When moisture enters your device, it creates tiny conductive paths between electrical contacts and components. This can happen through cracks, seal failures, or humidity buildup. The moisture allows electricity to flow where it shouldn’t, leading to internal short circuits. These shorts can cause device malfunctions, corrosion, or even permanent damage. Understanding how moisture causes these issues can help you protect your equipment; keep exploring to learn more about preventing these problems effectively.

Key Takeaways

- Moisture creates conductive paths by bridging electrical components, enabling unintended current flow.

- It reacts with metal parts, causing oxidation and corrosion that disrupt normal electrical connections.

- Water ingress increases internal resistance, leading to unpredictable electrical behavior and potential short circuits.

- Moisture accumulation in battery compartments can weaken connections and promote internal bridging.

- The presence of moisture lowers insulation resistance, heightening the risk of accidental electrical contact.

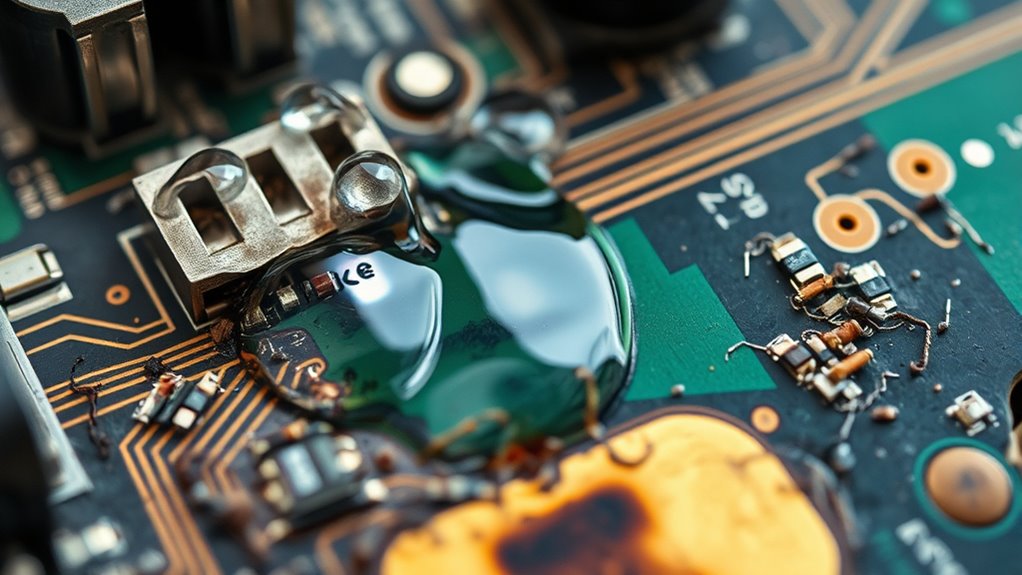

Moisture ingress is a common cause of electrical failures, leading to short circuits that can damage equipment and pose safety risks. When water or humidity find their way into electronic devices, they can create conductive paths where none should exist. This often happens in areas with inadequate sealing or compromised protective barriers. One essential step you can take to mitigate this risk is proper battery sealing. Making certain that batteries are well-sealed prevents moisture from reaching internal components, which is crucial because moisture inside a battery can lead to corrosion and increased electrical resistance. Corrosion prevention through effective sealing not only extends the lifespan of your equipment but also maintains its reliability.

When moisture enters a device, it interacts with metallic parts, causing oxidation and corrosion. Corrosion weakens connections and can create unpredictable electrical pathways, increasing the likelihood of a short circuit. This is especially true in battery compartments where moisture can accumulate unnoticed. Proper battery sealing acts as a barrier, keeping moisture out and preventing these adverse reactions. Using high-quality seals, gaskets, and waterproof enclosures ensures that water cannot penetrate sensitive areas. Regular inspection of seals for cracks or degradation is essential because even small gaps can allow moisture to seep in over time.

In addition to sealing, corrosion prevention measures are essential in maintaining the integrity of electrical components. Applying corrosion inhibitors or protective coatings can add an extra layer of defense. These coatings repel moisture and inhibit oxidation, reducing the risk of internal shorts. For batteries, this might involve specialized sealants around terminals or the use of corrosion-resistant materials during manufacturing. Keeping the environment dry and controlling humidity levels also supports corrosion prevention efforts. Implementing preventative maintenance routines can help identify early signs of seal degradation or corrosion buildup before failure occurs.

It’s also important to think about the quality of materials used in sealing and corrosion prevention. Cheap or improperly applied seals may fail prematurely, allowing moisture ingress and setting the stage for short circuits. Similarly, neglecting maintenance or ignoring signs of seal deterioration can lead to costly failures. Implementing a routine inspection schedule ensures that seals remain intact and corrosion does not develop unnoticed. When you pay attention to these protective measures, you greatly reduce the chances of moisture-related short circuits, making sure your equipment remains safe, reliable, and long-lasting.

Frequently Asked Questions

How Does Moisture Enter Sealed Battery Packs?

Moisture can enter sealed battery packs through ingress pathways like tiny cracks, vent holes, or imperfect seals. If the sealed enclosure isn’t perfectly airtight or develops damage over time, moisture finds its way inside. You might not see these entry points easily, but they allow humidity and water vapor to penetrate, leading to potential issues like corrosion or internal short circuits. Regular inspection and quality sealing are essential to prevent this.

Can Moisture Ingress Be Detected Early?

Surprisingly, detecting moisture ingress early isn’t as tricky as it sounds. You can rely on sensor alerts that monitor humidity levels and corrosion indicators that show early signs of internal damage. These tools notify you before a problem becomes critical, allowing proactive maintenance. So, while moisture might seem invisible, technology makes it easy to catch the troublemaker before it causes costly internal short circuits.

What Materials Resist Moisture Penetration Best?

You want to know what materials resist moisture penetration best. Material barriers like advanced polymers, ceramics, and coated metals effectively block moisture. Sealant effectiveness plays a vital role in preventing ingress; high-quality, waterproof sealants create tight seals around joints and edges. Using these materials and proper sealing techniques reduces moisture entry, protecting electronic components from damage and internal short circuits caused by moisture ingress.

How Do Environmental Changes Affect Moisture Levels?

Imagine you’re back in the days of ancient mariners, steering unpredictable weather. Environmental changes, like humidity fluctuations and temperature impacts, directly influence moisture levels around your device. When humidity rises or temperatures shift dramatically, moisture can seep in, risking internal short circuits. You need to monitor these conditions carefully, as even minor fluctuations can lead to serious damage, especially if your device isn’t well-sealed against environmental influences.

Are There Industry Standards for Moisture Resistance?

You should know that industry standards for moisture resistance exist to guarantee product reliability. These standards compliance guidelines specify testing protocols to evaluate how well devices resist moisture ingress. By following these protocols, manufacturers verify their products can withstand environmental conditions, reducing risks of internal short circuits. Ensuring adherence to these standards helps you maintain quality, safety, and longevity in your electronic devices.

Conclusion

Understanding how moisture ingress causes internal shorts is essential for device safety. Did you know that over 30% of electronic failures are linked to moisture-related issues? By keeping your devices dry and sealed, you can greatly reduce the risk of internal short circuits. Stay vigilant about moisture exposure, especially in humid environments, to protect your electronics and extend their lifespan. Remember, a small moisture breach can lead to costly damage—so stay proactive!