3D-printed jigs make cell replacement procedures much easier by providing customized guides that fit perfectly to your patient’s anatomy. They improve accuracy, speed up treatments, and reduce the chance of errors. Made from biocompatible materials, these jigs integrate smoothly with tissue and support better outcomes. Streamlining workflows, they also help you achieve consistent results. Keep exploring to discover how these innovative tools can revolutionize your regenerative therapies.

Key Takeaways

- Customized 3D-printed jigs ensure precise and consistent cell placement, streamlining regenerative procedures.

- Biocompatible materials minimize immune responses, promoting seamless integration with patient tissue.

- Rapid prototyping and complex design capabilities reduce procedure times and enhance accuracy.

- Tailored fit to individual anatomy improves stability, making cell replacement more efficient.

- Simplified workflows and on-demand production support faster, less invasive regenerative treatments.

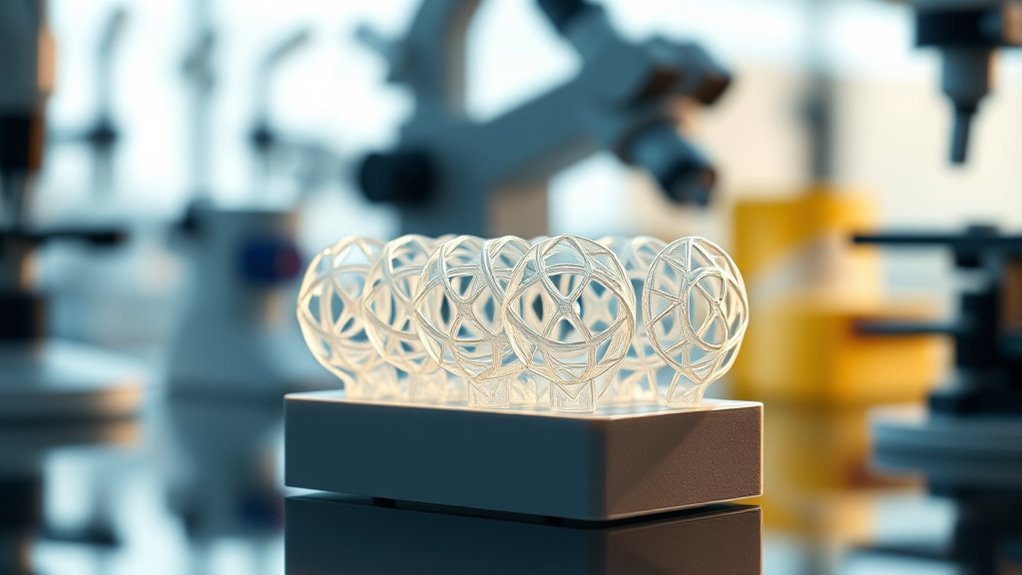

Advancements in 3D printing technology are revolutionizing the field of regenerative medicine, especially in cell replacement therapies. One of the most exciting developments is the creation of 3D-printed jigs that streamline and improve the precision of these complex procedures. These jigs serve as customized guides, helping you position cells accurately and consistently, which is vital for successful tissue regeneration. The key to their effectiveness lies in the use of biocompatible materials that are safe to use within the human body. These materials are designed to minimize immune responses and guarantee that the jigs don’t interfere with the healing process. By choosing the right biocompatible substances, you can achieve a seamless integration between the device and the patient’s tissue, reducing the risk of complications and promoting faster recovery.

