracking errors.

Maintenance plays a key role too. Clean the battery regularly to prevent grime and corrosion. For flooded lead-acid batteries, check and maintain water levels, adding distilled water after charging.

Don't forget about equalization charging to restore cell balance and capacity. Finally, allow the battery to cool before removal and turn off power once fully charged to prevent overheating.

Common Issues

Many users encounter common issues when charging reconditioned batteries, which can hinder performance and longevity. One major problem is using a bad or incorrect charger. If your charger isn't compatible with your battery type, it won't charge effectively. Additionally, a poor connection between your charger and battery can disrupt the charging process. You should always inspect the wires for damage and ensure they're securely connected.

Another issue stems from the condition of the battery itself. Old or deeply discharged batteries may struggle to accept a charge, and damaged terminals can prevent proper contact. Sometimes, batteries require a full discharge before they can be charged again efficiently. It's essential to regularly monitor battery performance to detect any potential issues early.

You should also consider charger settings. Using the wrong mode, like neglecting reconditioning mode, can impact charging efficiency. Environmental factors, such as extreme temperatures, can further complicate matters, affecting both performance and charging capability.

Lastly, keep an eye on your charger's fuse and ensure it's intact, as a blown fuse can halt the charging process altogether.

Sulfation Solutions

Sulfation is a common issue that can significantly affect the performance of reconditioned batteries. It occurs when lead sulfate crystals build up on the battery plates, often due to incomplete charging, overcharging, or storing the battery without a full charge.

To prevent sulfation, you should store your batteries at full charge and keep them in temperatures below 75°F. Regular maintenance charging helps keep the voltage above 12.4 volts, while avoiding deep discharges can also reduce the risk. Additionally, it's important to remember that all lead-acid batteries naturally accumulate sulfation over time, which underscores the need for proactive measures.

If sulfation has already set in, there are methods to reverse the damage. Intermittent high-current pulses during charging can help break down the sulfate crystals.

Using specialized chargers that pulse high current through the battery can also aid in desulfation. Raising the battery temperature to around 50–60°C can further assist in this process.

For a temporary performance boost, consider adding Epsom salt to the electrolyte, as it can dissolve some of the lead sulfate buildup.

Acid Stratification Remedies

Addressing acid stratification is crucial to maintaining the health and performance of your reconditioned batteries. This issue arises when heavier acid separates from water, causing areas of high and low specific gravity within the cells. To combat this, ensure you conduct regular and fully saturated charging cycles. This helps maintain a uniform acid distribution, reducing the likelihood of stratification.

Operating your batteries at moderate temperatures and avoiding deep discharges can also mitigate the effects of acid stratification. Extreme temperatures and prolonged standing periods can worsen the problem, so keep your batteries in a stable, moderate environment. Additionally, rhythm** in charging patterns can enhance the overall efficiency of battery performance.

Additionally, proper handling and maintenance prevent long-standing periods that contribute to stratification. Consider using advanced battery technologies that actively prevent acid stratification. For instance, MIXTECH technology by Discover Battery is specifically designed to maintain uniform acid distribution, which can significantly extend the life of your flooded lead-acid batteries.

