Starting a mobile battery reconditioning service is a fantastic opportunity to serve a growing market. You'll need essential equipment like multimeters, smart chargers, and safety gear. Focus on mastering reconditioning techniques for different battery types, especially lead-acid and lithium-ion. Completing training programs and obtaining certifications will enhance your credibility. You'll attract customers from various sectors, including healthcare and automotive, all seeking cost-effective solutions. Plus, the environmental benefits of your service will resonate well with eco-conscious clients. If you want to know more about setting up operations and effective marketing strategies, keep exploring the possibilities your business can offer.

Key Takeaways

- Invest in essential equipment such as testing tools, smart chargers, and safety gear for effective battery reconditioning operations.

- Obtain proper training and certifications to enhance credibility and ensure proficiency in battery reconditioning techniques.

- Establish a mobile service vehicle equipped with necessary tools for convenience and accessibility to customers.

- Focus on environmental benefits to attract eco-conscious customers and promote sustainable practices in battery management.

- Implement targeted marketing strategies, including digital marketing and local community engagement, to build a customer base.

Market Overview

As the demand for cost-effective and sustainable battery solutions rises, the mobile battery reconditioning service market is rapidly expanding. By 2024, this global market is expected to be valued at $4.2 billion, with projections reaching $6.5 billion by 2030—a growth rate of 7.7%.

You'll find that this surge is mainly driven by increased adoption of electric vehicles and renewable energy systems, highlighting the necessity for efficient battery management. Notably, the process of refurbishing worn-out batteries to restore performance is a critical aspect of this service, which directly contributes to reducing electronic waste.

Regions like North America are poised to hold the largest market share, thanks to their robust automotive and industrial sectors. The strong culture of maintenance and compliance with environmental regulations boosts the appeal of battery rebuilding services.

Meanwhile, the Asia Pacific region is on track for impressive growth, spurred by booming sectors in countries like China and India.

As you explore this market, you'll notice a clear push toward reducing electronic waste and embracing circular economy principles.

While challenges exist, such as misconceptions about rebuilt batteries, the opportunities are vast. Expanding into sectors like aerospace and healthcare could enhance your service offerings and market reach, making this a promising venture for aspiring entrepreneurs.

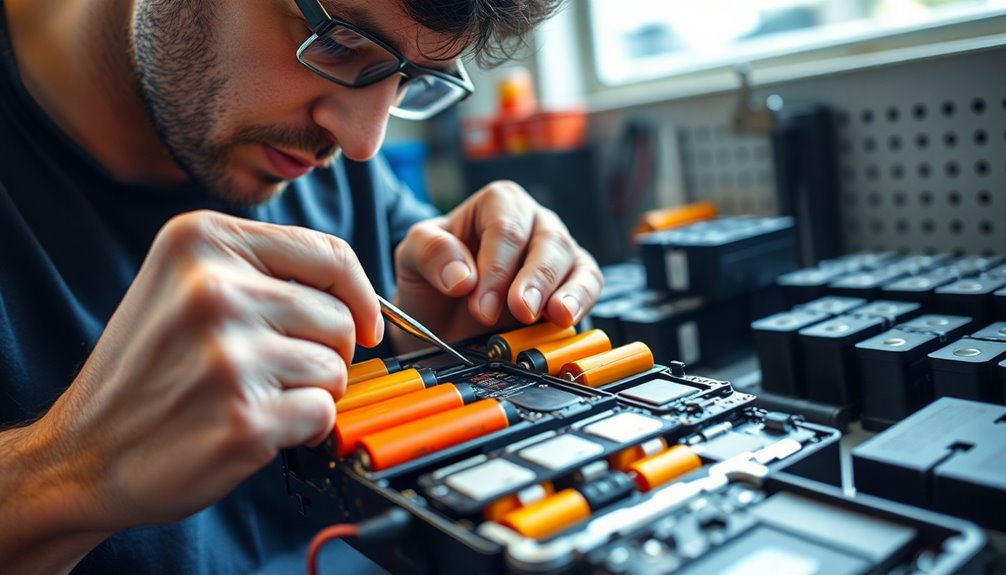

Essential Equipment

To successfully operate a mobile battery reconditioning service, you'll often rely on a variety of essential equipment. First, invest in measurement and testing tools like a multimeter, load testers, and hydrometers. These tools help you assess battery health, diagnose issues, and check electrolyte density.