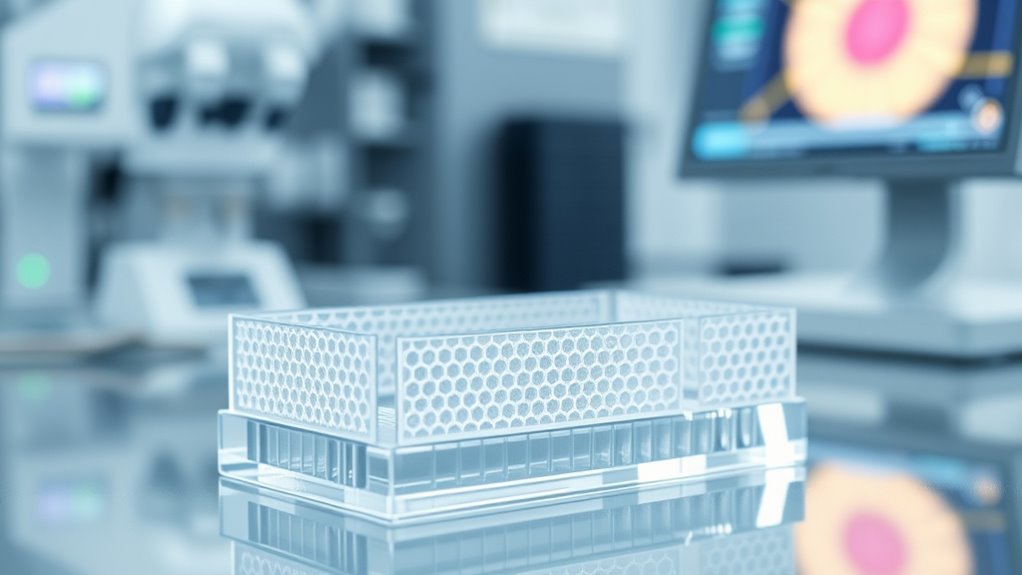

Manufacturing precision is at the core of these 3D-printed jigs. Unlike traditional manufacturing methods, 3D printing allows you to produce highly detailed and complex designs tailored specifically to each patient’s anatomy. This means you can create custom jigs that fit perfectly, providing stability and accuracy during cell placement. The precision offered by 3D printing ensures that cells are deposited exactly where they need to be, improving the overall outcome of the therapy. It also enables rapid prototyping, so you can quickly test and refine designs to optimize performance. This level of customization not only enhances the success rate of cell transplantation but also reduces procedure times, making treatments more efficient and less invasive. Additionally, the ability to incorporate advanced materials into the jigs further enhances their functionality and integration within regenerative procedures.

Using 3D-printed jigs also simplifies what used to be a labor-intensive process. Instead of relying on manual adjustments and guesswork, you now have a tool that guides your hand and guarantees consistency across procedures. The workflow becomes more streamlined, allowing for better reproducibility, which is essential in clinical settings. Furthermore, the ability to produce these jigs on-demand means that you can adapt designs swiftly for different patients or evolving treatment protocols. This flexibility accelerates the pace of innovation and makes advanced regenerative therapies more accessible.

Frequently Asked Questions

How Cost-Effective Are 3d-Printed Jigs for Large-Scale Production?

When considering the cost-effectiveness of 3D-printed jigs for large-scale production, you should weigh the initial cost analysis against long-term savings. While 3D printing reduces setup costs and allows rapid customization, scalability challenges can arise as production volume increases. However, with advances in materials and printing technology, you might find that these jigs become more economical over time, especially for complex or customized applications.

What Materials Are Used for 3d-Printed Jigs in Cell Replacement?

Think of 3D-printed jigs as the scaffolding of your biotech project. You’ll typically use biocompatible materials like medical-grade polymers (e.g., PEEK, ABS, or PLA) that guarantee safety and support cell growth. Printing precision is key, so you’ll want materials that allow detailed, accurate designs. These choices help you create reliable, effective jigs that seamlessly integrate with biological processes, making cell replacement smoother and more efficient.

How Long Does It Take to Design and Print a Jig?

When you consider the design process and printing speed, it typically takes a few hours to a couple of days to create a jig. You start by designing the jig using CAD software, which can take several hours depending on complexity. Once the design is finalized, printing speeds vary based on the printer and material, usually taking anywhere from a few hours to over a day to complete the print.

Are 3d-Printed Jigs Reusable for Multiple Procedures?

Using a 3D-printed jig is like having a trusty toolbox—you wonder if it’s reusable across multiple procedures. Generally, these jigs offer reusable versatility, but you face sterilization challenges. Proper cleaning and sterilization are essential to prevent contamination, so with careful maintenance, you can reuse them several times. Just keep in mind, their durability depends on the material and how well you handle sterilization processes.

What Are the Sterilization Protocols for 3d-Printed Jigs?

When sterilizing 3D-printed jigs, you need to consider sterilization methods and material compatibility. You should use methods like autoclaving, ethylene oxide, or UV sterilization, depending on the jig’s material. Always verify the material’s tolerance to heat or chemicals to avoid deformation or degradation. Follow manufacturer guidelines and regularly test sterilization efficacy to ensure safe, effective reuse without compromising the jig’s integrity or performance.

Conclusion

Imagine how these 3D-printed jigs could transform your cell replacement procedures, making them faster and more precise than ever before. With such innovative tools at your fingertips, do you really want to rely on outdated methods that slow you down? Embrace this technology and see your work become more efficient, accurate, and accessible. Isn’t it time you took the leap into the future of medical innovation? Your next breakthrough awaits with these game-changing jigs.