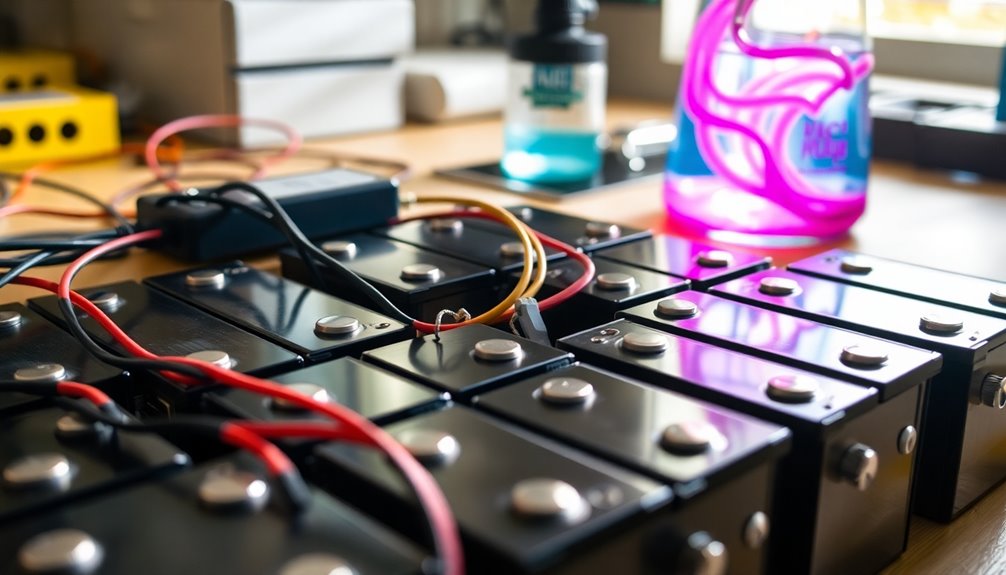

Managing Cell Imbalance

Cell imbalance can severely impact the performance of your reconditioned batteries, leading to reduced capacity and shorter runtimes. Several factors contribute to this issue, including manufacturing variations and differences in self-discharge rates.

When cells age unevenly due to temperature differences or inappropriate charging methods, some cells drain faster than others, exacerbating the imbalance. This cell imbalance can significantly limit the overall capacity to the weakest cell, affecting runtime.

To manage cell imbalance, start using a Battery Management System (BMS). This technology helps maintain equal charge levels across all cells.

Balancing chargers are also essential; they ensure that every cell receives a proper charge. Regular cycle charging and discharging can restore balance and capacity, while equalization charging can help lead-acid batteries regain equilibrium.

Temperature management is crucial, too. Keeping your batteries within optimal temperature ranges during charging and discharging prevents uneven aging.

Don't forget to use tools like multimeters to check voltage levels and ascertain cell balance. By implementing these strategies, you can significantly improve the lifespan and efficiency of your reconditioned batteries, reducing the risks associated with cell imbalance, like overheating and accelerated degradation.

Frequently Asked Questions

How Long Does the Reconditioning Process Take?

The reconditioning process can take anywhere from a few hours to over 12 hours, depending on the type of battery and its condition.

For instance, two-way radio batteries might require a specific manual process that lasts up to 12 hours, while hybrid car batteries may take several days.

It's essential to monitor the battery's status throughout to ensure you're following the right steps for effective reconditioning.

Can I Recondition Any Type of Battery?

You can recondition some types of batteries, but not all.

Lead-acid, nickel-cadmium, nickel-metal hydride, and lithium-ion batteries can often be reconditioned with the right methods. Each type has its specific reconditioning techniques, so you'll need to understand their unique requirements.

However, be cautious, as some batteries may not respond well to reconditioning or could pose safety risks. Always ensure you're following proper procedures to avoid accidents during the process.

