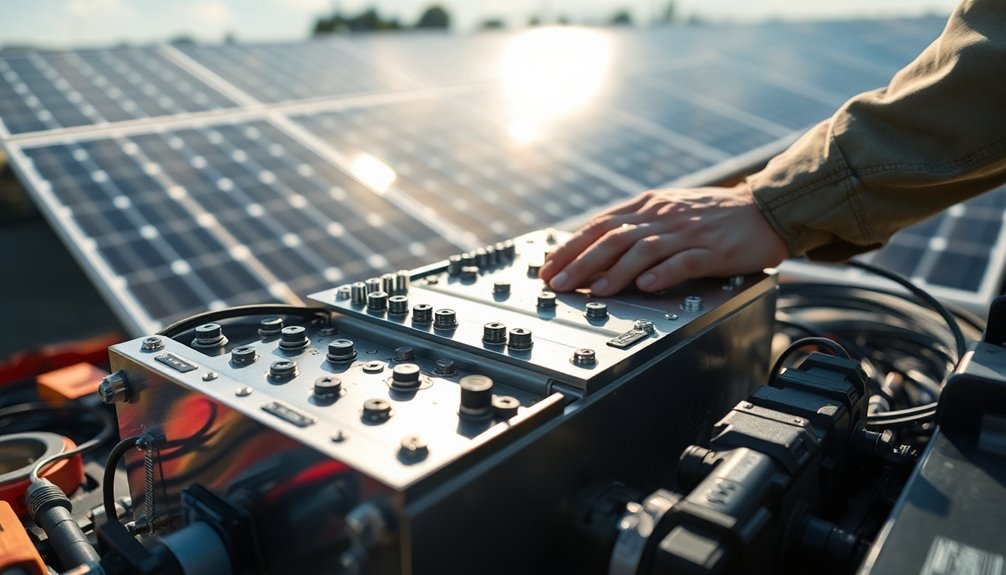

Reconditioning solar power storage batteries can greatly enhance their lifespan and efficiency. You should start by fully discharging the battery and then recharging it carefully to activate the lithium ions. Regularly conduct capacity tests and cycle tests to assess performance. Implementing proper charging techniques, like bulk and absorption charging, prevents overheating and maximizes capacity. You'll also want to monitor your battery's health by checking voltage levels and inspecting for any corrosion. With the right maintenance and techniques, you can keep your solar batteries in peak condition. Stay with us to uncover further tips and tricks for effective battery care.

Key Takeaways

- Regularly cycle the battery through controlled discharges and recharges to stabilize voltage and capacity, extending its lifespan.

- Conduct capacity testing to measure energy in watt-hours and determine overall battery health and reconditioning needs.

- Utilize proper charging techniques, including bulk, absorption, and float charging, to optimize battery performance and prevent overheating.

- Implement periodic inspections to check for corrosion, damage, and voltage levels, ensuring the battery remains in good condition.

- Store batteries in a cool, dry place to prevent deterioration and promote effective reconditioning during downtime.

Understanding Lithium-Ion Batteries

Understanding lithium-ion batteries starts with grasping their fundamental components and functionality. These batteries consist of two electrodes: the anode, which is negatively charged, and the cathode, positively charged. The electrolyte, a liquid or gel, plays a crucial role in conducting electricity between these electrodes, while a porous separator keeps them apart to prevent short circuits.

When you discharge a lithium-ion cell, lithium ions move from the anode to the cathode, generating a flow of electrons in the external circuit. This movement creates electrical current. During charging, the process reverses, with lithium ions migrating back to the anode. The separator and electrolyte facilitate this ion movement, ensuring efficient operation. Lithium-ion batteries are composed of single or multiple lithium-ion cells that function together to provide reliable power.

Lithium-ion batteries are known for their high energy density, offering up to 693 W⋅h/L and up to 270 W⋅h/kg in specific energy. Their efficiency during charging and discharging cycles ranges from 90-95%.

With low self-discharge rates and impressive cycle durability, these batteries are ideal for various applications, including portable electronics and electric vehicles. Understanding these basics lays the groundwork for exploring reconditioning techniques.

Battery Evaluation Techniques

Accurate battery evaluation is crucial for assessing the health and performance of lithium-ion batteries. Start with capacity testing by ensuring the battery is fully charged and has been unused for at least 24 hours. Connect a load to the battery and measure the time taken to discharge it to the required voltage. Record the total energy discharged in watt-hours (Wh) and repeat this process two to three times for reliability.

