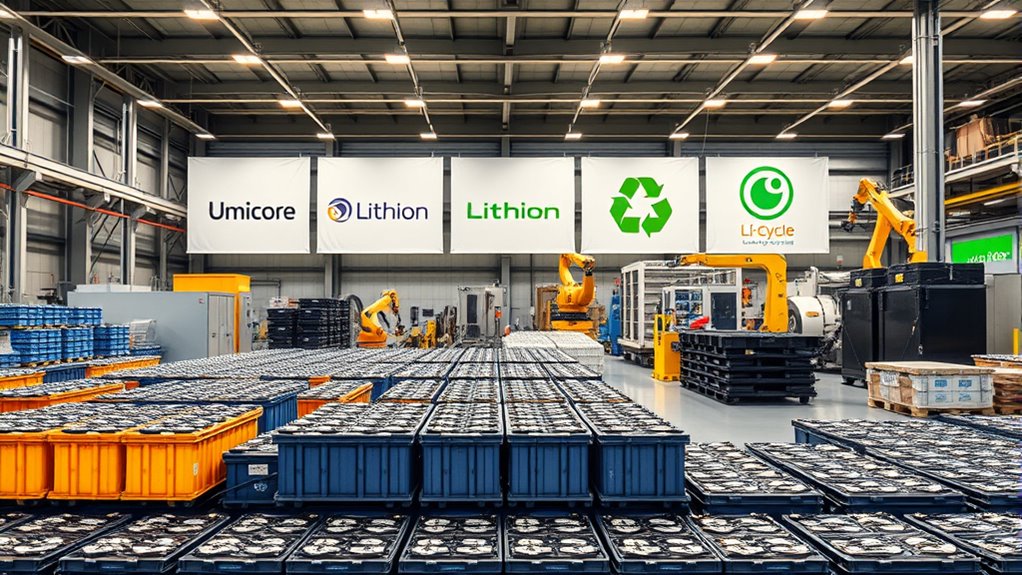

Aside from Umicore, Lithion, and Li‑Cycle, other key recyclers are making significant strides in battery recycling technology. These companies focus on recovering valuable metals efficiently and sustainably, helping to reduce reliance on raw materials and lower environmental impact. Their innovations aim to create a circular economy for batteries, making recycling more cost-effective and eco-friendly. If you want to explore how these organizations are shaping the future of resource management, there’s more to discover ahead.

Key Takeaways

- Umicore, Lithion, and Li‑Cycle are leading companies specializing in innovative battery recycling technologies.

- Umicore focuses on recovering valuable metals like cobalt, nickel, and lithium from used batteries.

- Lithion emphasizes sustainable lithium recovery, minimizing energy and chemical use in waste processing.

- Li‑Cycle develops efficient separation methods to recycle end-of-life electric vehicle batteries.

- These companies aim to create a circular economy, reducing environmental impact and supporting sustainable energy solutions.

Have you ever wondered which other key players help keep our planet clean through recycling? Companies like Umicore, Lithion, and Li‑Cycle are leading the charge, transforming how we handle waste and reuse materials. These organizations focus heavily on battery material recovery, a vital element in reducing environmental impact and supporting the shift toward sustainable energy. Their innovations in recycling technology are pushing the boundaries of what’s possible, making the process more efficient, cost-effective, and environmentally friendly.

Umicore stands out as a pioneer in this space, leveraging advanced recycling technology innovations to recover valuable metals from used batteries. Instead of letting these materials go to waste, Umicore’s process extracts essential components like cobalt, nickel, and lithium, which can be reused in new batteries. This not only lessens the need for mining new raw materials but also considerably reduces the carbon footprint associated with raw material extraction. Their expertise in battery material recovery means that they can process a high volume of spent batteries efficiently, turning potential waste into valuable resources. This approach exemplifies how recycling technology innovations can revolutionize waste management, making it a sustainable cycle rather than a linear one.