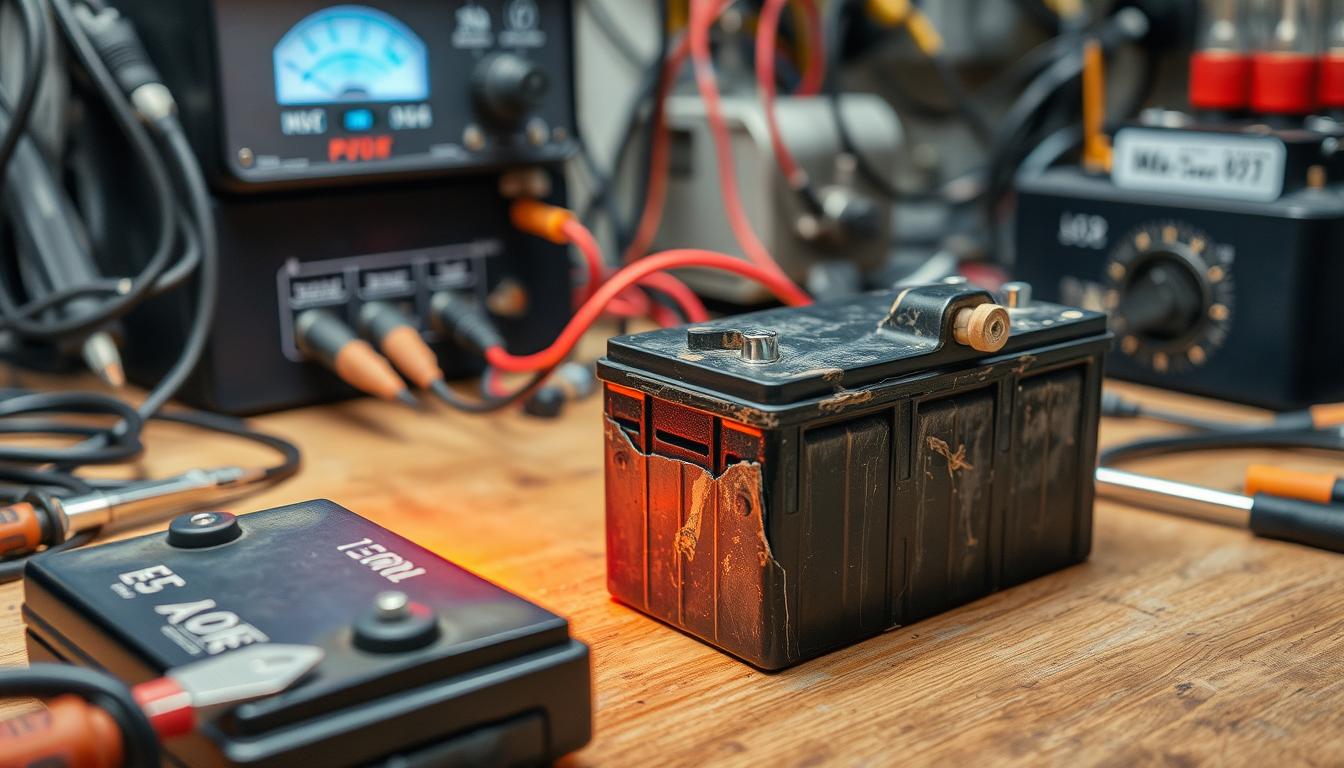

What Signs Indicate a Battery Cannot Be Reconditioned?

When assessing a battery, look for signs that it can't be reconditioned.

If you notice a swollen case, visible leakage, or corrosion around terminals, those are red flags.

Diminished cranking power and frequent jump starts indicate electrical failure.

Additionally, if you smell a rotten egg odor or see lead sulfate crystals, the battery's likely degraded.

If it's over six years old and shows these signs, it's probably time to replace it.

Is Reconditioning Safe for Sealed Batteries?

Reconditioning sealed batteries isn't generally safe due to the risks involved.

When you modify or recharge them, you can create venting issues or even cause explosions from gas buildup.

If you try drilling for maintenance, you might damage internal components or lose electrolyte.

It's crucial to understand the battery's structure and follow strict safety precautions.

If you're unsure, it's better to consult an expert or consider replacement instead.

Will Reconditioning Extend My Battery's Lifespan Significantly?

Yes, reconditioning can significantly extend your battery's lifespan.

By restoring the cells to their original condition, it reverses damage and enhances performance. You'll notice improved efficiency, reduced charging times, and a decrease in the need for frequent replacements, ultimately saving you money.

Additionally, reconditioning contributes to environmental sustainability by minimizing electronic waste.

Regular maintenance after reconditioning ensures you keep enjoying these benefits long-term.

Conclusion

In conclusion, reconditioning your batteries can breathe new life into them, saving you money and reducing waste. By following the right methods, taking safety precautions, and using appropriate chargers, you can effectively revive your batteries. Remember to test and maintain them regularly, address common issues like sulfation and acid stratification, and manage cell imbalance to ensure optimal performance. With a little effort, you'll keep your batteries running longer and more efficiently. Happy reconditioning!