You won't believe it, but lithium is the key mineral used to make batteries today! This powerhouse is essential for powering everything from electric vehicles to smartphones. With the demand skyrocketing—expected to hit up to 450,000 tonnes by 2030—lithium's significance can't be overstated. It's not just lithium, though; cobalt and nickel also play important roles in enhancing battery performance. However, mining these minerals comes with environmental challenges that need addressing. Curiously, innovations are emerging to tackle these issues and improve sustainability. Stick around, and you'll uncover even more fascinating insights about battery minerals and their future!

Key Takeaways

- Lithium is the primary mineral used in lithium-ion batteries, essential for powering electric vehicles and electronics.

- Cobalt and nickel are also crucial minerals that enhance battery performance and energy density.

- The demand for lithium is projected to reach 250,000 to 450,000 tonnes by 2030 due to EV adoption.

- Environmental concerns include excessive water usage and potential contamination from lithium mining processes.

- Innovations in sustainable practices are being developed to minimize the environmental impact of battery mineral extraction.

Importance of Battery Minerals

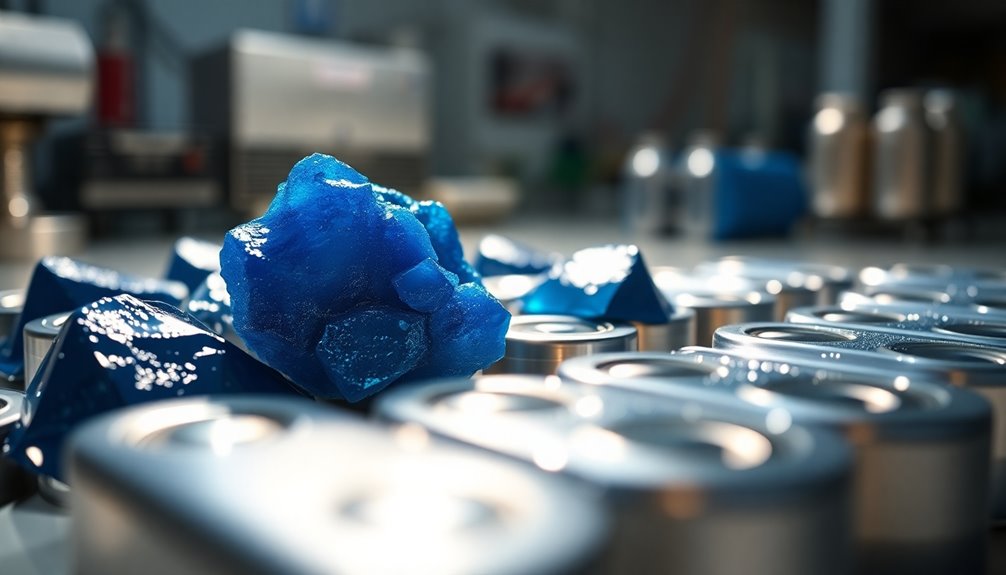

As the world shifts toward electric vehicles and renewable energy, the importance of battery minerals like lithium and graphite can't be overstated.

Lithium serves as the primary mineral resource for lithium-ion batteries, which power not just electric vehicles but also smartphones and laptops. With the demand for lithium projected to soar to between 250,000 to 450,000 tonnes by 2030, mining companies face increasing pressure to meet this need.

Each electric vehicle requires around 8 kilograms of lithium, highlighting the significant resource demands tied to widespread EV adoption.

Additionally, graphite enhances battery performance as an electrode material.

As the electric battery revolution progresses, prioritizing sustainability and responsible sourcing of these minerals will be critical for the industry's future.

Key Mineral: Lithium

Lithium is vital for powering the devices you use every day, but mining it isn't without challenges.

You might be surprised to learn about the environmental impacts and the innovations aimed at making extraction more sustainable.

As the demand grows, understanding these factors becomes essential for a balanced future.

Lithium Mining Challenges

While the demand for lithium surges due to the rise of electric vehicles, the challenges of mining this vital resource become more pronounced.

The average lithium mine takes several years to become operational, and with global production at only 113,000 tonnes in 2022, it's hard to keep up with projections of 250,000 to 450,000 tonnes by 2030.