Don't forget voltage meters and battery post cleaners to ensure your work is precise and efficient. Additionally, understanding the battery chemistry can enhance your ability to identify specific reconditioning needs.

Next, you'll need charging and maintenance equipment. Smart battery chargers revitalize batteries, while desulfators remove harmful buildup in lead-acid types. Power supply units (PSUs) offer stable power sources, and battery capacity testers measure overall health.

Keep electrolyte refills handy for any necessary top-ups. Safety is paramount, so equip yourself with acid-resistant gloves, safety goggles, and face masks to shield yourself from chemicals and fumes. Ensure proper workshop ventilation to create a safe working environment.

Finally, stock up on hand tools and accessories. Screwdrivers, wrenches, and wire cutters are essential for handling batteries, while syringes help with adding water to flooded cells. Paper towels and battery casing removal tools will keep your workspace organized and efficient.

Reconditioning Techniques

With the right equipment in hand, you can employ various reconditioning techniques to extend the life of batteries. Start by focusing on lead-acid batteries.

Always wear gloves and goggles for safety, and work in a well-ventilated area. Use a desulfator device to break down lead sulfate crystals, connecting it as per the manufacturer's instructions. Monitor the process to avoid overvoltage. This is crucial as sulfation occurs when batteries discharge, leading to longer charging times and reduced efficiency.

For equalization charging, use a smart charger to slightly overcharge the battery, ensuring you check the voltage regularly to maintain it between 13-14 volts. Don't forget to check the electrolyte levels and add distilled water as needed.

When it comes to lithium-ion batteries, safety is paramount. Use a specialized charger to balance the cells and monitor the charging process carefully.

Cycle charging and discharging can help restore performance, so repeat this a few times while keeping an eye on the temperature.

Lastly, conduct performance testing through load tests after several cycles. Document your results, as this will help you refine your techniques and improve your reconditioning skills over time.

Economic Advantages

How can mobile battery reconditioning services benefit your wallet? First off, you'll save significantly on battery replacement costs. By extending the life of existing batteries, you minimize the need for new purchases, which can quickly add up. This is especially true for hybrid batteries, where replacement can run into thousands of dollars.

Quick restoration of battery functionality also reduces downtime costs, helping you avoid lost productivity. Additionally, offering mobile services opens up unique revenue streams. You can attract a dedicated customer base seeking convenience and affordability. Competitive pricing makes your service appealing, while partnerships with auto repair shops and environmental organizations can expand your reach.

Operational efficiency plays a crucial role too. With on-site reconditioning, turnaround times decrease, saving time for both you and your customers. Utilizing advanced technology ensures high-quality results, boosting customer satisfaction and loyalty. Moreover, this service extends the usable life of existing batteries, making it a smart choice for both sustainability and cost-effectiveness.

Lastly, you gain a competitive advantage by differentiating your service from traditional battery replacements. This not only positions you as a reliable and innovative solution but also attracts customers looking for long-term savings and extended battery life. It's a win-win for both your business and your clients.

Environmental Benefits

Sustainability emerges as a crucial factor when considering mobile battery reconditioning services. By opting for reconditioning, you significantly reduce your environmental footprint—up to 90% less than traditional mining methods. This process consumes much less energy, too, with some techniques using up to 90% less than current standards.

Reconditioning not only minimizes the need to extract raw materials, which often harms the environment, but also conserves essential resources. By recycling materials from old batteries, you retrieve valuable metals like lithium, cobalt, and nickel, which are often much more concentrated than in newly mined ores. This practice helps preserve these finite resources for future generations and meets the growing demand without additional mining. According to the Australian Battery Recycling Initiative, proper recycling also prevents hazardous waste from entering landfills, reducing the risk of toxic metals leaking into the soil and waterways. It protects communities from potential mercury poisoning and aligns with consumer expectations for sustainable practices.

