Battery remanufacturing involves collecting used batteries, testing their condition, and refurbishing viable units by disassembling, cleaning, and replacing worn parts. It recovers valuable materials like lithium and cobalt, reducing environmental impact and preventing waste from landfills. This process saves energy, cuts costs, and extends battery life, making high-quality batteries more affordable. By supporting recycling and resource conservation, it benefits both you and the planet. To discover how this process works and its advantages, keep exploring further.

Key Takeaways

- The process involves testing, disassembly, refurbishment, and recycling to extend battery life and ensure safety.

- Remanufacturing recovers valuable materials, reducing the need for raw resource extraction and environmental impact.

- It conserves energy and lowers manufacturing costs by reusing components and materials.

- Proper safety protocols protect workers and prevent environmental hazards during collection, testing, and processing.

- Benefits include extended battery usability, lower costs, reduced pollution, and a smaller ecological footprint.

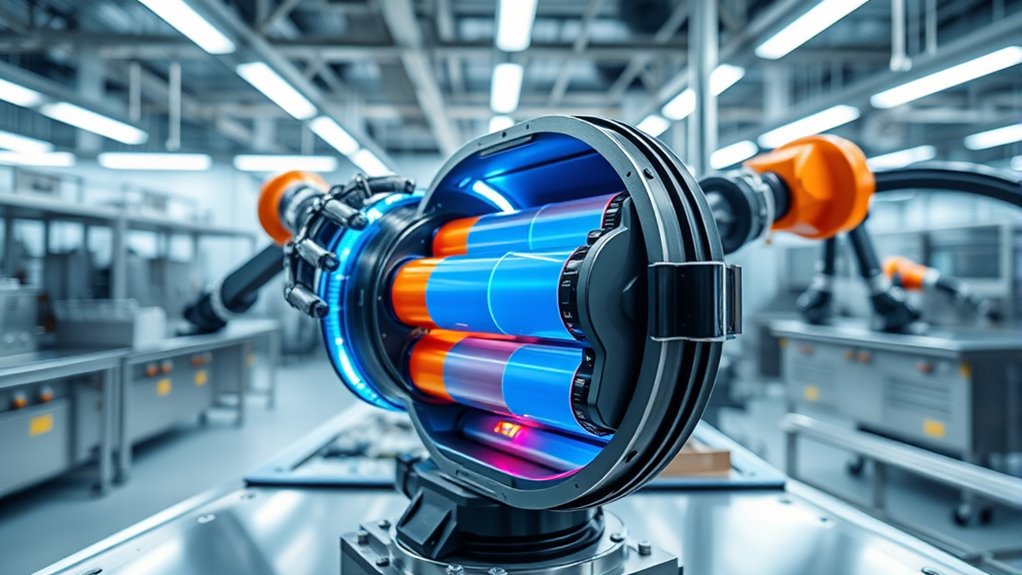

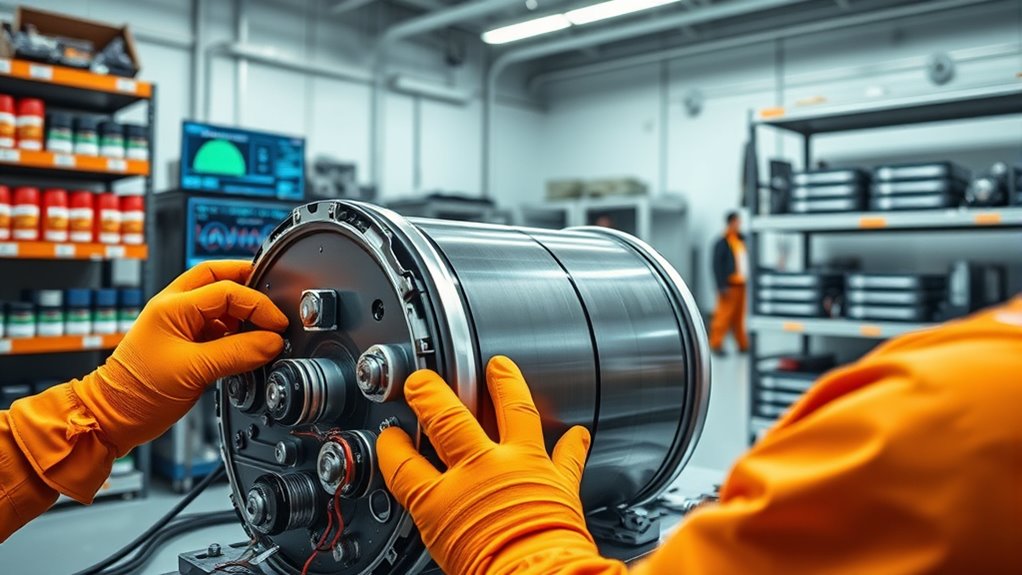

Have you ever wondered what happens to your used batteries once they’re no longer useful? Many people toss them in the trash, unaware that these small items have a substantial impact on the environment if not properly managed. That’s where battery remanufacturing comes into play, offering a sustainable solution that extends the life of batteries and reduces waste. The process begins with collection, where used batteries are gathered from various sources like households, businesses, and recycling centers. Once collected, they undergo thorough testing to determine their condition and whether they can be refurbished or need to be dismantled for parts. This step ensures that only batteries with potential for remanufacturing proceed further, optimizing resource use and minimizing waste. Proper safety protocols are essential throughout the process to protect workers and the environment. Battery recycling is a critical component of this process, allowing valuable materials such as lithium, cobalt, nickel, and lead to be recovered and reused. Instead of ending up in landfills, these materials are extracted and processed to create new batteries or other products, considerably reducing the need for mining raw materials. This approach not only conserves natural resources but also diminishes the environmental impact associated with extracting and processing these materials. By recycling batteries, you help reduce pollution, lower greenhouse gas emissions, and prevent harmful chemicals from leaching into the soil and water, which can pose health risks to communities and ecosystems. Once the batteries are disassembled, the reusable components are cleaned, tested, and refurbished. They undergo quality control to ensure they meet safety and performance standards before being remanufactured into new or upgraded batteries. This process often involves replacing worn-out parts, reconditioning cells, and reassembling the battery pack. The benefit of remanufacturing batteries lies in its efficiency; it conserves energy compared to manufacturing new batteries from raw materials and reduces manufacturing costs. For you, this means access to more affordable, high-quality batteries with a smaller environmental footprint.