You'll find that lithium mining often leads to environmental sustainability concerns, such as excessive water usage and potential groundwater contamination.

Additionally, the industry faces scrutiny over human rights abuses, particularly in regions where mining operations disrupt local communities.

Addressing these challenges through technological advancements in extraction and recycling is essential for a sustainable future.

Environmental Impact Concerns

Mining for lithium, essential for powering electric vehicles, raises significant environmental concerns that can't be ignored.

The extraction processes at lithium mines consume thousands of gallons of water per minute, with operations like the Silver Peak lithium mine drawing nearly four billion gallons annually. This raises alarms about water scarcity in drought-prone areas.

Additionally, the environmental impacts include groundwater contamination from harmful substances like antimony and arsenic, leading to potential ecological disasters.

You also face biodiversity loss, soil erosion, and air quality degradation as a result of these mining activities.

Unfortunately, outdated regulations often fail to protect the environment adequately, risking long-term damage to soil and water quality essential for sustainable lithium-ion battery production.

Innovations in Lithium Extraction

As the demand for electric vehicles surges, innovative approaches to lithium extraction are emerging to address environmental concerns.

Manitoba, Canada, is leading the way with a renewable lithium mining operation that harnesses hydroelectric power, eliminating diesel equipment for a more sustainable extraction process.

New methods in lithium mines also focus on minimizing water usage by returning mineral-rich brine underground post-extraction, tackling significant ecological issues.

In addition, advancements in lithium recycling enhance efficiency, potentially prolonging resource lifespan and reducing the need for new mining operations.

Collaborative efforts between industries and environmentalists are essential for developing sustainable mining practices that mitigate ecological impacts.

Ongoing research plays a fundamental role in balancing resource demand with ecological preservation, ensuring a greener future.

The Role of Graphite

Graphite plays an essential role in battery technology, especially in lithium-ion batteries, due to its remarkable conductivity. As a crystalline form of carbon, graphite serves as a key component in the production of electric batteries, greatly enhancing their performance.

Its excellent conductivity makes it an ideal material for electrodes, ensuring efficient energy transfer. With the rising demand for electric vehicles, the need for high-quality graphite is increasing, emphasizing its importance in the battery industry.

Mining graphite typically occurs in metamorphic rocks, utilizing both open-pit and underground operations. This process highlights graphite's status as a valuable natural resource, vital not only for batteries but also for various other applications, including lubricants and nuclear reactors.

Cobalt and Nickel Resources

Cobalt and nickel are essential players in battery technology, greatly boosting energy density and performance.

You'll find that cobalt, mainly sourced from the Democratic Republic of Congo, provides stability and longevity to batteries.

Meanwhile, nickel's rising demand reflects its vital role in powering the electric vehicle revolution and enhancing overall battery efficiency.

Cobalt's Role in Batteries

While you may not realize it, cobalt plays an essential role in the performance of lithium-ion batteries, which power everything from electric vehicles to your favorite gadgets. This critical component enhances energy density and stability, making it crucial for efficient battery operation.

Approximately 60% of the world's cobalt supply comes from the Democratic Republic of the Congo, sparking concerns about ethical mining practices and environmental impacts. On average, lithium-ion batteries contain about 10 to 20% cobalt by weight, underscoring its significance in production.

With innovations targeting cobalt-free alternatives, the industry is working to address supply chain risks. As cobalt and nickel often coexist in ore deposits, sustainable sourcing and recycling of these materials have become increasingly important for battery performance.

Nickel's Importance for Performance

As the demand for electric vehicles surges, nickel's importance in lithium-ion batteries becomes increasingly evident. This metal plays a significant role in enhancing battery performance, particularly in the cathodes.

By incorporating nickel, batteries can achieve higher energy density and storage capacity, allowing electric vehicles to travel farther on a single charge.

However, the growing need for nickel raises supply chain challenges, especially as cobalt and nickel resources are often sourced through deep-sea mining, which poses environmental risks.

As innovations in battery technology continue, there's a push to find alternatives to reduce reliance on these minerals.

Ultimately, nickel remains essential for the future of electric vehicles and the development of more efficient battery systems.

Environmental Concerns in Mining

Environmental concerns in mining, particularly for lithium, are increasingly pressing as demand for battery materials rises. Lithium mining operations consume thousands of gallons of water per minute, raising alarms about groundwater depletion, especially in drought-prone areas.