With advancements in recycling efficiency, such as newer methods that restore batteries to near-original capacity, you can contribute to a cleaner planet while enjoying the benefits of a responsible service. Embracing mobile battery reconditioning is more than a business choice; it's a commitment to environmental stewardship.

Required Skills

A successful mobile battery reconditioning technician needs a diverse set of skills to thrive in this growing industry. First, you must have a solid understanding of various battery types, like lead-acid and lithium-ion, and be familiar with their testing procedures, such as voltage and load testing.

Mastering the use of specialized tools—like a battery hydrometer and voltmeter—is essential for effective diagnostics. You should also develop strong diagnostic skills to identify issues, like corrosion on terminals or sulfation in cells, and know how to clean and adjust electrolyte levels. This will help you determine the feasibility of reconditioning a battery.

Safety is crucial in this field. You'll need to understand safe handling procedures for batteries and chemicals while using proper safety gear like gloves and glasses. Being aware of potential hazards, including explosions and electrical shocks, is vital to protect yourself and your clients. Additionally, staying updated with industry trends will enhance your ability to adapt to new techniques and technologies in battery reconditioning.

Lastly, business and customer service skills are key. Effective communication and marketing will help you attract customers, while managing expectations and delivering quality service will build your reputation as a trusted expert in mobile battery reconditioning.

Training and Certification

To succeed as a mobile battery reconditioning technician, it's important to not only have the right skills but also undergo proper training and certification. Engaging in a Battery Technician Program can provide you with fundamental knowledge in designing, operating, and maintaining battery cells and packs. This program includes 25 content hours of hands-on lab experience, ensuring you understand battery characteristics and safe handling practices. Additionally, the training emphasizes safe handling of battery systems, which is crucial for personal and environmental safety.

For more specialized training, consider enrolling in the Hybrid Lithium and NiMH Battery Testing series, which offers insights into battery systems and diagnostic techniques, culminating in a certificate of completion.

If you're focused on electric vehicles, the 2025 EV Lithium-ion Battery Repair training provides in-house classes that cover practical skills like battery pack dismantling and repair.

Certifications such as the NuVant Systems Certification and the Lithium-Ion Battery Repairing Certification from the Academy of EV Technology further validate your expertise and legal obligations in battery handling.

These credentials not only boost your professional credibility but also enhance your capabilities, making you a more competitive player in the mobile battery reconditioning market.

Target Customer Segments

Identifying target customer segments is crucial for the success of your mobile battery reconditioning service. You'll want to focus on several key areas.

First, hospitals and clinics require reliable energy solutions due to high energy consumption from medical devices. Offering battery reconditioning can help these facilities save costs while reducing electronic waste, aligning with their sustainability goals. Additionally, battery rebuild services can extend the operational life of medical devices, which is critical for healthcare facilities.

Next, consider manufacturing and industrial facilities that rely on battery-powered equipment. These businesses need cost-effective battery management to minimize operational expenses and extend battery life. Your service can provide a significant environmental benefit by reducing battery disposal.

Don't overlook the automotive sector. Auto repair shops and car owners are prime customers for battery reconditioning, as it allows them to restore battery functionality and save money on new purchases. You can also highlight the environmental advantages of minimizing waste.

Lastly, target consumers and electronic device users, especially those looking for affordable options to prolong their devices' life. This segment is often environmentally conscious, making your service appealing.

Setting Up Operations

When setting up operations for your mobile battery reconditioning service, it's essential to focus on acquiring the right equipment and tools. Invest in battery reconditioning units like the NuVant EVc-12 or EVc-30, which provide full state-of-health reports. Additionally, utilizing an EVc Battery Reconditioner will simplify the battery reconditioning and cell balancing processes.

For lead-acid batteries, consider machines like the Xtender that can discharge, desulfate, and restore them efficiently. Make sure you have the necessary electrical connections, such as a 220 V connection with a NEMA L6-30 outlet.