Umicore recovers valuable metals from used batteries, transforming waste into resources and reducing the need for new raw materials.

Lithion is another key player that’s making waves with its focus on innovative recycling solutions. Specializing in lithium recovery, Lithion employs cutting-edge techniques to extract lithium from spent batteries and other waste streams. Their process emphasizes sustainability, aiming to minimize energy consumption and chemical use while maximizing recovery rates. By refining these technologies, Lithion helps create a circular economy for lithium, which is critical given its widespread use in electric vehicle batteries and portable electronics. Their advancements support the broader goal of reducing reliance on environmentally damaging mining practices, making the entire supply chain more sustainable. Additionally, their focus on advanced recovery methods underscores their commitment to transforming waste into a resource.

Li‑Cycle also contributes notably to the battery recycling ecosystem, emphasizing the importance of integrating recycling into the supply chain early on. They develop technology that allows for efficient separation and recovery of battery materials, especially from end-of-life electric vehicle batteries. Their innovations in recycling technology enable the recovery of a broad range of metals with high purity, ensuring these materials can be reused in new batteries without extensive processing. By focusing on battery material recovery, Li‑Cycle helps close the loop, reducing waste and conserving resources, which aligns perfectly with global efforts to combat climate change.

Frequently Asked Questions

How Do These Recyclers Compare in Processing Capacities?

You’ll find that these recyclers vary in processing capacities, impacting battery material recovery and supply chain integration. Umicore leads with a high throughput, making it ideal for large-scale recovery efforts. Lithion and Li‑Cycle have more specialized, flexible operations suited for specific markets. Their capacities influence how quickly they can process used batteries, affecting the efficiency of the supply chain. Your choice depends on your scale and the urgency of battery material recovery needs.

What Innovative Recycling Technologies Do They Use?

You’re likely interested in their innovative recycling tech. These companies excel in advanced methods like hydrometallurgical processes, which improve battery material recovery while minimizing environmental impact. They also utilize proprietary sorting and separation techniques to boost efficiency and guarantee regulatory compliance. With over 90% of battery components being recyclable, their technologies are key to sustainable, safe recycling that meets global standards. This innovation drives the future of responsible battery lifecycle management.

How Do They Ensure Environmental Sustainability?

You guarantee environmental sustainability by focusing on efficient battery material recovery and adhering to strict regulatory compliance. By implementing advanced recycling processes, you minimize waste and reduce hazardous emissions. You also stay updated on environmental standards, ensuring your methods meet or exceed regulations. This commitment helps conserve resources, lowers ecological impact, and promotes a circular economy, making your recycling operations both eco-friendly and sustainable.

What Are Their Main Challenges in Battery Recycling?

You face challenges like optimizing battery material recovery efficiently while ensuring strict regulatory compliance. As you work to improve recycling processes, you must navigate evolving laws and standards, which can complicate operations. Balancing cost-effectiveness with environmental impact also poses difficulties, requiring innovative solutions. Staying ahead in technology and regulations is essential, so you can maximize material recovery and meet sustainability goals without falling behind.

How Do They Collaborate With Automakers and OEMS?

You collaborate with automakers and OEMs by integrating into the battery supply chain, ensuring efficient recycling processes. You work closely to develop sustainable practices, share expertise, and optimize material recovery. Additionally, you stay aligned with regulatory compliance, which helps streamline operations and build trust. This partnership enables a more circular approach to battery materials, reducing environmental impact and securing a steady supply of recycled resources for future vehicle production.

Conclusion

So, as you marvel at the recycling giants like Umicore, Lithion, and Li-Cycle, remember—they’re not just saving the planet, but also turning leftover batteries into gold. Who knew that discarded tech could be such a lucrative treasure hunt? Next time you toss that outdated gadget, just think: you’re fueling a high-stakes recycling adventure, where the real winners are the companies making a killing while Mother Earth gets a green makeover. Cheers to eco-friendly capitalism!