Frequently Asked Questions

What Types of Batteries Can Be Remanufactured?

You can remanufacture various battery types, including lithium-ion, nickel-metal hydride, and lead-acid batteries. The process involves analyzing battery chemistry and applying specialized recycling processes to recover valuable materials. By remanufacturing these batteries, you extend their life, reduce waste, and support sustainability. Each battery chemistry requires tailored recycling processes, ensuring efficient material recovery and improved performance for reuse or resale.

How Cost-Effective Is Battery Remanufacturing Compared to New Batteries?

You’ll find that battery remanufacturing is quite cost-effective compared to buying new batteries, offering significant cost savings. It often requires less material and energy, reducing overall expenses. Plus, remanufactured batteries enhance market viability by providing a sustainable, affordable option for consumers and businesses. This approach not only cuts costs but also encourages eco-friendly practices, making it a smart choice for those seeking both savings and environmental benefits.

What Environmental Benefits Does Battery Remanufacturing Provide?

Imagine the impact if every used battery was remanufactured instead of discarded. You’d markedly boost recycling efficiency and slash pollution levels. Battery remanufacturing reduces waste, prevents toxic materials from contaminating the environment, and conserves resources. This process helps keep hazardous substances out of landfills and lowers the need for new raw materials. By choosing remanufacturing, you’re actively contributing to a cleaner, healthier planet, making a real difference today.

How Long Does the Remanufacturing Process Typically Take?

The remanufacturing process usually takes a few days to a week, depending on the battery’s condition and the remanufacturing equipment used. You’ll find that thorough quality control measures are essential to guarantee safety and performance. As you oversee the process, you’ll see how efficient procedures and proper equipment can speed up turnaround times while maintaining high standards, ultimately delivering reliable, eco-friendly batteries for your needs.

Are Remanufactured Batteries Covered by Warranties?

Think of remanufactured batteries as a well-repaired ship ready to sail again. Yes, they usually come with warranty coverage, giving you peace of mind. The quality assurance process guarantees the battery meets high standards before it reaches you, so you can trust its performance. Always check specific warranty terms, but generally, remanufactured batteries are protected, just like new ones, for a certain period.

Conclusion

Think of battery remanufacturing as giving a tired traveler a new lease on life, rejuvenating their journey. By refurbishing batteries, you’re not only extending their lifespan but also reducing waste and environmental impact. It’s a cycle of renewal that transforms used batteries into valuable resources, much like turning discarded pages into a compelling story. Embrace remanufacturing to keep the energy flowing sustainably and confidently into the future.