Next, move on to cycle testing. Set up your equipment, charge the battery fully using a solar panel, then discharge it to the lowest capacity before recharging it again. Repeat this cycle multiple times to gauge overall performance.

Don't overlook internal resistance and safety testing. Use pulse or AC impedance methods to measure internal resistance and check for potential issues. Conduct overcharge and short circuit tests to evaluate the battery's safety. Regular testing helps identify potential problems early, ensuring better battery reliability and longevity in the long run due to lower internal resistance.

For advanced evaluation, employ techniques like coulomb counting and electrochemical impedance spectroscopy (EIS) to gain deeper insights into the battery's state. Each of these methods provides vital information, helping you make informed decisions about reconditioning your solar power storage battery.

Discharge and Rest Process

Discharging and resting your solar power storage battery are critical processes that directly affect its performance and lifespan. When a load draws current from the battery, it's discharging, and the greater the current, the faster this happens.

Remember, batteries also experience idle discharge due to internal chemical reactions, which means they lose charge even when not in use. Idle discharge occurs when the battery remains connected but not actively supplying power.

To manage this discharge, consider using control methods like a Low Voltage Disconnect (LVD). This method prevents over-discharge by disconnecting the load at a set voltage, protecting the battery's health.

Be mindful of the Depth of Discharge (DOD)—regularly discharging beyond recommended levels can significantly shorten lifespan.

After discharging, a rest period is essential. During this time, the battery can recover and stabilize.

Keep an eye on factors like temperature, as they can impact both discharge and recovery.

To maintain battery health, you might want to apply a freshening charge to keep it close to full capacity, countering the effects of self-discharge.

Conditioning Charge Method

To effectively restore your solar power storage battery's performance, employing a conditioning charge method is essential. This method consists of several stages: bulk charging, absorption charging, float charging, and equalization charging.

First, during bulk charging, you deliver the maximum allowable current to bring the battery to 80-90% capacity. This stage increases the battery voltage to about 14.5 volts for a nominal 12-volt battery, rapidly transferring energy and recovering most of the battery's capacity, especially critical for deeply discharged batteries. It is important to note that this voltage increase is essential for rapid recharging of solar batteries.

Next, absorption charging kicks in when the battery is 80-90% charged. Here, you use constant-voltage regulation, reducing current as the battery nears full charge. This process prevents overheating and excessive gassing, ensuring the battery reaches a 98% state of charge or greater while stabilizing voltage and current levels.

After that, float charging maintains the battery at maximum capacity throughout the day by reducing the charging current. This prevents overcharging and prolongs the battery's life.

Lastly, if you have flooded open vent batteries, consider equalization charging every 2 to 4 weeks to break down sulfate crystals and equalize cell voltages, though avoid this for sealed batteries to prevent damage.

Cycle Charge and Discharge

When it comes to reconditioning solar power storage batteries, understanding the cycle charge and discharge process is crucial. You need to fully discharge the battery first, which can be done by connecting a resistive load to the terminals.

After discharging, let the battery rest for a few hours to balance the cell voltages. During discharge, keep an eye on the voltage to ensure it doesn't drop below a safe level, as this can vary by battery type.

Once you've discharged the battery, you'll recharge it at a controlled current and voltage. This step redistributes the energy within the battery, activating the lithium ions. It's important to monitor this process to avoid overcharging, which can damage the battery. Rechargeable power sources like lithium-ion batteries can benefit significantly from this process, leading to improved efficiency.

You may need to repeat these discharge and recharge cycles several times to stabilize the battery's voltage and capacity.

Keep in mind that the depth of discharge (DoD) affects the lifespan of your battery; aiming for a DoD between 40% and 80% can help extend its cycle life. By carefully managing these cycles, you'll enhance your battery's performance and longevity.

Post-Reconditioning Evaluation

Evaluating a solar power storage battery after reconditioning is essential to ensure its performance and longevity. Start by measuring the Round-Trip Efficiency (RTE), which for lithium-ion batteries typically ranges from 77% to 95%. A higher RTE means more energy is being effectively stored and retrieved, so aim for that 90% mark or above.