You'll also need accessory tools like adjustable torque drills, QR code readers, and battery pack cooling boxes. Integrate battery monitoring systems for detailed diagnostics to enhance your service.

Establish a mobile service vehicle equipped with all necessary tools, and set up a well-ventilated workshop for in-house operations. Ensure that both setups have the required power and cooling infrastructure.

Organize storage for batteries and equipment to maintain efficiency. Finally, prioritize safety by using protective gear and ensuring proper ventilation when handling batteries.

With the right foundation, you'll be well on your way to delivering top-notch mobile battery reconditioning services.

Marketing Strategies

Effective marketing strategies are crucial for the success of your mobile battery reconditioning service, especially since you want to connect with local customers. Start by conducting thorough market research to identify customer demographics and preferences. This insight will help you tailor your marketing messages to address their pain points effectively.

Focus on local markets, as most of your customers will likely be nearby.

Leverage digital marketing by utilizing social media platforms like Facebook and Instagram to engage your audience. Share educational content, such as blog posts and videos, that inform customers about battery reconditioning. Implement SEO strategies to enhance your online visibility and use targeted ads to broaden your reach. Additionally, consider performing competitor analysis to identify successful strategies and gaps in the market.

Building community relationships is vital. Participate in local events and consider partnering with local businesses to cross-promote services. Engage through sponsorships or workshops that promote battery recycling.

Lastly, prioritize exceptional customer service. Maintain transparent communication throughout the process and follow up to ensure satisfaction. Offering promotions and loyalty programs can also attract new customers while encouraging repeat business.

Use testimonials to build trust and credibility with potential clients, solidifying your brand's reputation in the community.

Frequently Asked Questions

What Types of Batteries Can Be Reconditioned?

You can recondition several types of batteries, including lead-acid, nickel-cadmium (NiCd), nickel-metal hydride (NiMH), and lithium-ion.

Lead-acid batteries often suffer from sulfation, while NiCd batteries may experience the memory effect.

NiMH batteries require balancing and careful handling, and lithium-ion batteries need cell balancing and temperature management.

How Long Does the Reconditioning Process Take?

The reconditioning process can take several hours to a couple of days, depending on various factors.

You'll first fully discharge the battery, which might require a few hours for rest.

After that, you'll cycle through conditioning charges and discharges multiple times, each taking several hours.

Finally, you'll perform a full recharge.

Temperature, charge rates, and battery type also influence how long the entire process will take, so keep those in mind.

What Is the Expected Lifespan of Reconditioned Batteries?

When you recondition batteries, you can expect their lifespan to extend significantly, sometimes by up to six years.

The methods you use, like cleaning sulfate crystals and replenishing the electrolyte solution, play a crucial role. Your battery's age, temperature, and depth of discharge also impact how long it'll last.

While reconditioned batteries may not last as long as new ones, proper care can help maximize their longevity and performance.

Are There Warranties for Reconditioned Batteries?

Yes, there are warranties for reconditioned batteries.

Typically, they offer coverage for 12 months or 15,000 miles for high-grade remanufactured hybrid batteries.

However, the warranty may be voided if you misuse the battery or fail to maintain it properly.

To claim a warranty, you'll need diagnostic paperwork from a certified facility and might be responsible for return shipping if the battery's functioning correctly.

Always check specific terms before making a purchase.

Can Mobile Services Cater to Commercial Clients?

Yes, mobile services can definitely cater to commercial clients.

You can provide convenience by going directly to their locations, saving them time and transportation costs. Many businesses, like auto repair shops, appreciate the flexibility of on-site service.

Conclusion

Starting a mobile battery reconditioning service can be a rewarding venture. By understanding the market, investing in essential equipment, and mastering reconditioning techniques, you'll set yourself up for success. Not only will you enjoy economic advantages, but you'll also contribute to a greener environment. With the right training and targeted marketing strategies, you can attract a loyal customer base. Embrace this opportunity, and watch your business thrive while making a positive impact!