The extraction processes also pose serious ecological risks, including groundwater contamination with harmful substances like antimony and arsenic. Additionally, the environmental impacts extend beyond water; they include biodiversity loss, soil erosion, and degraded air quality from dust and emissions.

Current mining regulations often lack adequate environmental protections, leading to long-term soil and water quality degradation from toxic waste. Effective tailings management is essential, as poorly managed mining waste can contaminate distant water sources and harm local ecosystems, threatening both wildlife and communities.

Innovations in Battery Technology

Innovations in battery technology are reshaping the future of energy storage, particularly as the demand for sustainable solutions grows. Researchers are focusing on reducing lithium consumption per unit and exploring solid-state and iron-based battery technologies. These advancements could lessen reliance on traditional lithium-ion batteries and extend the lifespan of lithium resources.

Here's a quick overview of current innovations:

| Innovation Type | Description |

|---|---|

| Solid-State Batteries | Use solid electrolytes for improved safety and performance. |

| Iron-Based Batteries | Offer a more sustainable alternative to lithium-ion. |

| Lithium Recycling | Enhances efficiency to reduce waste and prolong resource availability. |

| Collaborative Efforts | Foster sustainable practices in manufacturing and sourcing. |

Future of Battery Resource Management

With the rapid growth of electric vehicle (EV) adoption, managing battery resources effectively is more important than ever. The demand for lithium is projected to soar, reaching between 250,000 to 450,000 tonnes by 2030.

While innovations in battery technology might reduce the average lithium requirement per EV, the pressure on lithium resources will still be significant. To combat this, increased efficiency in lithium recycling is essential. By enhancing recycling methods, you can extend the lifespan of lithium resources and lessen reliance on new mining operations.

Strategic planning and responsible sourcing are critical for a sustainable shift to an electrified economy. Collaboration between industries and environmentalists will help address extraction challenges and guarantee environmentally sound practices in lithium mining.

Frequently Asked Questions

Which Mineral Resources Are Used to Make Batteries?

When you think about battery production, several mineral resources come to mind.

Lithium is an essential element, powering everything from smartphones to electric vehicles with its lightweight and high energy storage capacity.

You can't overlook graphite either, which enhances both heat and electricity conduction as an electrode material.

Cobalt and nickel also play important roles, sourced from both deep-sea nodules and traditional mining, reflecting the growing demand for sustainable battery solutions.

Which Mineral Resource Is Used to Make Batteries Graphite Gypsum Talc Cla?

When it comes to batteries, graphite's practically the superstar of minerals!

You'll find it's essential for lithium-ion batteries, thanks to its incredible conductivity and stability. Without graphite, those batteries wouldn't perform nearly as well.

While cobalt and nickel also play important roles, graphite's the one you can't overlook.

As electric vehicles gain popularity, the demand for this mineral is skyrocketing, making it vital for a sustainable future in battery technology.

Which of the Following Minerals Is Used in Batteries?

When you think about minerals used in batteries, lithium, graphite, and cobalt stand out.

Lithium's lightweight and high energy storage make it essential for efficient battery performance.

You'll find graphite as a key component for electrodes, providing excellent electrical conductivity.

Cobalt adds stability and enhances energy density, particularly in lithium-ion batteries.

As electric vehicle demand grows, understanding these minerals is vital for sustainable sourcing and recycling practices in battery production.

What Resource Is Used in Batteries?

When you're thinking about what resource is used in batteries, lithium stands out. It's essential for powering many devices, from smartphones to electric vehicles.

You might be surprised by the demand; an electric vehicle requires about 8 kilograms of lithium!

But it doesn't stop there—graphite, cobalt, and nickel also play significant roles in enhancing battery performance.

As the market for electric vehicles expands, the need for these materials is only going to grow.

Conclusion

In a world racing towards electrification, battery minerals are the unsung heroes, dazzling with their importance! Lithium zips you into the future, while graphite glides smoothly alongside. Cobalt and nickel join the party, crafting power like superheroes! But beware—the mining landscape is a wild jungle, fraught with environmental challenges. Yet, with innovations popping up like popcorn, the future of battery resource management promises to be nothing short of a thrilling rollercoaster ride you won't want to miss!