Next, assess the Coulomb Efficiency (CE), which reflects how well the battery stores and releases energy in a single cycle. Take note of degradation rates, which can vary significantly based on usage and age. Understanding these metrics can help you predict the battery's lifecycle, typically lasting between 10 to 20 years. Additionally, consider that energy storage is crucial for integrating renewable energy sources like solar, which enhances the overall sustainability of the system.

Also, evaluate how many charge-discharge cycles the battery can withstand before performance declines. This cycle life directly impacts its economic viability and return on investment (ROI).

Finally, consider environmental factors like temperature, as they can affect both efficiency and lifespan. By thoroughly evaluating these aspects, you'll gain a clearer picture of your battery's post-reconditioning performance and be better equipped to make informed decisions about its future use.

Ongoing Maintenance Practices

Regularly maintaining your solar power storage battery is crucial for maximizing its efficiency and lifespan. Start with periodic inspections to spot potential issues like corrosion or physical damage. Check battery terminals for wear, and use a multimeter to verify voltage levels. Infrared imaging can also help identify imbalances in current flow.

Next, keep your batteries clean to ensure optimal performance. Use a battery cleaning product or a homemade baking soda solution for terminal cleaning. For heavy corrosion, steel wool or sandpaper works well. Make sure the battery and its connections are free from dust and debris, and store them in a cool, dry place to avoid damage from extreme temperatures. Clean batteries improve solar energy storage and output efficiency, contributing to the overall effectiveness of your solar power system.

Don't forget about software updates and integration. Keeping your battery's software up-to-date enhances operational efficiency. Utilize monitoring systems for real-time data on battery health and enable remote access for timely interventions. Setting up automated maintenance alerts ensures your battery remains in prime condition.

Finally, practice preventative measures. Avoid overcharging, perform shallow cycle charges, and check for damage regularly. Proper storage away from direct sunlight and heat sources further extends your battery's life.

Frequently Asked Questions

Can Reconditioning Damage My Battery Further?

Yes, reconditioning can potentially damage your battery further. If the process isn't done correctly, it might lead to overheating or chemical imbalances, which can cause irreversible degradation.

You could end up with a battery that has a reduced capacity and requires more frequent charging. Additionally, safety risks like swelling or even thermal runaway can increase, especially if you're working with older or compromised batteries.

Always prioritize safety and proper techniques when reconditioning.

How Often Should I Recondition My Solar Power Batteries?

You should recondition your batteries regularly to maximize their lifespan.

For seasonal use, aim for this a couple of times a year, while full-time setups benefit from about four times annually.

If you're using a charge controller with auto-equalization, set it for every 30 to 60 days.

Consistent maintenance prevents sulfation, ensuring your batteries remain efficient and reliable.

Keep an eye on electrolyte levels and address any issues promptly.

What Tools Do I Need for Reconditioning?

To recondition batteries effectively, you'll need a few essential tools.

Start with a battery desulfator to remove sulfate build-up. You'll also require an Epsom salt solution for acid replacement, along with protective gear like gloves and goggles for safety.

A load tester and multimeter will help you check voltage and capacity after reconditioning.

Lastly, have chargers ready for equalization charges, ensuring your batteries are ready to perform at their best.

Is Reconditioning Safe for All Battery Types?

Reconditioning isn't safe for all battery types.

Lead-acid batteries can be reconditioned with caution, addressing issues like sulfation and overcharging.

However, lithium-ion batteries pose significant risks, like thermal runaway and fire hazards, making them trickier to handle.

If you're considering reconditioning, it's crucial to understand the specific safety concerns for each battery type.

Always follow best practices, monitor conditions, and use the right equipment to ensure safety during the process.

Can I Recondition a Completely Dead Battery?

You can attempt to recondition a completely dead battery, but success isn't guaranteed. The process may partially restore its capacity, depending on the type and extent of damage.

For lead-acid batteries, techniques like desulfation can help, while lithium-ion batteries might need balancing and cycling.

Keep in mind, though, that reconditioned batteries often won't last as long as new ones, so weigh your options before investing time and effort.

Conclusion

In conclusion, reconditioning your solar power storage batteries can significantly extend their lifespan and enhance performance. By understanding lithium-ion technology and employing evaluation techniques, you can effectively restore battery capacity. The discharge and rest process, along with conditioning charge methods, play crucial roles in the reconditioning cycle. Remember to regularly maintain your batteries to keep them in optimal condition. With these practices, you'll enjoy reliable energy storage for years to come.