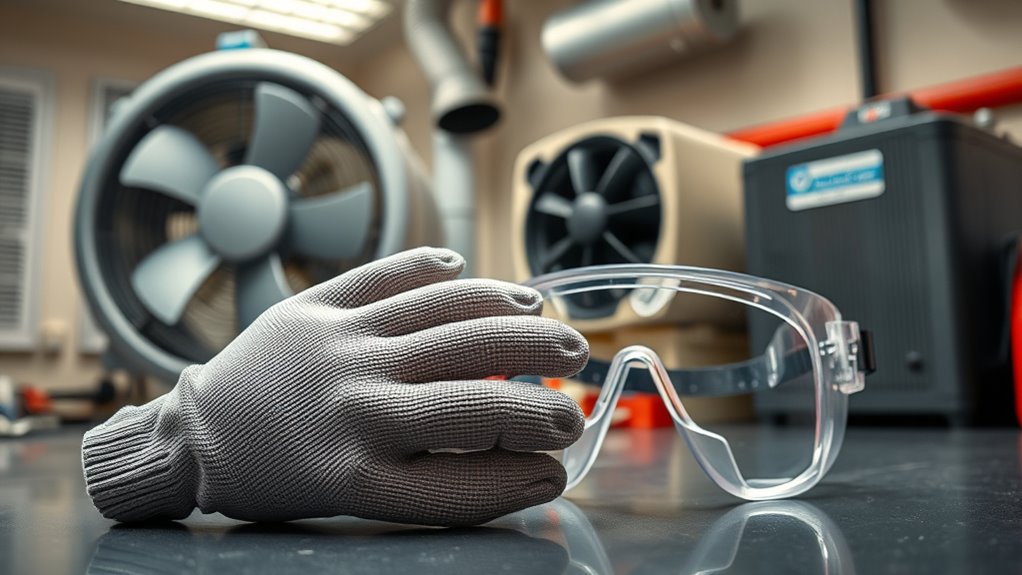

When reconditioning batteries, it’s vital that you wear proper safety gear like chemical-resistant gloves and goggles to protect your skin and eyes from corrosive acids and harmful fumes. Proper ventilation is also essential to disperse toxic gases such as hydrogen, which can build up during the process. Ensuring your workspace is well-ventilated and equipped with safety equipment helps prevent accidents. Keep paying attention, as there’s more to learn for a safe and effective battery reconditioning experience.

Key Takeaways

- Wear chemical-resistant gloves and goggles to protect skin and eyes from corrosive battery acids.

- Ensure proper workspace ventilation with exhaust fans or open windows to disperse toxic fumes.

- Use long-sleeved clothing and aprons to prevent acid burns and skin contact during reconditioning.

- Keep emergency supplies, like baking soda and a first aid kit, nearby for quick response to spills or injuries.

- Maintain an organized, well-ventilated workspace and avoid sparks or smoking near batteries for safety.

Reconditioning batteries can be a rewarding process, but it also involves risks that require proper safety measures. One of the most important steps you can take is wearing protective clothing. This gear acts as a barrier against harmful chemicals, acid splashes, and potential sparks. A long-sleeved shirt, chemical-resistant apron, and sturdy gloves are your first line of defense. Gloves made of rubber or latex help prevent skin contact with corrosive substances, while a long-sleeved shirt or lab coat reduces the chance of acid burns or irritation. Never underestimate the importance of protective clothing—it keeps you safe from unexpected accidents and minimizes the damage if something goes wrong.

Emergency preparedness is equally critical when reconditioning batteries. Before starting, ensure you have an accessible emergency kit nearby, including neutralizing agents like baking soda for acid spills, and know how to use them. Keep a clear plan in mind for dealing with chemical splashes or injuries. Having a phone nearby to call emergency services is essential. Always work in a well-ventilated area to reduce the buildup of hazardous fumes, and make sure your workspace is organized to avoid tripping hazards or accidental contact with battery terminals. Knowing how to respond quickly can make all the difference in minimizing harm if an accident occurs.

Proper ventilation is also key to safe battery reconditioning. Batteries, especially lead-acid types, release dangerous gases like hydrogen during charging or discharging. These gases are highly flammable and can cause explosions if accumulated in enclosed spaces. To prevent this, work in a space with good airflow—preferably with an exhaust fan or open windows—so fumes don’t concentrate. Never work in a confined or poorly ventilated area, and avoid smoking or creating sparks nearby. Ventilation helps disperse toxic vapors, reducing the risk of inhalation or fire. Additionally, understanding AI-driven safety monitoring technologies can enhance safety by alerting you to hazardous conditions in real time.

Frequently Asked Questions

Can Safety Gear Prevent All Battery-Related Accidents?

Safety gear can’t prevent all battery-related accidents, but it substantially reduces your risk. Wearing protective clothing, gloves, and goggles shields you from harmful chemicals and potential sparks. Additionally, being prepared for emergencies, like having a fire extinguisher nearby, is vital. While safety gear is essential, always follow proper procedures and stay alert to guarantee your safety during battery reconditioning. It’s about minimizing risks, not eliminating them entirely.

Is Specialized Ventilation Required for Specific Battery Types?

Yes, specialized ventilation is often necessary depending on the battery type. For example, lead-acid batteries release hydrogen gas, so you need proper ventilation to prevent buildup and reduce explosion risk. Lithium-ion batteries may emit harmful fumes if damaged or overheated, requiring adequate airflow. Always check the specific ventilation requirements for each battery type to guarantee safe reconditioning, and use appropriate safety gear alongside proper ventilation practices.

How Often Should Safety Gear Be Replaced or Inspected?

Imagine your safety gear as your shield in a storm—crucial and protective. You should inspect your gloves, goggles, and ventilation equipment before every use, ensuring they’re free of cracks, tears, or wear. Safety gear maintenance involves replacing items immediately if damaged or after prolonged use. Regular inspection frequency keeps your protective gear reliable, so you stay safe during battery reconditioning, preventing accidents and ensuring peace of mind.

Are There Any Safety Gear Options for Sensitive Skin?

If you have sensitive skin, look for hypoallergenic safety gear like gloves and goggles made from gentle, non-irritating materials. These options help prevent allergic reactions and skin irritation during battery reconditioning. Always choose gear labeled specifically for sensitive skin, and consider using barrier creams under gloves for extra protection. Regularly inspect your gear for signs of wear, replacing it promptly to maintain safety and comfort throughout your work.

Can Safety Equipment Be Reused After Reconditioning Sessions?

Think of safety equipment like a trusty sword—reusable safety equipment can be used again after reconditioning sessions if you perform proper safety gear maintenance. Regularly inspect gloves, goggles, and ventilation systems for wear or damage, replacing parts as needed. Keeping your safety gear in good shape guarantees ongoing protection, so you can confidently recondition batteries without risking exposure to harmful substances or compromising safety.

Conclusion

Remember, safety gear is your shield against the hidden dangers of battery reconditioning. Wearing gloves, goggles, and ensuring proper ventilation is like building a fortress around you—protecting you from sparks, acid splashes, and fumes. Don’t underestimate these precautions; they’re your first line of defense in a potentially risky process. Stay vigilant, stay safe, and treat your workspace like a minefield—careful steps keep you out of harm’s way.